Plastic Sheets - Rigid PVC Foam Board 3D for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

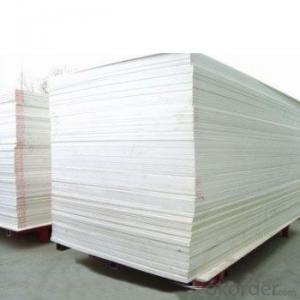

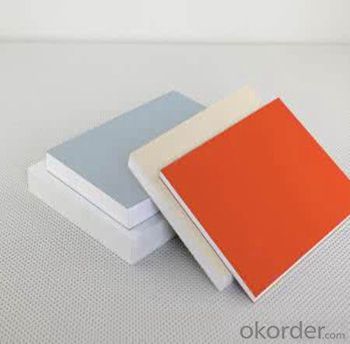

PVC Foam Board 3D for construction

1.Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anti-corrosive ametabolic and recyclable,moisture resistant,lightweight.

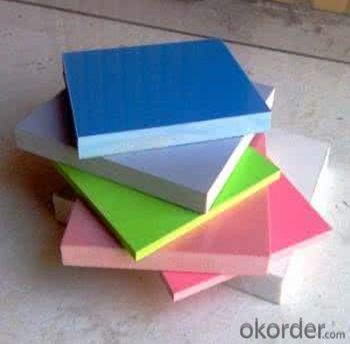

2.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

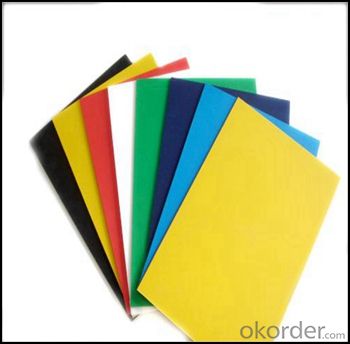

Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

Executive standard | QB/T 2463.1-1999 |

Certificate | SGS |

Weldable | Yes |

Foam Process | Celuka |

Packing | Carton box or wooden pallet packing |

production capability | 10000 pcs per month |

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

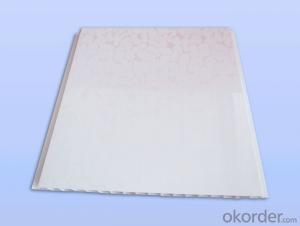

Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

5. Characteristics:

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding printability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

6.FAQ:

1. Q; Advantages of your products?

A:Company products, good quality, high reputation guarantee.

2. Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

3. Which Payment Terms?

ALi Trade Assurace, T/T(Telegraphic Transfer), West Union, L/C etc.

4. Lead Time: How soon we can get the shipment?

Usually, it's within 7-15 working days after receiving payment.

7. Pictures:

- Q: Can plastic sheets be molded into different shapes?

- Yes, plastic sheets can be molded into different shapes using various techniques such as thermoforming or injection molding.

- Q: Are plastic sheets suitable for outdoor furniture?

- Plastic sheets can be suitable for outdoor furniture, depending on the specific type of plastic used. Some plastics, such as high-density polyethylene (HDPE), are specifically designed to withstand outdoor conditions and resist fading, cracking, or warping due to sunlight, moisture, and temperature changes. It is essential to choose plastic sheets that are UV-stabilized and weather-resistant to ensure their durability and longevity when exposed to the elements.

- Q: Are plastic sheets resistant to bending under heavy loads?

- Yes, plastic sheets are generally resistant to bending under heavy loads, especially those made from high-density polyethylene or polycarbonate. These materials have excellent strength and flexibility, allowing them to withstand considerable pressure without bending or breaking.

- Q: How do plastic sheets handle static electricity?

- Plastic sheets, being insulators, tend to accumulate static electricity rather than conducting it. This means that they can build up a charge when in contact with other materials or through friction. However, their ability to dissipate or discharge this static charge is generally low.

- Q: Are plastic sheets resistant to warping or expanding with temperature changes?

- Yes, plastic sheets are generally resistant to warping or expanding with temperature changes.

- Q: Conservatives, are you not embarrased that you are so easily fooled?

- weeds don't grow in my flower bed. i delayed for two years upgrading to copper pipes cuz the duct tape stopped my leaks. bought some Exxon stock in the meantime. all this while those idiot conservatives in charge lowered the capital gains tax. yes, i am indeed embarrassed that NOT

- Q: I am trying to fugure out how to create a flexable seem out of a sheet of plastic. For example if you had a 12x12 sheet of plastic 1/16 thick and you wanted to fold it in half to create two 6x12 flaps. How would you create a seem at the fold that could be easly folded and unfolded repeatedly for a long duration?

- You could do this with a living hinge. Co-extrude the plastic profile with rigid plastic connected with the flexible plastic living hinge. Long duration needs to defined.

- Q: How can I remove the glass glue on the aluminum plate?

- Its specific steps:1, the first place with more plastic scraping scraping;2, the surface of residual, and then xylene, acetone, banana water or gasoline scrub can.

- Q: Are plastic sheets resistant to cracking in cold temperatures?

- Yes, plastic sheets are generally resistant to cracking in cold temperatures due to their low temperature brittleness.

- Q: What are the disadvantages of using plastic sheets?

- One major disadvantage of using plastic sheets is their negative impact on the environment. Plastic is non-biodegradable and takes hundreds of years to decompose, contributing to pollution and litter. Additionally, the production of plastic sheets involves the extraction and processing of fossil fuels, contributing to climate change and depletion of natural resources. Plastic sheets are also prone to tearing and damage, making them less durable compared to other materials.

Send your message to us

Plastic Sheets - Rigid PVC Foam Board 3D for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords