Aluminum Foil Facing Shield Cable Automotive Copper Shield Foil for Agricultural Equipment Electromotive Automobile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

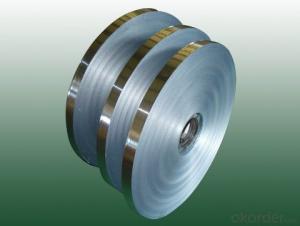

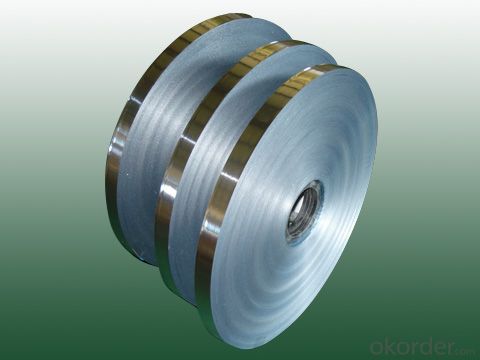

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

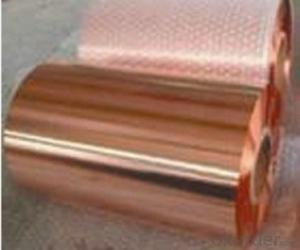

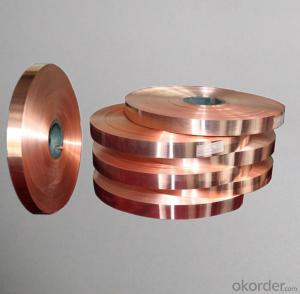

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the alternatives to using aluminum foil facing in various applications?

- <p>Yes, there are several substitutes for aluminum foil facing. These include: 1) Heavy-duty aluminum foil, which can be used for a more durable barrier. 2) Parchment paper, which is great for baking and resists tearing. 3) Silicone baking mats, reusable and non-stick. 4) Wax paper, useful for wrapping and storage but not for high heat. 5) Plastic wrap, suitable for food storage but not for cooking. 6) Tin foil, a cheaper alternative but less heat resistant. Always consider the specific needs of your application when choosing a substitute.</p>

- Q: This question asks for the proper method of using aluminum foil to wrap food, with emphasis on the correct side of the foil facing outward.

- <p>To wrap food correctly with aluminum foil, you should use the dull side of the foil facing outward, which is in contact with the food. The shiny side has a non-stick surface and is not recommended for direct food contact as it may contain substances that could potentially leach into the food when heated. Start by cutting a piece of foil large enough to fully cover the food. Place the food in the center, then fold the foil over, crimping the edges to seal tightly. This will help retain moisture and heat, and prevent any potential cross-contamination.</p>

- Q: Is it safe and practical to use aluminum foil facing as a substitute for a kitchen cutting board?

- <p>Using aluminum foil facing as a kitchen cutting board is not recommended. While it may seem like a convenient alternative, it can dull your knives quickly and may not be as sanitary as a proper cutting board. Aluminum foil is also not designed to withstand the pressure and friction of cutting, which could lead to tearing or puncturing the foil, potentially causing injury or contamination. It's best to use a cutting board made from materials like wood, plastic, or bamboo, which are specifically designed for food preparation and cutting.</p>

- Q: Is it possible to use aluminum foil facing more than once for various purposes?

- <p>Yes, aluminum foil facing can be reused for multiple purposes. It is commonly reused for cooking, baking, and food storage due to its heat resistance and reflective properties. For instance, you can use it to cover dishes in the oven, line baking sheets, or wrap food for storage. However, it's important to check for any tears or punctures after each use, as these can compromise its effectiveness and potentially lead to椋熷搧瀹夊叏 issues. Additionally, while it can be reused, it's not recommended to use it indefinitely as its performance may degrade over time.</p>

- Q: What are some lesser-known applications of aluminum foil in the kitchen?

- <p>Aluminum foil facing has several creative uses in the kitchen beyond just wrapping food. It can be used to cover baking dishes to prevent spills and messes in the oven, line baking sheets for easy cleanup, or create a makeshift roasting bag for cooking meats. It can also be used to sharpen knives by folding it into a book shape and running the blade through the sharp edges, or to create a non-stick surface for cooking by lining molds or baking pans. Additionally, it can be used to scrub pots and pans, removing stuck-on food, or to create a barrier between food and direct heat to prevent burning. These uses showcase the versatility of aluminum foil in the kitchen.</p>

- Q: What are the various levels or types of aluminum foil facing materials used in construction or insulation?

- <p>Aluminum foil facing is used in various applications such as insulation and construction. The different grades include: 1) Plain Aluminum Foil Facing, which is a basic type without any additional features. 2) Reinforced Aluminum Foil Facing, which is stronger and more durable, often used for heavy-duty applications. 3) Coated Aluminum Foil Facing, which has a protective coating for enhanced performance. 4) Laminated Aluminum Foil Facing, which combines aluminum with other materials for specific properties. Each grade offers unique benefits depending on the application's requirements.</p>

- Q: This question asks for the most effective method to smooth out wrinkles in aluminum foil facing material.

- <p>The best way to remove wrinkles from aluminum foil facing is to use a combination of heat and gentle stretching. First, preheat your iron on a low setting without steam. Place a thin cloth or parchment paper over the wrinkled aluminum foil facing to protect it from direct heat. Then, gently press the iron over the cloth, moving in a smooth, continuous motion. As the foil warms, it will become more pliable, allowing you to gently stretch and smooth out the wrinkles. Be cautious not to apply too much pressure or heat, as this can damage the foil.</p>

- Q: This question asks for the method of wrapping food using aluminum foil.

- <p>To wrap food with aluminum foil, first clean your hands and ensure the foil is shiny side out. Cut a piece of foil large enough to cover the food completely. Place the food in the center of the foil. Bring the edges of the foil together over the food, then fold and crimp the edges to seal tightly. Ensure there are no gaps to prevent the food from drying out or the foil from tearing. For more complex shapes, you can double the foil and create a pouch or tent, folding the edges to secure the shape. Always handle food with clean hands to maintain hygiene.</p>

- Q: The user wants to know if they can reuse their old aluminum foil facing to create a new one if it gets damaged.

- <p>Yes, you can use your old aluminum foil facing to make a new one if it gets damaged. Simply clean the old foil facing thoroughly, ensuring all adhesive residue is removed. Then, cut a new piece of aluminum foil to the appropriate size and shape. Apply a thin layer of adhesive, such as construction adhesive or double-sided tape, to the back of the new foil. Press it firmly onto the old facing, ensuring a smooth and secure bond. Allow it to dry according to the adhesive's instructions before using. This can be a cost-effective way to extend the life of your foil facing.</p>

- Q: Does using aluminum foil facing have any positive effects on health when baking bread?

- <p>Using aluminum foil facing when baking bread does not directly provide health benefits. However, it can help in achieving a more even bake and a better crust, which may enhance the overall quality of the bread. Aluminum foil facing can also prevent bread from burning by reflecting heat away from the bread's surface. While this doesn't impact health, it can improve the bread's taste and texture, which might indirectly contribute to a more enjoyable eating experience and potentially encourage healthier food choices.</p>

Send your message to us

Aluminum Foil Facing Shield Cable Automotive Copper Shield Foil for Agricultural Equipment Electromotive Automobile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords