Stainless Steel Coil Rolled Hot Rolled With Best Price

- Loading Port:

- Shanghai

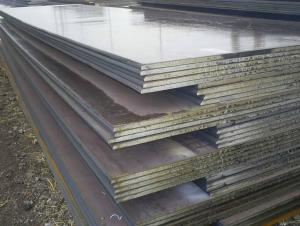

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled Stainless sheet is widely used in the construction field and decoration field, etc. There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. gr are as follows: 201, 202, 301, 304, 316,430, etc.

The suace is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally itaround 3 tons/each size.

How many tons did you export in one year?

---Normally it 9000 tons totally.

Where is your client from?

---Normally it is?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What is the difference between brushed and polished stainless steel sheets?

- The main difference between brushed and polished stainless steel sheets lies in their surface finish. Brushed stainless steel sheets have a textured, linear pattern created by brushing the surface with abrasive materials, giving it a matte appearance. On the other hand, polished stainless steel sheets have a smooth, reflective surface achieved by polishing the steel with a fine abrasive compound.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- It's 0.08mm stainless steel!! It's so thin. It's expensive. A kilo is at least 10 yuan!!

- Q: Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is highly resistant to corrosion, making it an ideal material for outdoor applications. It can withstand exposure to various weather conditions, including rain, humidity, and sunlight, without rusting or deteriorating. Additionally, stainless steel's strength and durability ensure that it can withstand the pressure and weight typically exerted on railings, making it a reliable choice for outdoor installations.

- Q: How do you prevent distortion when welding stainless steel sheets?

- To prevent distortion when welding stainless steel sheets, one must ensure proper heat control and minimize the amount of heat input. This can be achieved by using a lower welding current and speed, employing a proper welding technique, and utilizing preheating or post-welding heat treatment methods if necessary. Additionally, using clamps or fixtures to hold the sheets in place during welding and distributing the heat evenly across the joint can also help prevent distortion.

- Q: Why do galvanized and stainless steel sheets buy more expensive than thin ones?

- Galvanized sheet refers to the surface coated with a layer of zinc steel plate. Zinc plating is an economical and effective method of corrosion protection, and about half of the world's zinc production is used in this process.

- Q: Are stainless steel sheets resistant to fire?

- Stainless steel sheets possess a remarkable ability to withstand fire. This is due to the fact that stainless steel is a type of metal alloy that contains a significant amount of chromium. When exposed to air or moisture, chromium forms a protective layer of chromium oxide on the surface. This layer acts as a barrier, preventing oxygen from reaching the underlying metal. As a result, stainless steel is highly resistant to corrosion and fire. Stainless steel sheets have an impressive melting point of approximately 2750°F (1510°C). This temperature is considerably higher than what is typically encountered in most fire situations. Consequently, stainless steel can endure intense heat for an extended period without losing its shape or structural integrity. Additionally, stainless steel is non-combustible and does not contribute to the spread of flames. It does not emit harmful gases or toxic fumes when exposed to fire. Therefore, stainless steel is a safe material for various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Given these characteristics, stainless steel sheets are extensively used in structures with fire ratings, including fire doors, fire-rated walls, and fire-resistant enclosures. They serve as effective barriers against heat and flames, containing the fire and safeguarding the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may undergo some level of distortion or damage. Hence, it is essential to consider the specific fire rating requirements and seek advice from experts to ensure the proper selection and installation of stainless steel sheets in fire-resistant applications.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, it is important to regularly clean and maintain them. Use a soft cloth or sponge along with mild soap or a stainless steel cleaner to remove any dirt or grime. Avoid using abrasive cleaners or scrubbing pads, as they can scratch the surface. Additionally, be cautious of exposing stainless steel sheets to harsh chemicals or acidic substances, as they can cause discoloration.

- Q: Can stainless steel sheets be used for decorative ceiling tiles?

- Yes, stainless steel sheets can indeed be used for decorative ceiling tiles. Stainless steel is a versatile material that offers a modern and sleek appearance, making it a popular choice for decorative purposes. Its durability, resistance to corrosion, and ability to withstand high temperatures also make it suitable for ceiling applications. Additionally, stainless steel sheets can be easily customized with various finishes, patterns, and designs to create unique and visually appealing ceiling tiles.

- Q: How do you determine the weight of a stainless steel sheet?

- To determine the weight of a stainless steel sheet, you need to consider its dimensions, thickness, and density. The first step is to measure the length, width, and thickness of the sheet using a measuring tool such as a ruler or caliper. Make sure to measure in the same unit of measurement, such as inches or millimeters, to ensure accuracy. Next, you need to determine the density of stainless steel. Stainless steel has a density of around 7.9 grams per cubic centimeter (g/cm³) or 7900 kilograms per cubic meter (kg/m³). This value may vary slightly depending on the specific grade or alloy of stainless steel being used. Once you have the dimensions and density, you can calculate the weight using the formula: weight = volume × density. To find the volume, multiply the length by the width and the thickness. For example, if you have a stainless steel sheet that measures 1 meter by 1 meter and has a thickness of 2 millimeters, the volume would be 0.001 cubic meters (1m x 1m x 0.002m). Using the density of stainless steel (7900 kg/m³), you can then calculate the weight by multiplying the volume by the density. In this example, the weight of the stainless steel sheet would be 7.9 kilograms (0.001m³ x 7900 kg/m³). It is important to note that this calculation will provide an approximate weight as it assumes a uniform thickness throughout the entire sheet. Additionally, variations in composition or manufacturing processes may lead to slight deviations in the density of the stainless steel, which can affect the accuracy of the weight calculation.

- Q: Can stainless steel sheets be used for water tanks or storage containers?

- Certainly, water tanks or storage containers can be made using stainless steel sheets. This material is widely chosen for these purposes because of its remarkable resistance to corrosion and durability. Its ability to resist rust and corrosion makes it perfect for storing water or other liquids. Moreover, stainless steel is hygienic and effortless to clean, which is vital for preserving the purity of stored water or food items. Furthermore, stainless steel sheets can be easily shaped and sized to meet the specific needs of the water tank or storage container. All in all, stainless steel sheets are a dependable and enduring choice for water tanks or storage containers.

Send your message to us

Stainless Steel Coil Rolled Hot Rolled With Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords