Sen Monolithic Refractories for Iron and Steel Industry Melting Furnace Refractory Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

sen

Long life

Reliable

ISO9001

High thermal shock resistance.

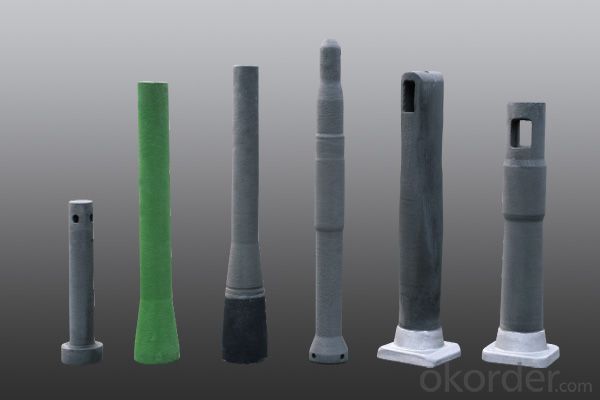

1.New type Composite subemeged nozzle

Advantage

long life,10hours

high thermal shock resistance

and reliable flow control.

Applicable to the C.C. of the billet, slab, round and bloom for the converter, and EAF,

pouring for more than 400 min .

Application

Applicable to the C.C. of the billet, slab, round and bloom for the converter, and EAF, pouring for more than 400 min,and compositions and specifications can be adjusted according to the specific requirement of the customer.

Specifications

No. | SK6-7 | SK6-8 | SK6-9 | SK6-10 | SK6-11 | SK6-12 |

Name | Submerge entry nozzle(SEN) | |||||

Body | Slag-band | Body | Slag-band | Body | Slag-band | |

Al2O3 % | ≥45 | ≥45 | ≥50 | |||

C+SiC % | ≥30 | ≥13 | ≥30 | ≥13 | C≥26 | ≥13 |

ZrO2 % | ≥4 | ≥75 | ≥4 | ≥75 | ≥3 | ≥75 |

B.D.g/cm3 | ≥2.3 | ≥3.5 | ≥2.3 | ≥3.5 | ≥2.25 | ≥3.5 |

A.P. % | ≤19 | ≤19 | ≤19 | ≤19 | ≤18 | ≤19 |

CCS MPa | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 |

H.M.O.R MPa |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

Thermal shock resistance times |

≥5 |

≥5 |

≥5 |

≥5 |

≥5 |

≥5 |

Details of Al2O3-ZrO2-C Al2O3 anti-clogging SEN |

Series of Al2O3-ZrO2-C material in the body can be applied to different steel grades. The latest new type of low silica material has more higher thermal stability, erosion resistance compared with traditional materials.

Series of compound materials for slag line. |

- Q: How do monolithic refractories improve the efficiency of reheating furnaces in steel plants?

- The efficiency of reheating furnaces in steel plants is greatly improved by the use of monolithic refractories. Specifically designed to withstand high temperatures and harsh conditions, these refractories are an ideal choice for steel plants. One important way in which monolithic refractories enhance furnace efficiency is by decreasing heat loss. With their excellent insulation properties, these refractories minimize the transfer of heat from the furnace to its surroundings. As a result, less energy is wasted and the furnace can maintain its desired temperature more effectively. Furthermore, monolithic refractories contribute to a more uniform and controlled distribution of heat within the furnace. They can be easily shaped and installed to create a seamless lining, ensuring that heat is evenly spread throughout the furnace chamber. This even distribution of heat eliminates any hotspots or cold spots, resulting in a more efficient heating process. Another crucial role of monolithic refractories is reducing downtime and maintenance requirements. Unlike traditional brick linings, which are prone to cracking and erosion, monolithic refractories offer superior resistance to wear and tear. This increased durability reduces the need for frequent repairs and replacements, allowing for uninterrupted furnace operation and increased overall efficiency. Moreover, monolithic refractories help improve energy efficiency by decreasing fuel consumption. The superior insulation properties of these refractories help retain heat within the furnace, reducing the amount of energy needed to maintain the desired temperature. This leads to significant energy savings for steel plants, as less fuel is required to achieve the same heating results. In conclusion, the efficiency of reheating furnaces in steel plants is significantly enhanced by the use of monolithic refractories. These refractories reduce heat loss, ensure uniform heat distribution, minimize downtime and maintenance, and decrease fuel consumption. By incorporating these refractories into their furnace linings, steel plants can increase productivity, reduce energy costs, and improve overall operational efficiency.

- Q: Can monolithic refractories be used in electric arc furnaces and induction furnaces?

- Yes, monolithic refractories can be used in both electric arc furnaces and induction furnaces. Monolithic refractories are versatile and can withstand the high temperatures and thermal shocks generated in these types of furnaces. They are often preferred due to their ease of installation, improved energy efficiency, and suitability for various furnace lining applications.

- Q: What are the key properties of ramming mixes used for monolithic refractory installations?

- The key properties of ramming mixes used for monolithic refractory installations are: 1. High thermal stability: Ramming mixes should possess high thermal stability to withstand the extreme temperatures and thermal cycling in refractory applications. This property ensures that the ramming mix remains intact and does not undergo significant structural changes under varying thermal conditions. 2. High density: Ramming mixes need to have a high density to provide good resistance against thermal conductivity. This property helps in minimizing heat loss and maintaining the desired temperature in the refractory lining. 3. Low porosity: Low porosity is essential for ramming mixes as it helps in reducing the penetration of molten metals or slag into the refractory lining. This property enhances the overall durability and longevity of the refractory installation. 4. Good mechanical strength: Ramming mixes should possess good mechanical strength to withstand the stresses and loads encountered during installation, as well as during the operation of the refractory lining. This property ensures that the ramming mix can resist any physical or mechanical damage, such as cracking or spalling. 5. Chemical resistance: Ramming mixes should exhibit excellent resistance to chemical attack from molten metals, slag, or corrosive gases. This property is crucial for protecting the refractory lining from chemical reactions and degradation, which can compromise its performance and lifespan. 6. Easy installation and workability: Ramming mixes should have good workability, allowing for easy installation and compaction. This property ensures that the mix can be easily shaped and rammed into place without excessive effort or time, facilitating efficient and effective refractory installations. 7. Controlled setting time: Ramming mixes should have a controlled setting time to allow sufficient time for proper placement and consolidation. This property ensures that the mix remains workable during installation but sets and hardens within a reasonable time frame, allowing for timely completion of the refractory lining. In summary, the key properties of ramming mixes used for monolithic refractory installations include high thermal stability, high density, low porosity, good mechanical strength, chemical resistance, easy installation and workability, and controlled setting time. These properties collectively contribute to the overall performance, durability, and longevity of the refractory lining in various high-temperature applications.

- Q: What are the main factors affecting the corrosion resistance of monolithic refractories?

- The main factors affecting the corrosion resistance of monolithic refractories include the chemical composition of the refractory material, the temperature and atmosphere in which it operates, the physical properties of the refractory such as porosity and permeability, and the presence of impurities or aggressive agents. Additionally, the design and installation of the refractory lining, as well as the operational practices and maintenance of the system, can also impact its corrosion resistance.

- Q: How do monolithic refractories contribute to the quality of iron and steel products?

- Enhancing the quality of iron and steel products is a crucial role played by monolithic refractories. These refractories consist of a single, solid structure that grants them high resistance against thermal and mechanical stresses. Their unique properties make them suitable for a range of high-temperature applications in the iron and steel industry. To start with, monolithic refractories excel in thermal insulation, maintaining a consistent temperature within furnaces and kilns. This temperature stability is vital for the proper heat treatment of iron and steel, ensuring ideal metallurgical properties and reducing the risk of defects. By preventing heat loss, monolithic refractories promote efficient energy utilization, resulting in cost savings and environmental benefits. In addition, monolithic refractories demonstrate remarkable endurance in the face of harsh operating conditions. The iron and steel manufacturing process involves extreme temperatures, aggressive chemical environments, and mechanical stresses. Monolithic refractories exhibit exceptional resistance to these conditions, ensuring durability and longevity. Their ability to resist thermal shock prevents cracking or spalling, which can lead to contamination and compromised product quality. Furthermore, monolithic refractories provide excellent corrosion resistance, shielding iron and steel products from chemical reactions with molten metal, slag, and other aggressive substances. This resistance not only preserves the integrity of the refractory lining but also prevents contamination of the metal, resulting in improved product quality. Monolithic refractories also offer flexibility in design and installation. They can be shaped, cast, or gunned into various complex geometries, allowing for customization based on the specific requirements of the iron and steel production process. This versatility ensures optimal lining performance, maximizing efficiency and product quality. In conclusion, monolithic refractories significantly contribute to the quality of iron and steel products. Their thermal insulation properties, resistance to harsh operating conditions, corrosion resistance, and design flexibility all play a vital role. By providing a reliable and durable lining in high-temperature applications, monolithic refractories help guarantee consistent and high-quality output in the iron and steel industry.

- Q: How do monolithic refractories perform in electric arc furnace roof applications?

- Due to their unique properties and characteristics, monolithic refractories are extremely effective when used in electric arc furnace (EAF) roof applications. Comprised of a single, solid material, these refractories offer several advantages specific to this application. To begin with, monolithic refractories provide exceptional thermal insulation, a critical factor in EAF roof applications. Traditional brick refractories can suffer structural damage from the intense heat generated in the furnace. However, monolithic refractories possess a higher resistance to thermal shock, reducing the risk of cracking and spalling. This ensures that they maintain their integrity and insulation properties even under extreme temperature conditions. Furthermore, monolithic refractories exhibit high strength and abrasion resistance, guaranteeing their durability and longevity in EAF roof applications. The roof of an electric arc furnace is subjected to harsh conditions, including the impact of scrap materials and the erosive effects of molten metal and slag. Monolithic refractories are specifically designed to withstand these challenges, offering superior resistance to mechanical wear and erosion. Another advantage of monolithic refractories lies in their ease of installation. Unlike traditional brick refractories, which necessitate time-consuming and complex installation processes, monolithic refractories can be applied rapidly and efficiently. They can be cast, gunned, or sprayed onto the roof surface, adapting to any shape or contour. Consequently, installation or repair downtime is reduced significantly. Moreover, monolithic refractories contribute to increased energy efficiency in EAF roof applications. Their superior insulation properties minimize heat loss, resulting in reduced energy consumption and cost savings. This is particularly crucial for electric arc furnaces, as their efficiency and productivity heavily rely on maintaining high temperatures for metal melting and processing. Any heat loss can have a significant impact on these factors. In conclusion, monolithic refractories are highly suitable for electric arc furnace roof applications due to their exceptional thermal insulation, strength, abrasion resistance, ease of installation, and energy efficiency. These refractories offer significant advantages over traditional brick refractories, ensuring optimal performance and extended service life in the demanding environment of an electric arc furnace.

- Q: How do monolithic refractories withstand thermal shock?

- Monolithic refractories withstand thermal shock due to their unique composition and structure. They are made from a single, continuous material with no joints or seams, which allows them to expand and contract uniformly under extreme temperature changes. Additionally, monolithic refractories possess excellent thermal conductivity, which enables them to quickly dissipate heat and minimize stress build-up. These properties make them highly resistant to thermal shock and capable of withstanding rapid temperature fluctuations without cracking or breaking.

- Q: How do monolithic refractories contribute to the safety of iron and steel plants?

- Monolithic refractories play a crucial role in ensuring the safety of iron and steel plants. These refractories are specially designed to withstand high temperatures, chemical attacks, and mechanical stresses commonly encountered in these industrial settings. By utilizing monolithic refractories, iron and steel plants can benefit in the following ways: 1. Thermal resistance: Monolithic refractories have excellent resistance to extreme temperatures, preventing heat loss and ensuring the efficient operation of various equipment and systems. This thermal insulation contributes to the safety of the plant by reducing the risk of overheating, which could lead to equipment failure or even catastrophic accidents. 2. Chemical resistance: Iron and steel plants involve the use of various chemicals, including molten metal, slag, and corrosive gases. Monolithic refractories exhibit high resistance to these aggressive chemical environments, preventing corrosion, erosion, and material degradation. This resistance ensures the integrity of refractory linings, reducing the risk of leaks, spills, and contamination that could jeopardize the safety of workers and the environment. 3. Structural stability: Monolithic refractories provide excellent mechanical strength, offering structural stability to the linings of furnaces, ladles, and other equipment. This stability is crucial for the safe operation of iron and steel plants, as it minimizes the risk of structural failure, collapse, or damage caused by mechanical stresses or heavy loads. 4. Rapid repair and maintenance: Monolithic refractories offer the advantage of easy installation and repair compared to traditional brick refractories. Their application involves pouring, gunning, or ramming the refractory material in place, which allows for quick repairs and maintenance. This rapid response to refractory failures or damages contributes to the plant's safety by minimizing downtime and preventing potential hazards associated with equipment malfunction. 5. Flexibility and adaptability: Monolithic refractories can be tailored to meet the specific needs and requirements of iron and steel plants. They can be customized in terms of composition, density, thermal conductivity, and other properties, allowing for optimal performance under varying operating conditions. This adaptability ensures that refractory linings are well-suited for the plant's processes, reducing the likelihood of accidents or incidents caused by inadequate refractory materials. In summary, monolithic refractories enhance the safety of iron and steel plants by providing thermal resistance, chemical resistance, structural stability, rapid repair capabilities, and flexibility. By utilizing these refractories, iron and steel plants can maintain a safe working environment, minimize the risk of accidents, and ensure the reliable operation of their equipment and systems.

- Q: How do monolithic refractories improve the durability of furnace linings?

- Monolithic refractories improve the durability of furnace linings by providing a seamless and continuous structure that eliminates joints and weak points. This eliminates the risk of thermal shock and cracking, resulting in a longer lifespan for the furnace lining. Additionally, monolithic refractories offer better resistance to chemical attack, abrasion, and thermal stress, further enhancing the durability of the furnace lining.

- Q: What are the benefits of using monolithic refractories in the iron and steel industry?

- Using monolithic refractories in the iron and steel industry has several advantages. Firstly, they have excellent thermal shock resistance, meaning they can withstand extreme temperature changes without cracking or spalling. This is crucial in an industry where materials are exposed to high temperatures during processes such as melting, casting, and heat treatment. Secondly, monolithic refractories have superior corrosion resistance, making them highly durable against the corrosive effects of molten metals and slag. This is particularly important in the iron and steel industry, where materials come into contact with aggressive molten iron, steel, and various chemical compounds. Furthermore, monolithic refractories provide excellent mechanical strength and abrasion resistance. They can withstand mechanical stress, vibrations, and impacts commonly encountered in the iron and steel industry. This ensures a longer lifespan for the refractories, reduces downtime for repairs or replacements, and improves overall operational efficiency. Additionally, monolithic refractories offer ease of installation and repair. Unlike traditional refractory bricks that require complex and time-consuming masonry work, monolithic refractories can be quickly and easily installed using simple methods such as casting, gunning, or spraying. This saves time and labor costs during initial installation and subsequent maintenance or repairs. Moreover, monolithic refractories provide flexibility in design and application. They can be customized to specific shapes and sizes, allowing for tailored linings in different parts of the iron and steel manufacturing process. This versatility enhances the overall efficiency and effectiveness of refractory linings, optimizing production output and ensuring consistent quality of the finished iron and steel products. In conclusion, there are numerous benefits to using monolithic refractories in the iron and steel industry. They offer exceptional thermal shock resistance, corrosion resistance, mechanical strength, and abrasion resistance. They are also easy to install and repair, and their flexibility allows for customized designs. Overall, monolithic refractories contribute to improved productivity, reduced downtime, and enhanced product quality in the iron and steel industry.

Send your message to us

Sen Monolithic Refractories for Iron and Steel Industry Melting Furnace Refractory Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords