Silica Brick Silicon Mullite Composite Wear Resistant Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

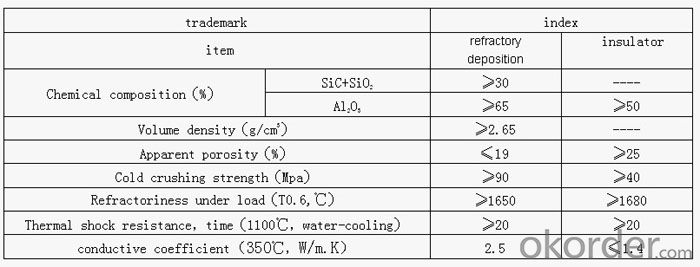

The product is produced by compounding Silicon mullite based working layer with wear resistance and high temperature resistance, and insulating layer by special manufacturing method. And insulating layer still keeps enough strength to resist the damage from mechanical stress. So this product is featured with high crushing strength, high hot strength, good thermal shock resistance, good wear resistance, strong anti-stripping resistance, insulation and energy saving.

Applications:

Transitional zone of rotary kiln in cement and other industries.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: Which material is good for furnace refractory?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 94% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, thermal shock resistance is poor. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

Send your message to us

Silica Brick Silicon Mullite Composite Wear Resistant Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords