SG series Dry Granulating machine - granulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

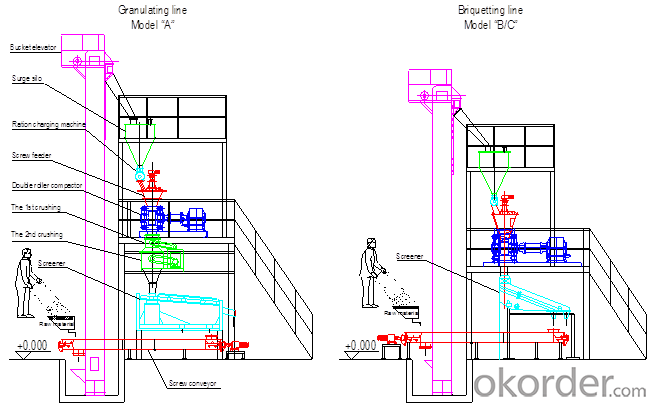

1、Structure of SG series Dry Granulating machine

SG series Dry Granulating machine consist of various types of granulation equipments based on the dry method while the basic principle is the same. The dry powder material from the top to join, by deaeration, spiral preload to enter the gap between the rollers, the rollers of great pressure cause the material plastic deformation is compacted into a sheet. The sheet material is then crushed and screened to get the final granular products. The compacting pressure can be adjusted by the hydraulic cylinders according to the requirements of the granulation operation. Different pressure settings can get granular products of different strength.

2Main Features of the SG series Dry Granulating machine

•The material is compacted into granules/briquettes through mechanical pressure, without adding any wet agent. The product purity is guaranteed.

•The process flow has shorter and lower in power consumption as well as less accessory equipment and worker.

•The dry powder can be granulated directly. No need of further drying.

•Higher granule strength. Bulk specific gravity improvement is more obvious than other granulation methods.

•More flexibility in operation. Wide application. The size of granule/briquettes strength can be adjusted through hydraulic pressure.

•The system is closed loop operation realizing the continuous production

3 The SG series Dry Granulating machine Finished products imagine

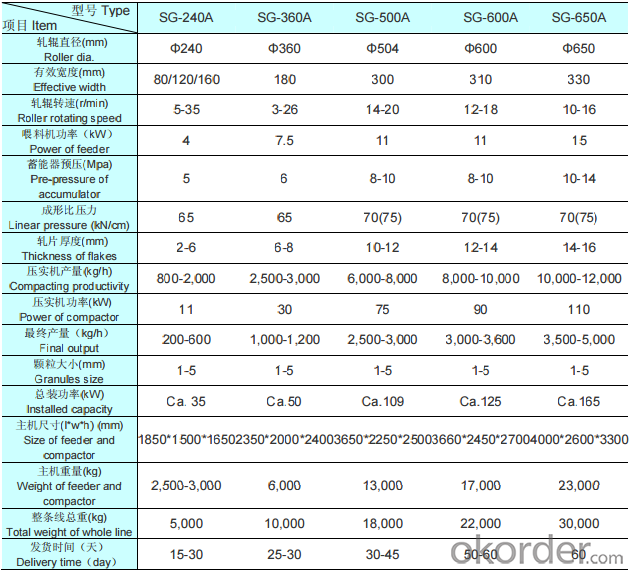

4 The SG series Dry Granulating machine Specification

5.FAQ

①How to guarantee the quality of the products?

Any product delivered by our company, we will designate the technical to install and adjust, provide the best service for the customers. We will also provide necessary follow-up service assurance. Since the customer checks and accepts the equipment, the equipment is guaranteed for one year and maintained for the whole life.

- Q: What are the mechanical devices?

- Packing equipment: link equipment, packaging, testing equipment, packaging containers manufacturing equipment, packaging equipment, filling machinery barcode equipment, labeling machine, multi-function packaging machine, wrapping package machine, sealing machine, filling machine, strapping machine, drying machine

- Q: Why is the volume of the chemical plant bulky

- One, large capacity has capacity; The necessary conditions for the chemical reaction. A chemical plant, as the name suggests, is a factory that reacts chemically to produce goods. Chemical reactions, you know, chemical reactions, if you don't have to heat it up, you're going to get a lot of heat out of it. Produce high temperature and high pressure gas or product. To get qualified in the case of a controlled product, chemical reactions must be provided the required conditions, the reaction kettle is enough big, can provide enough quantity, and fully contact materials. At the same time, there is also a circulating water device to cool down or heat the steam. In addition, the output of the chemical reaction (often multiple, the main produce and the secondary output), also has to be large enough to be dressed up. So, smaller chemical plants, and there are a few essential devices, and they're going to be very large.

- Q: What kind of production equipment do petrochemical industry use,

- Mixer, compressor, pipe, heat exchanger, air cooling, towerReaction kettle, rectification tower, heat exchanger...

- Q: What is the electrical equipment of the chemical plant? How do you solve the lubrication problem

- China equipment management network Content involves: industry information, equipment management, equipment maintenance, monitoring and diagnosis, lubrication sealing, energy conservation, environmental protection and management of heaven and earth, theory method, terms, equipment procurement, communication BBS, etc. Covers all aspects of equipment management and maintenance. It is an ideal place for workers to learn and communicate. It is an ideal platform for the enterprise to release information about the supply and demand of products. Chinese equipment...

- Q: What are the characteristics of chemical equipment

- Required chemical equipment to normal temperature, pressure, flow rate, material corrosion, such as operating conditions, the structure strength of materials and have enough sealing property and mechanical strength. To have sufficient experience and preparedness, contingency and disposition of the extreme conditions that may arise, and may even arise. (4) both continuous and intermittent chemical production devices require long-term operation. Therefore, it is necessary to consider the wear and corrosion of chemical equipment, and ensure that there is sufficient life span.

- Q: How to enter oneself for an examination?

- Qualification examination requirement of registered chemical engineer The basic examination of registered chemical engineers shall meet one of the following conditions: An undergraduate or above degree in this major or similar professional university. The article is a professional or similar specialized college degree, and has been engaged in chemical engineering design for one year. Bachelor degree or above, bachelor degree or above in other engineering major, I have been engaged in chemical engineering design for one year.

- Q: There are chemical products for machining

- Mechanical processing is a process of changing the shape or performance of the workpiece by machining machine. The temperature state of the workpiece is divided into cold processing and hot processing. It is usually processed at room temperature and does not cause chemical or material change in the workpiece, which is called cold machining. In the case of a process that is above or below normal temperature, the chemical or object of the workpiece is changed, which is called hot machining. The difference in processing mode can be divided into machining and pressure processing. Hot processing is common in heat treatment, calcining, casting and welding. Various kinds of equipment, general term: heat treatment equipment, forging equipment, casting equipment, welding equipment, metal cutting machine, press, etc. The big categories of metal cutting machine tools are: car, drill, boring, grinding, gear processing, milling, plane, pull, special machine tool, etc.

- Q: The overall requirements of the products for the fans are higher

- Gas recovery unit, dust removal device, exhaust device, etc.

- Q: What can be used for titanium or titanium alloy materials in the chemical industry?

- After years of promotion, titanium and its alloys have been as a kind of excellent corrosion resistant structure materials has been widely used in chemical production. At present, the application of titanium equipment has from the initial "soda ash and caustic soda industry" extended to chlorate, ammonium chloride, urea, organic synthesis, dyes, inorganic salt, pesticide, synthetic fiber, fertilizer, and fine chemical industries, types of equipment has expanded from small, simplification to large and diverse. Chemical sector is expected, the chemical industry with titanium content of more than 1500 tons. At present, the domestic chemical titanium equipment, is the largest number of heat exchanger, followed by titanium anode and container. The results of the survey showed that 56.66% titanium heat exchanger, titanium anode (20.41%), titanium vessel accounted for 16.28%, other 6.65%. Titanium in the dosage of chemicals used in the earliest, the largest is the chlor-alkali industry, at present the national medium chloralkali plant nearly 200, most of them adopt titanium anode tank and ionic membrane electrolyzer caustic soda production, so the titanium equipment with bigger quantity.

- Q: What is the production and attention of water treatment in chemical industry?

- Do you have the equipment to make ultra-pure water? Is there any equipment

Send your message to us

SG series Dry Granulating machine - granulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords