Geotextil Szeged Slope Geocell (Plastic Slope Geocell)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Slope Geocell:

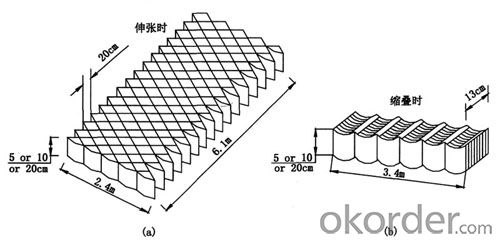

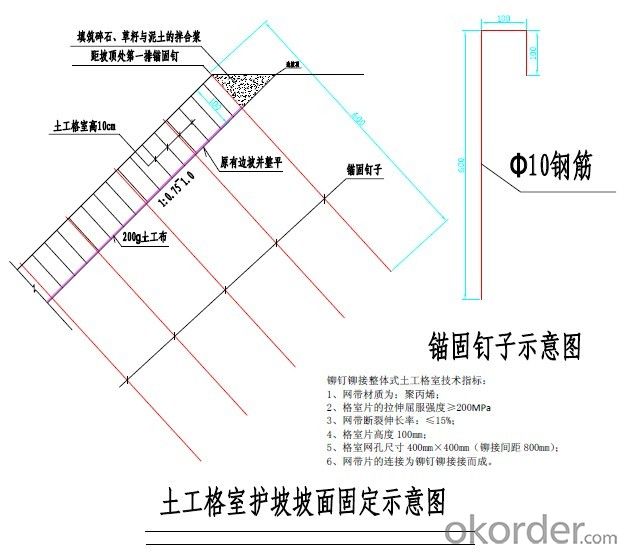

The soil work space room is to be take by the HDPE breadth of the high strength, was become by strong dint welding of have the net space room structure, it flex from such as, the conveyance can fold, usage the hour opens and hurtles to fill the ground, or concrete to anticipate, constituting to have the strong side to limit and greatly just the structure body of the degree. Can use to be the mat layer, handle the loading ability that the weak foundation enlarges the foundation, also can build to constitute the ÆÂ to face the protection structure on the bedcover, can also use to construct to pay file structure etc.

Main Features of Plastic Slope Geocell:

Notes:When you are ready to inquire hdpe geocell,pls indicate your specifications as follows:

1.Geocell Height(50mm to 200mm).

2.Welding Distance(330mm to 1000mm).

3.Seam Peel Strength(1000N/10cm,1200N/10cm,1400N/10cm).

4.HDPE Sheet Thickness(1.1mm,1.2mm,1.5mm,1.75mm).

Specifications of Plastic Slope Geocell:

Technical Data

Art No. | Width(cm) | Length (cm) | Height (mm) |

Welding Interval (mm) | Thickness (mm) | Unit Weight (g/m2) | Peeling Strength at Welding Point ( N/ mm) | Peeling Strength at Connecting ( N/ mm) | Slice Yield Strength ( N/ mpa) |

PLC0301 | 600 | 400 | 50 | 400 | 1 | 550 | 10 | 10 | 18 |

PLC0302 | 600 | 400 | 75 | 400 | 1 | 850 | 10 | 10 | 18 |

PLC0303 | 600 | 400 | 100 | 400 | 1 | 1100 | 10 | 10 | 18 |

PLC0304 | 600 | 400 | 150 | 400 | 1 | 1600 | 10 | 10 | 18 |

PLC0305 | 600 | 400 | 200 | 400 | 1 | 2200 | 10 | 10 | 18 |

Remarks: A breadth of product can press customer to request to create at will, other special specification according to agreement or contract performance. | |||||||||

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Remarks: 1. This is a basic technical specification. 2. All of the technical indexes can be reached according to the customers' demand, and the other special standards will be carried out by agreement or contact.

| ||||||

Applications of Plastic Slope Geocell:

How to make Geocell

Walk into our factory

IMages of Plastic Slope Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q: How do geotextiles affect plant growth?

- Geotextiles can positively impact plant growth by providing a stable environment for roots, preventing soil erosion, and promoting moisture retention. Additionally, they control weed growth, regulate soil temperatures, and enhance nutrient availability, ultimately leading to healthier and more productive plants.

- Q: How do geotextiles help with erosion control in river channels?

- Geotextiles aid in erosion control in river channels by acting as a protective barrier against soil erosion. They are placed along the riverbanks or riverbeds to prevent the loss of soil particles due to water flow. Geotextiles stabilize the soil, increase its resistance to erosion, and promote vegetation growth. Additionally, they allow water to pass through while retaining sediment, thus reducing sedimentation in the river channel.

- Q: Can geotextiles be used for reinforcement of embankments?

- Yes, geotextiles can be used for the reinforcement of embankments. They are commonly used in civil engineering projects to improve the stability, strength, and longevity of embankments. Geotextiles provide separation, filtration, and reinforcement functions, helping to prevent erosion, soil movement, and structural failure.

- Q: Can geotextiles be used in geocomposite drains?

- Yes, geotextiles can be used in geocomposite drains. Geocomposite drains are comprised of multiple layers, including a geotextile layer that helps with filtration and separation. The geotextile layer allows water to flow through while preventing the passage of soil particles, making it an effective component in geocomposite drain systems.

- Q: What are the materials used for spinning geotextiles?

- Geotextile is divided into several, filament spunbond acupuncture non-woven geotextile, this is the name suggests is to use silk to do; staple acupuncture non-woven geotextile, this is the use of fiber to do;

- Q: Nail cave geotextile with a nail where?

- Hardware market can be nails, I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: How do geotextiles affect soil moisture retention?

- Geotextiles can significantly impact soil moisture retention by acting as a barrier between the soil and the external environment. They help in reducing excessive evaporation from the soil surface, thus minimizing water loss. Additionally, geotextiles prevent the erosion of soil particles, maintaining soil structure and facilitating better water infiltration. This ultimately improves soil moisture retention by creating a more favorable and stable environment for plants to grow.

- Q: Geotextile (250g / square meter) offer

- 250 grams of short fiber geotextile Price: 2.30 yuan / square meter 250 grams of filament geotextile Price: 3.70 yuan / square meter 250 grams of impervious geotextile Price: 2.80 yuan / square meter.

- Q: What are the maintenance requirements for geotextiles?

- Geotextiles generally have low maintenance requirements. However, regular inspection and cleaning are important to ensure their optimal performance. The specific maintenance needs may vary depending on the type and application of the geotextile, but in general, it is recommended to remove any debris, sediment, or vegetation that may accumulate on the surface. Additionally, periodic checks for any signs of damage or wear, such as tears or fraying, should be conducted and repairs or replacements should be made as necessary.

Send your message to us

Geotextil Szeged Slope Geocell (Plastic Slope Geocell)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords