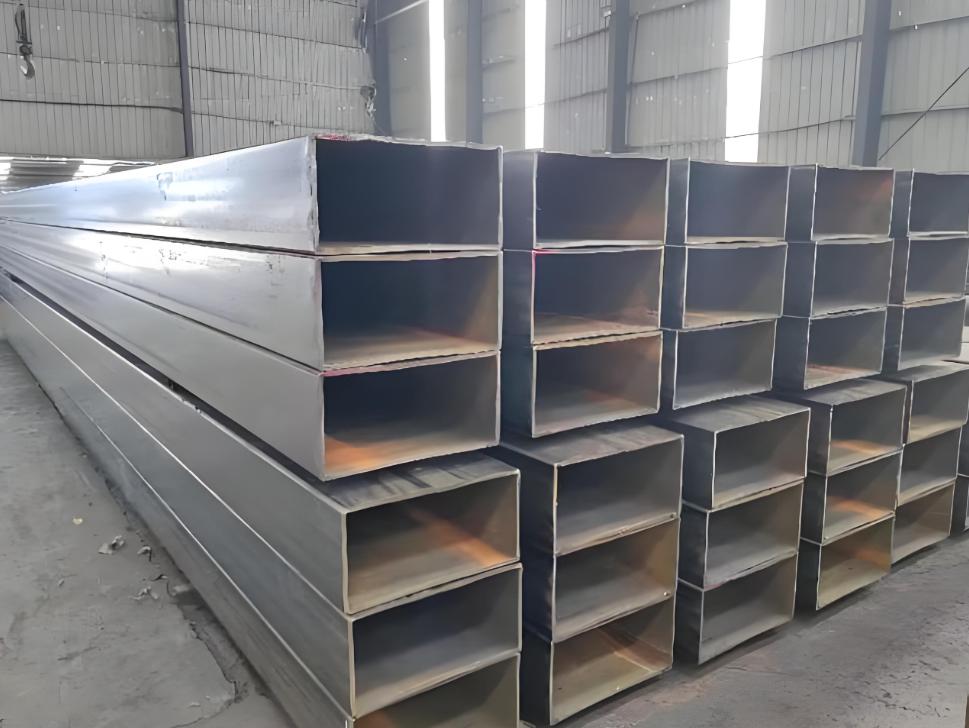

SHS RHS CHS square hollow section rectangular hollow section circular hollow section pipe & tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

GB

Technique:

Cold Rolled,Cold Drawn,ERW,Extruded,Hot Rolled

Shape:

Square,Round,Rectangular,Oval

Surface Treatment:

Galvanized,Black

Steel Grade:

Q195,Q235,Q355

Thickness:

0.15-20mm

Length:

1-12m or customized

Net Weight:

0.625-171.658kg/m

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact rcjs steel.

| Type | cold rolled pre-galvanized welded square/rectangular steel pipe/tube/hollow section prefab house steel pipe |

| Diameter | 10mm-600mm or as customized |

| Wall Thickness | 0.1mm-300mm or as required |

| Length | 2-12m or as request |

| Standard | ASTM A53, BS 1387, BS 1139, BS En10025, etc. |

| Steel Grade | Q195 = S195 / A53 Grade AQ235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2Q345 = S355JR / A500 Grade B Grade C |

| Surface Treatment | Bared, Black Painted, Galvanized, Oiled or to your requirements |

| Technique | Welded |

| Package | Packed in Bundles with Two Nylon Strip. |

| Application | 1. Fluid pipe 2. Power Plant 3. Structure pipe 4. High and low-pressure Boiler tube 5. Seamless pipe /tube for petroleum cracking 6. Conduit pipe 7. Scaffolding pipe pharmaceutical andship, building etc. |

| Advantages | Competitive price, High-quality products, 24-hour after-sales service |

| Port | Tianjin |

| Currency | USD, CNY, etc. |

| Payment | T/T, L/C, D/P, etc |

- Q: How do steel pipes handle extreme temperatures?

- Steel pipes can handle extreme temperatures due to their high strength and thermal stability. The properties of steel, such as its excellent heat resistance and low thermal expansion, allow it to withstand both high and low temperatures without significant deformation or structural damage. Additionally, the use of specialized coatings and insulation can further enhance the heat resistance of steel pipes, making them suitable for a wide range of applications in extreme temperature environments.

- Q: How are steel pipes protected against external impact or mechanical damage?

- Steel pipes are typically protected against external impact or mechanical damage through the use of various methods such as applying protective coatings, installing corrosion-resistant materials, using concrete encasement, or utilizing protective shields or guards.

- Q: Can steel pipes be used for steam applications?

- Yes, steel pipes can be used for steam applications. Steel pipes are known for their high strength and durability, making them suitable for carrying steam at high temperatures and pressures. They are resistant to corrosion and can withstand the harsh conditions of steam systems, making them a popular choice in various industries such as power generation, oil and gas, and chemical processing.

- Q: SC15 what does galvanized steel pipe look like?

- DN15 galvanized pipe, nominal diameter of 15mm

- Q: What are the different types of pipe connections used with steel pipes?

- Steel pipes are commonly connected using various types of pipe connections. The most frequently used connections are as follows: 1. Threaded connections: These connections involve screwing the ends of the pipe and using fittings with threads to connect them. They are typically used for smaller pipes and are easy to install and remove. 2. Welded connections: Welding is a popular method for joining steel pipes. This involves melting the metal and fusing the ends of the pipes together. Welded connections are strong and durable, making them suitable for high-pressure applications. 3. Flanged connections: Flanges are used to connect pipes by bolting them together. These connections are commonly used in industrial settings and are preferred for larger pipes or when easy disassembly is required for maintenance. 4. Grooved connections: Grooved fittings with internal grooves are used to connect pipes. These connections are commonly found in fire protection systems and are quick and straightforward to install. 5. Compression connections: Compression fittings are used to connect steel pipes by compressing a ferrule onto the pipe. This type of connection is frequently used in plumbing and provides a secure and tight seal. 6. Mechanical connections: Mechanical connections, such as couplings or clamps, allow for pipe connection without welding or threading. These connections are often used for temporary or emergency repairs. Each type of pipe connection has its own advantages and disadvantages. The choice of connection method depends on factors such as the application, pipe size, and installation requirements. It is crucial to carefully consider these factors to ensure a reliable and secure connection for steel pipes.

- Q: Can steel pipes be used for oil well casing?

- Yes, steel pipes can be used for oil well casing. Steel is a commonly used material for oil well casing due to its strength, durability, and resistance to corrosion.

- Q: How do steel pipes connect to other components?

- Steel pipes can be connected to other components using various methods, including welding, threading, flanges, and couplings. These connections ensure a secure and leak-proof joint between the steel pipe and other components, allowing for efficient fluid or gas transfer in various industries.

- Q: Can steel pipes be used for water supply lines?

- Indeed, water supply lines can utilize steel pipes. In the realm of industrial and commercial settings, steel pipes find frequent employment in the conveyance of water and other fluids. Their remarkable endurance and robustness render them highly suitable for systems operating under high pressure. Moreover, steel pipes exhibit exceptional resistance to corrosion, a crucial attribute for upholding water supply quality and safety. Nevertheless, it remains imperative to guarantee that steel pipes employed for water supply lines are adequately coated or lined to avert any potential water contamination.

- Q: What does "buried steel pipe" 6*2SC100 mean?

- This is the electrical drawings, such as water supply and drainage, HVAC is that DN, SC is the laying of electrical wiring, which is defined as threading pipe laying. 100 is the nominal diameter of the pipe, unit millimeters.

- Q: How are steel pipes transported from the manufacturing site to the construction site?

- Steel pipes are typically transported from the manufacturing site to the construction site using various methods, including trucks, trains, and ships. These transportation modes ensure efficient and cost-effective delivery, depending on the distance and infrastructure available.

Send your message to us

SHS RHS CHS square hollow section rectangular hollow section circular hollow section pipe & tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords