Spiral Paper Tube Winding Machine with high quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

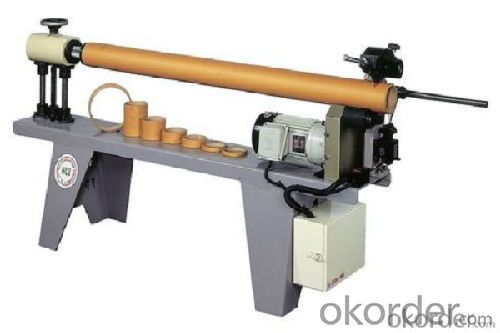

Hot Sell Spiral Paper Tube Winding Machine

2.Main Features

Condition: New

Product Type: Paper Core Machine

Processing Type: Winding Machine

Place of Origin: China (Mainland)

Voltage: 3*380 V

Power(W): 15 KW

Dimension(L*W*H): 5500*2000*2000 mm

Weight: 4000 KG

Certification: CCIS

Warranty: 1 year

3. Images

4. Specifications

Hot Sell Spiral Paper Tube Winding Machine Technical Parameter

Technical Parameter | Control system | |||

Number of roller | 3-16 layer | PLC controller | Delta DVP14SS2 | |

Tube diameter | 20-200 mm | Touch screen | MCGS TPC7062 | |

Tube wall-thickness | 1-10 mm | Transducer | YASKAWA 7.5 KW | |

Core mould fixed way | Flank chuck | Electric part | Schneider | |

Winding head | 4 | Single part | Omron | |

Cutting way | Round knife | Pneumatic part | AIRTAC | |

Gluing way | Single / double sides | Fix length way | Optoelectronic switch/encode | |

Operator | 1-2 person | Equip device | ||

Winding speed | 3-30 m/min | Paper shelf type | Integral reel stand | |

Speed control | Transducer | Auto fall tube shelf | Have | |

Driving system | Glue shelf | Have | ||

Main motor | 7.5 KW | Belts | 4 | |

Reducer type | WPO155 JIACHENG | Core mould | 2 | |

Cutting motor | Stepper motor | Cut up-down control | Y lead screw+ stepper motor | |

Glue pump | 1.5 KW | Cut left-right control | Z lead screw+ servo motor | |

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It's a good mechanical design problem! In principle, yes, for example, to achieve the rated torque of the motor. He'll stop by himself! What isn't that great torque? You can zoom in on the load torque

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: Working principle of packing machine

- Then, by heating the sealing part of the bag bottom sealing, again is material, the material into the packaging machine, and then sealing, finally cut off, a complete package came out, this is the working principle of small vertical packaging machine.

- Q: What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

Send your message to us

Spiral Paper Tube Winding Machine with high quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords