Solid White PVC Foam Board/Furniture Board - PVC Ceiling Panel Price in India

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction

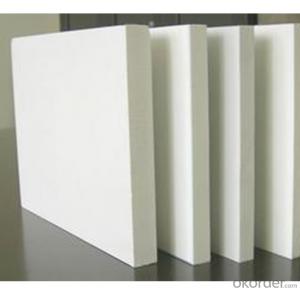

PVC foam board is made from polyvinyl chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anti-corrosive metabolism and recyclable,moisture resistant,lightweight.

2. Features

(1).Environmental and non-toxic material

(2).Waterproof and fireproof

(3).Easy maintenance

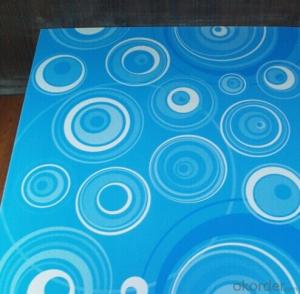

(4).Kinds of sizes, attractive appearance, reasonable price

(5).Impact Resistant

(6).Light in weight and easy to install can save a lot of time and man power cost.

3. Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layered other industry.

4.Detailed parameter list

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

7 | Executive standard | QB/T 2463.1-1999 |

8 | Certificate | SGS |

5.Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

6. FAQ

(1). Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

(2). Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

(3). Which Payment Terms?

Ali Trade Assurance, T/T(Telegraphic Transfer), West Union, L/C etc.

(4). Lead Time: How soon we can get the shipment?

Usually, it's within 7-15 working days after receiving payment.

7.Advantages

1. we have our owned PVC foam sheet factory located , China's most popular pvc sheet production area, which make sure the production ability and products high quality.

2. our office located in Beijing , the capital of china , it makes us to keep in touch with buyers timely and very convenient for business talking in our office

3. our overall different department makes us the high standard of working efficiency. such as our solid financial department, sales department, documents department and logistic department .

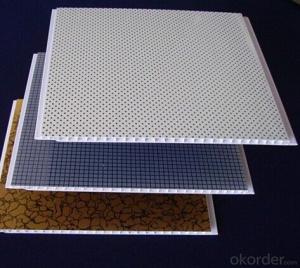

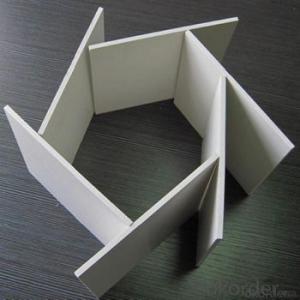

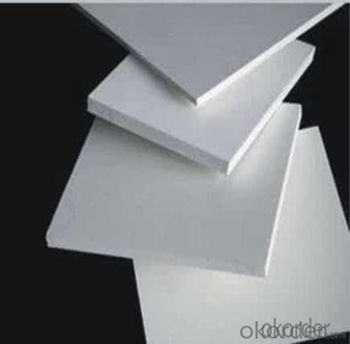

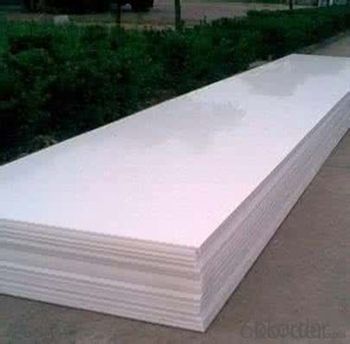

8. Pictures

- Q: Pvc buckle board ye demolition?

- Long strip pvc buckle plate is so demolished: First of all, look at the installation when the pvc board and repair corners have not hit the glass glue, if the fight, it cut it with an industrial knife. And then put the word screwdriver or utility knife inserted in the last piece and the penultimate gap, gently swing up and down, while the last piece of pvc board is loose, then the board to the left or right side of the corner Push, there will be one side down, and then grabbed the side with both hands, gently down a pressure, slightly with the point of force, a pull, came out. And then dismantling the inside of the board, it is necessary a cross screwdriver, and because each piece of pvc board will be on the tapping of the screw, the first under the self-tapping screws, and then slowly demolition, do not break. Finally, open the pipe hole, the first to remove the board according to the direction of the release, (must be according to the direction) Oh, and then need to smoke pipe hole place to mark, and then buy the smoke pipe vertically on the mark, With paint strokes along the smoke pipe draw a circle, and then open the hole hole. Do a good job after the original path installed, surrounded by a good glass glue, on the line.

- Q: My family just moved into a new house in Maryland. In the basement there is a finished part and an unfinished part we use for storage. Over the last few days, we noticed this smell/odor coming from the basement, most notably from the unfinished side. We discovered a large PVC pipe which dead-ends has been leaking this dark brown water, and identified this water as the source of the smell.Does anyone know what this dead-end pipe is for?Thanks a bunch!

- It' must likely your sewage line there around 3to4 in pipe

- Q: How to weld PVC hard board

- Hot plate welding (for flat type parts), it is the use of electric heating metal mold to be connected to the surface of plastic parts of the thermoplastic welding process. Almost suitable for all large or small thermoplastic parts. Particularly suitable for welding less soft semi-crystalline thermoplastics. As the different mold surface temperature can be applied to two different thermoplastic materials, this process is best suited for welding different materials. Hot plate welding can achieve high welding strength. But the cycle of the process may be relatively long, small parts need 15s, and a lot of parts to be a few minutes.

- Q: how to build cat cages out of PVC pipe?

- Have you looked on YouTube?

- Q: My house would like to buy PVC decorative board ceiling but do not know how to buy PVC board how to determine the purchase of PVC board is toxic to ask you prawn support a few strokes Thank you

- PVC easy We produce PVC high-end green pellets for three decades, the landlord said the PVC decorative plate is difficult to judge the naked eye alone. Because this sheet is non-transparent products. At present, most of the buckle boards on the market are lead salts as stabilizers, and lead salts are known for many years ago as non-environmentally friendly raw materials. But there are also a lot of buckle manufacturers use environmentally friendly calcium zinc or organic tin to do heat stabilizer, this kind of relatively environmentally friendly non-toxic. If you really want to use more intuitive way to judge, then the price of some of the total will always be more assured. Because the better the use of raw materials, the higher the cost.to crack, fade, prone to scratches, the price is cheaper

- Q: Production of PVC foam board of raw materials are what ah? What is the role of ah?

- PVC resin: This is the most important raw materials, foam substrate, the production of PVC foam sheet generally use P-700-type PVC resin, the processing of its gelation speed, processing temperature is relatively low, product quality and density Easy to control. In the production of leather foam PVC sheet, in order to improve product quality, strict control of product density and thickness fluctuations, more use of P-700-type vinyl PVC resin. In the production of free foam PVC sheet, from the lower production costs to consider, there are many manufacturers using calcium carbide P-700-type PVC resin

- Q: Engaged in the wedding industry, want to wedding photos (generally 60cm * 90cm or so) of the backplane into a polymer material, and now the backplane is generally made of wood, with crystal to seal the photos on the board, do not know PC board, PP board, PE board, PVC board, ABS board, etc., for which polymer material is good, mainly can not bend, not easy to deformation, hardness slightly higher, as well as consider the cost, which board is more suitable? Seeking

- These have an expansion rate, not suitable for use in the frame, I suggest you use the wood plastic, invariable, super strong, the price depends on your bargaining power, and the other with their own not much, so it does not matter

- Q: What is the proportion of PVC board? Thank you!

- According to the different weight of the process will be different, such as the foam process will be the point of the extrusion process will focus on the floor, but as the words of the floor than other wood ah tile ah what is much lighter

- Q: Hollow engraved high density board and PVC which is good

- Hollow carved flowers

- Q: Pvc foam board what materials?

- 1 PVC foam board, also known as snow Fu board and Andy board, the chemical composition of PVC. Features: 1. Waterproof, flame retardant, acid and alkali, moth, light, heat, noise, shock absorption characteristics; 2. And wood processing the same, and processing performance is far better than wood; 3. is the wood, aluminum, composite plate of the ideal alternative; 4. Leather surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture and so on.

Send your message to us

Solid White PVC Foam Board/Furniture Board - PVC Ceiling Panel Price in India

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords