Stainless Steel Sheet With Price In Different Grades

- Loading Port:

- Tianjin

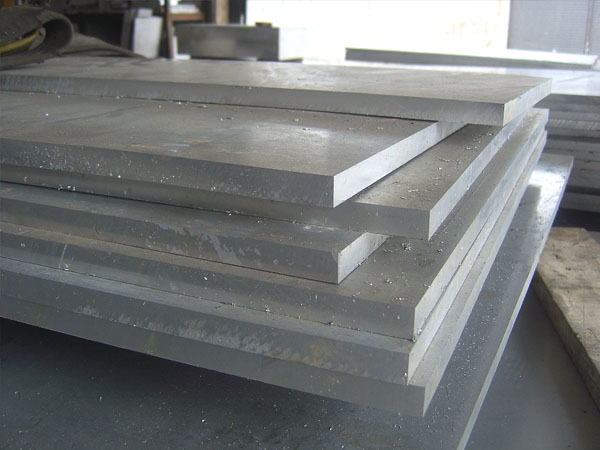

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

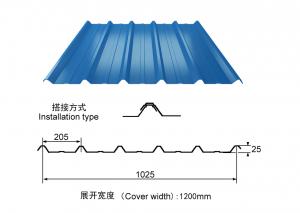

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What are the common sizes of stainless steel sheets?

- Common sizes of stainless steel sheets vary depending on the industry and application. However, there are some standard sizes that are readily available in the market. For instance, stainless steel sheets commonly come in thicknesses ranging from 0.4mm to 3.0mm. The most common widths are 1000mm, 1219mm, and 1500mm, while the most common lengths are 2000mm, 2438mm, and 3000mm. These dimensions are often referred to as 4x8 (4 feet by 8 feet), as they are the standard size for stainless steel sheets used in various construction and fabrication projects. It's worth noting that stainless steel sheets can also be custom-cut to specific dimensions based on the requirements of a particular project. This allows for greater flexibility and ensures that the sheets fit perfectly for the intended application.

- Q: Can stainless steel sheets be used in high-temperature applications?

- Indeed, high-temperature applications can utilize stainless steel sheets. Renowned for its superb heat resistance characteristics, stainless steel proves itself adaptable in environments boasting elevated temperatures. Notably, it boasts a formidable melting point, ensuring its durability and structural integrity endure even under extreme conditions. Furthermore, stainless steel showcases commendable oxidation resistance, thwarting scale formation and preserving its surface's sleekness. Consequently, stainless steel sheets rank favorably when considering their widespread employment in diverse high-temperature settings, encompassing heat exchangers, furnaces, boilers, and exhaust systems.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Yes, stainless steel sheets can be used for outdoor furniture. Stainless steel is a highly durable material that is resistant to rust, corrosion, and weathering. This makes it an ideal choice for outdoor furniture as it can withstand the elements and retain its appearance and structural integrity over time. Additionally, stainless steel has a sleek and modern look that can complement various outdoor design styles. Whether it's for tables, chairs, or other outdoor furniture pieces, stainless steel sheets can provide a long-lasting and visually appealing option for outdoor use.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to the presence of chromium, which forms a protective layer on the surface of the material. This layer, known as chromium oxide, acts as a barrier against moisture, oxygen, and other corrosive substances, preventing them from reaching the underlying steel and causing corrosion.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304 material and 304J1 contain nickel different, 304J1 contain 6 nickel, 304 contain 8 nickel

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: Are stainless steel sheets suitable for water treatment applications?

- Water treatment applications can greatly benefit from the use of stainless steel sheets. The reason for this is that stainless steel has exceptional resistance to corrosion, making it the perfect material for environments where there is a presence of water and moisture. It is able to withstand rust, staining, and pitting, guaranteeing the sheets' longevity and durability in water treatment facilities. Moreover, stainless steel sheets possess hygienic qualities. They are effortless to clean and maintain, which is especially crucial in water treatment applications where cleanliness and sanitation are of the utmost importance. Additionally, stainless steel does not react with water, meaning it does not release harmful substances into the water being treated. In addition to these benefits, stainless steel sheets exhibit strength and can tolerate high pressures and temperatures. This is highly significant in water treatment processes that involve filtration, disinfection, and other treatment methods that may require rigorous conditions. To conclude, stainless steel sheets are an outstanding option for water treatment applications due to their resistance to corrosion, hygienic properties, strength, and durability. They present a dependable and long-lasting solution for various components in water treatment facilities, including tanks, pipes, valves, and other equipment.

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

- Q: How do you prevent intergranular corrosion in stainless steel sheets?

- Intergranular corrosion in stainless steel sheets can be prevented through various methods such as proper selection of stainless steel grade, heat treatment, and appropriate welding techniques. 1. Stainless Steel Grade Selection: Choosing the right stainless steel grade is crucial in preventing intergranular corrosion. Grades with a low carbon content, such as 304L or 316L, are less susceptible to intergranular corrosion compared to higher carbon grades. These low carbon grades minimize the formation of chromium carbide precipitates, which are the main cause of intergranular corrosion. 2. Heat Treatment: Heat treatment processes like solution annealing and quenching can help eliminate or reduce the formation of chromium carbide precipitates. This treatment restores the stainless steel's corrosion resistance by dissolving existing precipitates and promoting the formation of a protective chromium oxide layer on the surface. 3. Welding Techniques: Careful attention must be given to welding stainless steel sheets to prevent intergranular corrosion. Processes like gas tungsten arc welding (GTAW) or laser welding that provide precise control over heat input are preferred. Additionally, using low carbon filler metals or consumables specifically designed for intergranular corrosion resistance can minimize the risk of corrosion. 4. Post-Weld Cleaning and Passivation: After welding, it is essential to thoroughly clean the welded area to remove any contaminants or oxide scales that could promote corrosion. Acid cleaning followed by passivation helps restore the protective oxide layer and enhances the stainless steel's resistance to intergranular corrosion. 5. Avoiding Sensitization: Sensitization occurs when stainless steel is exposed to high temperatures for extended periods, leading to the formation of chromium carbide precipitates. It is crucial to avoid prolonged exposure to temperatures between 450-850°C (842-1562°F) during fabrication or service to prevent sensitization and subsequent intergranular corrosion. By implementing these preventive measures, intergranular corrosion in stainless steel sheets can be effectively minimized, ensuring the longevity and performance of the material in various applications.

- Q: Are stainless steel sheets suitable for architectural panels?

- Yes, stainless steel sheets are highly suitable for architectural panels due to their durability, corrosion resistance, and aesthetic appeal. They provide a sleek and modern look, making them a popular choice for contemporary architectural designs. Additionally, stainless steel sheets can be customized in various finishes and patterns, allowing for creative and versatile architectural applications.

Send your message to us

Stainless Steel Sheet With Price In Different Grades

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords