Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Flat Bar Hot Rolled Retangular Section Description:

Steel flat bar hot rolled retangular section is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel flat bar hot rolled retangular section is usually made of structural steel and is used in construction and civil engineering. The steel flat bar hot rolled retangular section resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel flat bar hot rolled retangular section theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Flat Bar Hot Rolled Retangular Section:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

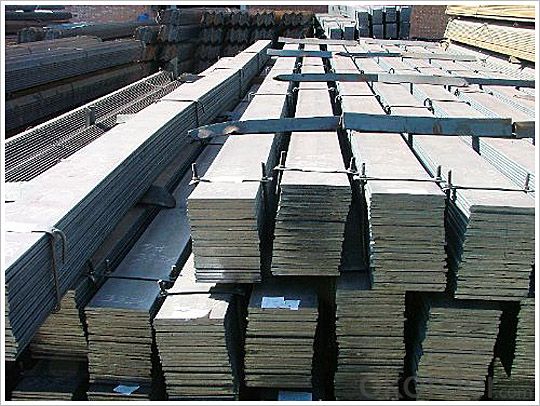

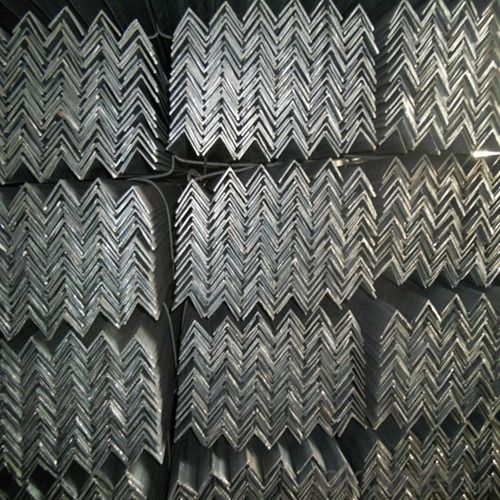

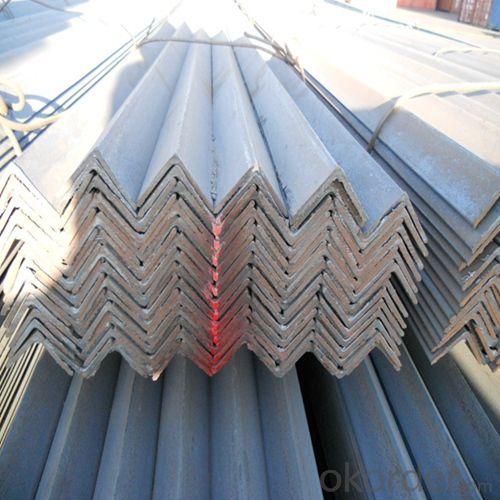

3. Steel Flat Bar Hot Rolled Retangular Section Images:

4. Steel Flat Bar Hot Rolled Retangular Section Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What is the rolling range of the micro cold rolled flat steel production line?

- The pig iron used for steelmaking is smelted in a steel furnace and smelted by a certain process, and then steel is obtained. Steel products are steel ingot, continuous casting billet and direct casting of various steel castings. Generally speaking, steel is generally used to make steel made of various kinds of steel. Steel belongs to ferrous metals, but steel is not exactly black metal.

- Q: Are steel flat bars suitable for making conveyor systems?

- Yes, steel flat bars are suitable for making conveyor systems. Steel flat bars are known for their strength, durability, and ability to withstand heavy loads, which are essential qualities for conveyor systems. They provide a sturdy and stable base for conveying materials and can handle the continuous motion and impact that conveyor systems require. Additionally, steel flat bars can be easily fabricated and customized to the specific size and shape required for the conveyor system. Overall, steel flat bars are a reliable and commonly used material for constructing conveyor systems in various industries.

- Q: How do steel flat bars contribute to the overall stability of structures?

- There are various ways in which steel flat bars contribute to the overall stability of structures. To begin with, they offer structural support and reinforcement, assisting in the distribution and transfer of loads. Their flat shape allows for easy attachment to other structural components like beams and columns, thereby increasing the strength and stability of the structure. Moreover, steel flat bars possess high tensile strength, making them resistant to bending and breaking under heavy loads or external forces. This strength enables them to effectively resist deformation and maintain the structural integrity of the building. Steel flat bars also play a critical role in preventing lateral movement and buckling. By strategically placing and connecting them to other structural elements, they help resist horizontal forces such as wind or seismic loads, ensuring the stability and safety of the structure during extreme events. Additionally, steel flat bars can function as bracing elements, providing added stiffness to the structure. By installing them diagonally or horizontally, they enhance the overall rigidity of the building, reducing the potential for excessive deflection or sway. Furthermore, steel flat bars possess excellent durability and corrosion resistance properties. This ensures their ability to withstand harsh environmental conditions, including moisture and temperature fluctuations, without compromising their strength or stability. Their longevity contributes to the overall stability and durability of the structure. To summarize, steel flat bars contribute to the overall stability of structures by offering structural support, distributing and transferring loads, resisting deformation and lateral movement, enhancing rigidity, and providing durability and corrosion resistance. Their versatility and strength make them an essential component in various construction applications, ensuring the safety and stability of buildings and infrastructure.

- Q: How do steel flat bars perform in terms of noise reduction?

- Steel flat bars are not specifically designed for noise reduction. They primarily serve as structural components in construction projects.

- Q: Can steel flat bars be used for manufacturing agricultural machinery?

- Agricultural machinery manufacturing can indeed utilize steel flat bars. Steel, being a versatile and robust material, finds widespread application across multiple industries, including agriculture. Steel flat bars possess several advantages, such as high strength, durability, and resistance to corrosion, which render them suitable for agricultural machinery. They can be utilized in the fabrication of equipment like plows, harrows, cultivators, and seeders, providing the essential structural support and stability required. Moreover, steel flat bars lend themselves easily to welding, bending, and forming into varied shapes, enabling customization and efficient production of agricultural machinery. In summary, the strength, durability, and versatility of steel flat bars make them a dependable and cost-effective option for agricultural machinery manufacturing.

- Q: Are steel flat bars available in different finishes?

- Yes, steel flat bars are available in different finishes. Common finishes include hot rolled, cold rolled, galvanized, and polished.

- Q: What are the advantages of using steel flat bars?

- There are several advantages of using steel flat bars. Firstly, steel is a highly durable and strong material, making flat bars made from steel ideal for load-bearing and structural applications. Additionally, steel flat bars are resistant to corrosion, which improves their longevity and makes them suitable for outdoor use. Steel flat bars also offer excellent versatility and can be easily fabricated into various shapes and sizes, allowing for flexibility in design and construction projects. Moreover, steel flat bars have a high strength-to-weight ratio, making them lighter than other materials of similar strength, resulting in easier handling and transportation. Lastly, steel is a sustainable and recyclable material, aligning with environmental considerations and promoting sustainability in construction and manufacturing industries.

- Q: How do steel flat bars compare to fiberglass flat bars?

- Steel flat bars are known for their strength and durability, making them suitable for heavy-duty applications. They offer excellent load-bearing capabilities and are resistant to bending or warping under pressure. On the other hand, fiberglass flat bars have the advantage of being lightweight and corrosion-resistant. They are often used in applications where weight is a concern or where exposure to chemicals or moisture is a factor. Ultimately, the choice between steel and fiberglass flat bars depends on the specific requirements of the project and the desired properties of the material.

- Q: What are the different finishes available for steel flat bars?

- There are several different finishes available for steel flat bars, each offering unique characteristics and appearances. Some common finishes include: 1. Hot Rolled: This is the most basic finish, achieved through the process of heating steel above its recrystallization temperature and allowing it to cool. It results in a rough and scaled surface texture. 2. Cold Rolled: This finish is achieved by passing the steel flat bar through a series of rollers at room temperature, resulting in a smooth and clean surface texture. Cold rolling also improves the dimensional accuracy and strength of the flat bar. 3. Galvanized: Galvanizing involves applying a protective coating of zinc to the steel flat bar, which helps prevent corrosion and increases its longevity. This finish is commonly used in outdoor and corrosive environments. 4. Painted or Powder Coated: These finishes involve applying a layer of paint or powder to the steel flat bar, providing both aesthetic appeal and protection against corrosion. The choice of color allows for customization and matching with other elements in a design. 5. Stainless Steel: Stainless steel flat bars come in various finishes, including brushed, mirror, satin, and mill. These finishes offer different levels of shine and smoothness and are chosen based on aesthetic preferences and specific applications. 6. Blackened or Blued: These finishes involve chemically treating the surface of the steel flat bar to create a black or blue oxide layer, which provides a unique and decorative appearance. These finishes are often used in architectural and artistic applications. Each finish has its own advantages and is selected based on the desired appearance, durability, and application of the steel flat bar. It is important to consider the specific requirements and conditions of a project before choosing the appropriate finish.

- Q: What is the weight of a standard steel flat bar?

- The weight of a standard steel flat bar can vary depending on its dimensions and the specific type of steel used. However, in general, the weight of a standard steel flat bar can be calculated by multiplying the density of steel (usually around 7850 kg/m³) by the cross-sectional area of the bar, which is determined by its width and thickness. The formula to calculate the weight of a steel flat bar is: Weight (kg) = Width (mm) x Thickness (mm) x Length (m) x Density (kg/m³). By using this formula, one can determine the weight of a specific steel flat bar based on its dimensions.

Send your message to us

Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords