Round Ductile/ Cast Iron D400 Manhole Cover with Frame (DN600)

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects.

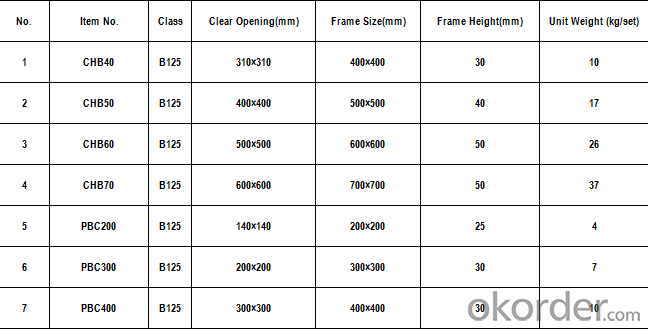

Specifications:

About Our Company:

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

Feature:

1)Product information

Surface is smooth , free from sand holes, blow holes, distortion or any other defects.

2)Material Ductile Iron GGG500 / Grey Iron GG20.

3) Designs As per customers' drawings or samples.

4)Process Green sand with hand molding.

5) Coating Black Bitumen Coated, Without coating or Coating as per customers' requirement.

6)Packing wooden pallet with plastic layer or according to customers' request

We are an ISO9001:2000 certified enterprise in China, specializing in manufacturing various kinds of of ductile iron grating manhole covers .

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

Pictures:

Packaging & Shipping:

1.Packaging: Details Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 30-45 days.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The first to ask, such as casting end cover, bed and other products, is to put the iron melting and casting againThe two question, their casting castings manufacturers than to buy professional casting factory production, production quality more security professional.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Problem one,1, according to drawings, castings, material requirements and machine power, choose the right diameter of roughing tools, and can process this material blade type.2, according to the actual size of the casting blank, calculate the number and path of the knife, pay attention to small cutting depth, large feed, cutting width, to ensure that the tool diameter 80 - 90%, the amount of not full knife cutting, this tool and machine tool damage.Question two,If they can not change the casting blank allowance under the condition that the quantity large diameter cutter, such as milling cutter main angle 7560 degrees can give reasonable processing parameters, the same cutting depth should not be too large, because in the same machine power, tool diameter increases, cutting depth will need smaller.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

Send your message to us

Round Ductile/ Cast Iron D400 Manhole Cover with Frame (DN600)

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords