Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap Price Steel H Beam for Building Details

Place of Origin: | China (Mainland) | Grade: | Q235 | Technique: | Hot Rolled |

Thickness: | 6-12mm | Application: | Steel Building Structure | Length: | 12m |

Standard: | JIS | Flange Width: | 50-400mm | Flange Thickness: | 7-28mm |

Web Width: | 50-400mm | Web Thickness: | 5-21mm | Brand Name: | AJ |

Model Number: | HB400 | Color: | Black | shape: | H |

Packaging & Delivery

Packaging Detail: | in bundle with steel wire |

Delivery Detail: | within 15 days after receipt of deposit |

Cheap Price Steel H Beam for Building Advantages

Steel H beam is more flexible in use and save more material than traditional I beam.

Steel H beams are widely used in the construction industry and are available in a variety of standard sizes.

H steel beam may be used both as beams and as columns.It may be used both on their own, or acting compositely with another material, typically concrete.

H shape steel beam has wider flanger than normal I beam,more stable to use.

The construction time of steel h beam will be twice or more faster than use concrete.

Cheap Price Steel H Beam for Building Specifications

Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m | Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m |

| 150*100 | 6 | 9 | 21.4 | 506*201 | 19 | 103.1 | |

| 200*150 | 6 | 9 | 31.2 | 600*200 | 10 | 15 | 95.2 |

| 250*175 | 7 | 11 | 44.1 | 11 | 17 | 106.1 | |

| 300*200 | 8 | 12 | 57.3 | 12 | 20 | 120.3 | |

| 350*250 | 9 | 14 | 79.7 | 700*300 | 13 | 20 | 166 |

| 400*300 | 10 | 16 | 107.3 | 13 | 24 | 185 | |

| 450*300 | 11 | 18 | 124 | 800*300 | 14 | 22 | 191 |

| 500*300 | 11 | 15 | 115 | 14 | 26 | 210 | |

| 11 | 18 | 129.1 | 900*300 | 16 | 28 | 243 |

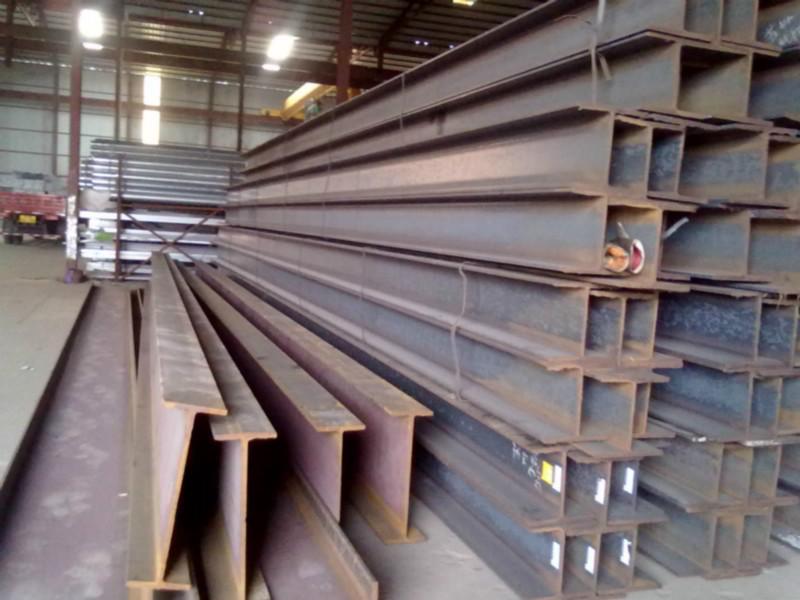

Cheap Price Steel H Beam for Building Pictures

- Q: How do Steel H-Beams contribute to the overall natural disaster resilience of a structure?

- Steel H-Beams play a crucial role in enhancing the overall natural disaster resilience of a structure. These beams are specifically designed to provide strength, stability, and flexibility, making them an ideal choice for withstanding extreme forces and impacts. Here are a few ways in which steel H-beams contribute to the overall natural disaster resilience of a structure: 1. Structural Stability: Steel H-beams offer exceptional structural stability, making them highly resistant to the forces exerted by natural disasters such as earthquakes, hurricanes, and high winds. Their robust design ensures that the structure remains intact even under extreme conditions, reducing the risk of collapse and potential harm to occupants. 2. Load-Bearing Capacity: H-beams have a high load-bearing capacity, allowing them to support heavy loads and distribute the weight effectively throughout the structure. This feature is crucial during natural disasters, where the structure may experience additional loads due to strong winds, heavy rainfall, or debris impact. The ability of steel H-beams to withstand these loads enhances the overall resilience of the structure. 3. Flexibility and Ductility: Steel H-beams possess excellent flexibility and ductility, enabling them to absorb and dissipate energy during seismic events or strong winds. This flexibility prevents the structure from becoming rigid and brittle, which can lead to failure. The ability of H-beams to flex and sway helps in dissipating the forces imposed by natural disasters, reducing the risk of structural damage. 4. Fire Resistance: Steel H-beams have inherent fire-resistant properties, which is crucial for natural disaster resilience. In the event of a fire caused by a disaster, steel beams do not combust or contribute to the spread of flames. This fire resistance allows occupants more time to evacuate safely and minimizes the risk of structural failure due to fire. 5. Longevity and Durability: Steel H-beams are highly durable and resistant to corrosion, ensuring their longevity and structural integrity even in harsh environmental conditions. This durability is vital for the long-term resilience of a structure against natural disasters, as it minimizes the need for regular repairs and replacements. In summary, steel H-beams significantly contribute to the overall natural disaster resilience of a structure by providing structural stability, load-bearing capacity, flexibility, fire resistance, and durability. Their ability to withstand extreme forces and impacts enhances the safety of occupants and reduces the risk of structural failure during natural disasters.

- Q: What are the different types of steel H-beam connections used in healthcare facilities?

- In healthcare facilities, various types of steel H-beam connections are commonly used to ensure the structural integrity and safety of the building. These connections not only provide support but also help in withstanding the dynamic loads and vibrations associated with healthcare operations. Some of the different types of steel H-beam connections used in healthcare facilities include: 1. Welded connections: This is the most common type of connection used in healthcare facilities. It involves welding the steel H-beams together, creating a strong and rigid connection. Welded connections are often used in areas where high load-bearing capacity is required, such as in operating rooms or intensive care units. 2. Bolted connections: Bolted connections involve using bolts and nuts to join the steel H-beams together. This type of connection allows for easier installation, inspection, and maintenance. Bolted connections are commonly used in non-critical areas of healthcare facilities, such as corridors or administrative offices. 3. Moment connections: Moment connections are designed to resist both vertical and horizontal forces. They provide increased stability and rigidity to the structure. These connections are often used in areas where the building is subjected to lateral loads, such as in emergency departments or MRI rooms. 4. Shear connections: Shear connections are primarily used to transfer lateral loads between steel H-beams. They are designed to resist shear forces and prevent the beams from sliding or separating. Shear connections are typically used in areas where the building is subjected to wind or seismic loads, such as in outpatient clinics or radiology departments. 5. Pinned connections: Pinned connections allow for rotation between the steel H-beams. These connections are commonly used in areas where structural movements or deflections are expected, such as in rehabilitation centers or physical therapy rooms. Pinned connections provide flexibility and allow the structure to accommodate loads and movements without excessive stress. It is important to note that the selection of steel H-beam connections in healthcare facilities depends on factors such as the specific building requirements, load conditions, and local building codes. Consulting with structural engineers and architects during the design and construction process ensures the appropriate selection and installation of the most suitable connections for healthcare facility structures.

- Q: Can steel H-beams be used in swimming pool structures?

- Yes, steel H-beams can be used in swimming pool structures. They are commonly used as structural support elements due to their high strength and durability. Additionally, steel H-beams can withstand the corrosive environment of a swimming pool, making them a suitable choice for such structures.

- Q: What are the structural integrity considerations for steel H-beams?

- When it comes to assessing the structural integrity of steel H-beams, there are several important factors that need to be taken into consideration. These factors ensure that the H-beams can effectively withstand different types of loads and maintain their stability over time. Firstly, the load capacity of the H-beams is a primary concern. The structural engineer must calculate and determine the maximum load that the beams can bear without experiencing any deformation or failure. This involves analyzing the yield strength and ultimate tensile strength of the steel, as well as the specific design of the H-beam. Another crucial consideration is the resistance to buckling. H-beams are prone to sudden lateral deflection or bending under compressive forces. To prevent buckling, the beams are designed with appropriate flange thickness, web depth, and spacing between the flanges. These factors contribute to the overall stiffness and rigidity of the H-beam. The strength of the connections between H-beams and other structural components, such as columns or other beams, is also vital for maintaining the overall structural integrity. These connections must be designed in a way that efficiently transfers loads and ensures that the H-beams do not detach or separate under various forces like tension, compression, or shear. Furthermore, fatigue resistance is a significant consideration for H-beams. They are often subjected to cyclic loading, which can lead to fatigue failure over time. To enhance their resistance to fatigue, the beams are typically designed with smooth transitions and rounded edges to reduce stress concentrations. Additionally, proper welding techniques and high-quality materials are used to minimize the risk of fatigue cracks. Lastly, fire resistance is an essential consideration as steel H-beams can rapidly lose their strength under high temperatures. Therefore, fire protection measures such as fireproof coatings or encasements are often necessary to maintain the beams' structural integrity during a fire. These measures delay the temperature rise of the steel and prevent premature buckling or collapse of the beams. In summary, when assessing the structural integrity of steel H-beams, it is crucial to consider their load capacity, resistance to buckling, connection strength, fatigue resistance, and fire resistance. By addressing these factors, engineers can design H-beams that offer durable and reliable support in a variety of construction applications.

- Q: Are steel H-beams suitable for coastal areas with high salt content in the air?

- Steel H-beams are generally suitable for coastal areas with high salt content in the air. However, they may be more prone to corrosion due to the presence of salt. To ensure their longevity, it is important to use corrosion-resistant coatings or materials, perform regular maintenance, and consider the specific environmental conditions of the coastal area.

- Q: What are the different protective coatings available for steel H-beams?

- Steel H-beams have a variety of protective coatings available to enhance durability and prevent corrosion. These coatings are designed to withstand different environmental conditions and offer long-lasting protection. Some commonly used coatings for steel H-beams include: 1. Galvanizing: A widely used coating that involves applying a layer of zinc to create a protective barrier against rust, corrosion, moisture, chemicals, and abrasion. 2. Epoxy Coatings: These coatings provide high-level protection against chemicals, moisture, and UV rays. They are resistant to abrasion and can be applied in different thicknesses based on protection needs. Epoxy coatings are commonly used in industries like oil and gas, marine, and construction. 3. Powder Coating: This dry finishing process applies a layer of powdered resin onto the steel surface. After heating, the powder melts to form a protective layer. Powder coating offers excellent resistance to corrosion, chemicals, and UV rays. It also provides a wide range of color options, making it popular for architectural applications. 4. Paint: Applying a high-quality industrial paint acts as a barrier against moisture, chemicals, and UV rays. It is essential to use paint specifically formulated for steel and apply multiple coats for sufficient protection. 5. Metalizing: This process involves applying a layer of molten metal, like zinc or aluminum, to the steel surface. Metalizing provides excellent corrosion protection and can be applied in different thicknesses depending on the desired level of protection. It is commonly used in harsh environments such as marine and offshore applications. When selecting a protective coating for steel H-beams, factors like intended use, environmental conditions, and budget should be considered. Consulting with a professional or coating specialist can help determine the most suitable coating for specific requirements, ensuring optimal protection and longevity for the steel H-beams.

- Q: Can steel H-beams be fire-resistant?

- Yes, steel H-beams can be made fire-resistant through various methods such as applying fire-resistant coatings, enclosing them in fire-rated materials, or using fire-resistant construction techniques. These measures help to prevent or slow down the spread of fire and maintain the structural integrity of the H-beams during a fire event.

- Q: Can steel H-beams be used in airport hangar construction?

- Yes, steel H-beams can be used in airport hangar construction. Steel H-beams are commonly used in the construction industry due to their strength, durability, and versatility. They can withstand heavy loads and provide excellent support for large structures like airport hangars. The H shape of these beams allows for increased strength and stability, making them ideal for constructing wide-span buildings such as hangars. Additionally, steel is a preferred material for hangar construction as it is resistant to fire, pests, and rot, ensuring the safety and longevity of the structure. Therefore, steel H-beams are a suitable choice for airport hangar construction.

- Q: How do steel H-beams compare to timber beams in terms of sustainability?

- Steel H-beams and timber beams differ significantly in terms of sustainability. Steel H-beams are typically made from recycled steel, which reduces the demand for new steel production and minimizes the carbon footprint associated with manufacturing. Additionally, steel is a highly durable material, meaning that steel H-beams have a longer lifespan and require fewer replacements over time. This durability results in less waste generation and lower maintenance costs, making steel H-beams a more sustainable option in the long run. On the other hand, timber beams have their own sustainability advantages. Timber is a renewable resource, as trees can be replanted to replace those that are harvested. The production of timber beams also requires less energy compared to steel H-beams. Furthermore, the process of harvesting and manufacturing timber has a lower carbon footprint compared to steel production, as it produces fewer greenhouse gas emissions. However, timber beams have limitations in terms of durability and resistance to fire and moisture. They are prone to decay, insect damage, and warping, which can decrease their lifespan and increase maintenance and replacement needs. Additionally, the use of timber from unsustainable logging practices can contribute to deforestation and habitat destruction. In summary, while both steel H-beams and timber beams have sustainability benefits, steel H-beams have the advantage of being made from recycled materials, offering high durability, and reducing waste generation. Timber beams, on the other hand, are renewable, require less energy in production, and have a lower carbon footprint. Ultimately, the choice between steel H-beams and timber beams should consider factors such as the specific application, local availability of materials, and the overall environmental impact throughout the life cycle of the beams.

- Q: Are steel H-beams suitable for use in the construction of sports stadiums or arenas?

- Yes, steel H-beams are commonly used in the construction of sports stadiums and arenas due to their structural strength, versatility, and ability to support large loads.

Send your message to us

Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords