Strataweb Geocells Reinforcement Uniaxial PP Geogrid

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

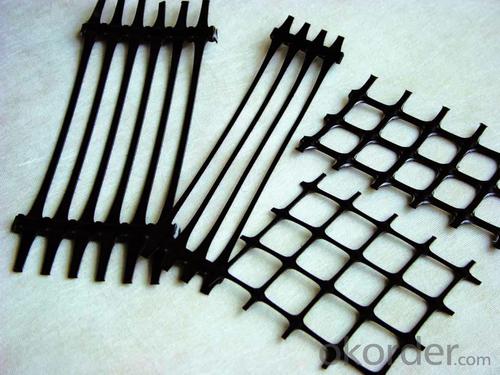

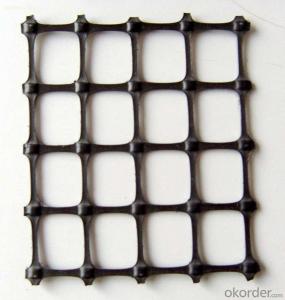

Double-direction geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

2. Product Characteristic:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Enhance earth slope and prevent water loss and soil erosion.

5. Decrease underlayer thickness and save manufacturing cost.

3.Specification :

Item | TGSG15-15 | TGSG20-20 | TGSG25-25 | TGSG30-30 | TGSG40-40 |

Longitudinal Tensile Strength,kN/m | 15 | 20 | 25 | 30 | 40 |

Transverse Tensile Strength,kN/m | 15 | 20 | 25 | 30 | 40 |

Longitudinal Yield Elongation,% | 15 | ||||

TransverseYield Elongation,% | 13 | ||||

Longitudinal Yield Strength at 2% Elongation,kN/m | 5 | 7 | 9 | 11 | 14 |

Transverse Yield Strength at 2% Elongation,kN/m | 5 | 7 | 9 | 11 | 14 |

Longitudinal Yield Strength at 5% Elongation,kN/m | 7 | 14 | 17 | 21 | 30 |

Transverse Yield Strength at 5% Elongation,kN/m | 7 | 14 | 17 | 21 | 30 |

Product Length/roll,m | 50 | 40 | |||

Product width ,m | 3.9/3.95/4 | ||||

4. Reference Picture:

- Q: Can geogrids be used in reinforcement of bridge abutments on expansive soils?

- Yes, geogrids can be used in reinforcement of bridge abutments on expansive soils. Geogrids are effective in providing soil stabilization and preventing soil movement, which is particularly important in areas with expansive soils that tend to expand and contract with moisture content changes. By using geogrid reinforcement, the bridge abutments can be better protected against potential soil movement, reducing the risk of structural damage.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids are extensively used in civil engineering for various applications such as soil stabilization, slope reinforcement, retaining wall construction, and pavement reinforcement. They provide strength and stability to soil structures, prevent erosion, increase load-bearing capacity, and enhance overall structural integrity. Geogrids are also employed in infrastructure projects like road construction, railway tracks, landfill sites, and coastal protection, contributing to the longevity and durability of these civil engineering projects.

- Q: What are the design guidelines for geogrid-reinforced structures?

- The design guidelines for geogrid-reinforced structures typically include factors such as selecting the appropriate geogrid material and type, determining the required strength and stiffness of the geogrid, considering the soil properties and conditions, and ensuring proper installation and connection of the geogrid to the surrounding structure. It also involves evaluating factors such as load distribution, settlement, and durability to ensure the stability and long-term performance of the reinforced structure.

- Q: What is the elongation of fiberglass geogrid?

- Hope to help you

- Q: Glass fiber grating with large pulling force for Expressway

- To improve the overall use of polyester geogrid using high strength nylon fiber filament, warp knitting mesh fabric.

- Q: What are the specifications and models of Geotextiles and geogrids on the highway

- One way plastic geogrid TGDG25 TGDG50 TGDG110 TGDG120 TGDG180 width of 1 m -3 m TGDG150 (TGDG35) TGDG80Bidirectional geogrid TGSG15-15 TGSG25-25 TGSG30-30 TGSG40-40 width 2-5M meters (TGSG20-20)

- Q: Geogrid GSZ 100 50/PP what does it mean

- The rear PP should be the PP solder grid.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: Fiberglass grille and geogrid which use more

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. The glass fiber geogrid belongs to the geogrid, which is more natural than the glass fiber geogrid.

- Q: Can geogrids be used in reinforcement of gabion walls?

- Yes, geogrids can be used in the reinforcement of gabion walls. Geogrids are commonly used to enhance the stability and strength of gabion structures by providing additional tensile strength and preventing soil erosion. This reinforcement technique helps to increase the overall structural integrity and durability of gabion walls.

Send your message to us

Strataweb Geocells Reinforcement Uniaxial PP Geogrid

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords