Round and Square Ductile Iron Manhole Cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

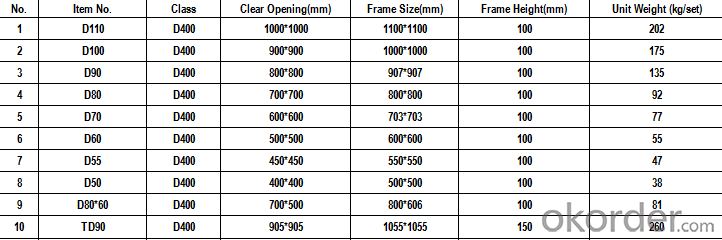

Specification

Quick Details

· Brand Name: CMAX

· Model Number: EN124 Standard

· Application: Construction

· Material: Iron

· Dimensions: OEM

· Surface treatment: Painting

· Process: Casting. Deburring .Drilling .threading

· Certification: ISO9001:2008

· Standard: EN124 Standard

· Name: Iron Casting Parts

· Color: Grey

· Type: Moulding Press

· Service: OEM Service

· Size: Customer's Request

Packaging & Shipping

· Packaging: Details Pallet with bubble film, Carton or with pallet,

· Delivery Detail: 30-45 days

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

Our Services

· 1. Sample is available for free.

· 2. OEM and ODM are welcome.

· 3. Free charge of design labels and cartons.

· 4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

· 5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

· 7. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1.Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.How long can you make your quotation:

Within 3 workdays after received your detailed product information

3. Do you provide OEM Service?

Yes, we provide OEM Service.

4. What 's your quotation element?

Drawing, material, weight and quantity.

- Q: How to improve the surface roughness of casting parts?

- First, the accuracy of the model should be improved; two is to change the molding technique; the three is the coating; and the worker's technical level.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- You oily sludge!Is not the general market on the soil?If it isPlease use two groups of chemicals to reinforce the soilOr suggest your company?Do the putty or paint film after doingThat's better

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The first to ask, such as casting end cover, bed and other products, is to put the iron melting and casting againThe two question, their casting castings manufacturers than to buy professional casting factory production, production quality more security professional.

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Valve sand core mold drying is not in place, excessive water content

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- There is YW1 best, if not using YG6X, YG8 is ok!The speed should not be high, the greater the diameter, the lower the speed! For example, a diameter of 100 mm, speed is not greater than 80 rpm, each point is good!The main tool is the front angle to be larger, more than 6 degrees, and the groove should be wider and larger to reduce the cutting resistance! When the rear angle is properly reduced and the strength is increased, it is recommended to take 3 degrees.The main components are: spindle box, exchange gear box, feed box, slide box, tool post, tail frame, light bar, lead screw, bed, foot and cooling device.Spindle box: also known as the headstock, it is the main task of the rotary motion of the main motor came through the transmission mechanism of a series of positive and negative spindle to be required two different steering speed, the spindle box gives impetus to the movement of the box. Medium spindle is the key part of lathe. The stability of the spindle on the bearing directly affects the quality of the workpiece. Once the rotation accuracy of the main shaft is reduced, the value of the machine tool will be lowered.

Send your message to us

Round and Square Ductile Iron Manhole Cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches