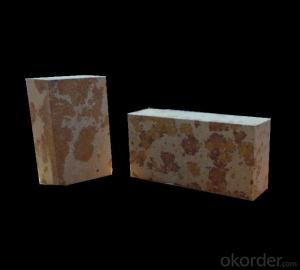

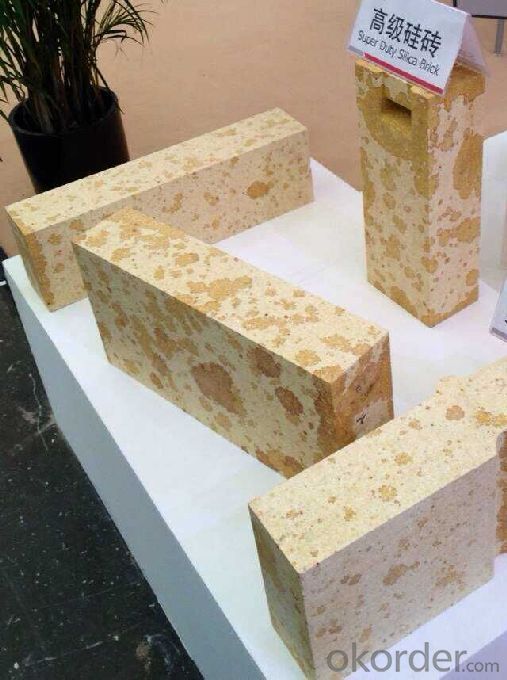

Raw Materials for Refractory:High Density Silica Brick 95B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: What kind of material is good for cabinet fireproof board

- What kind of material is good for cabinet fireproof board What are the advantages and disadvantages of using it? How much is the price? A about how much does one piece cost?

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level 2, the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is less than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd.

- Q: What is the classification standard of fireproofing material levels?

- Standard: Class A: Incombustible building material, almost without burning. class A1: Non-combustible, no open flame,class A2: Non-combustible,it needs to measure smoke and be qualified. Class B1: Nonflammable building material: Nonflammable materials have good flame resistance function. when it contacts open fire or is under high temperature, it's difficult to burn and be spreading rapidly, and will stop burn after removing the combustion?source. Class B2: Combustible?building?materials: Combustible materials have good flame resistance function. when it contacts open fire or is put in the air at high temperature, it will immediately burst into flames, and easily result in the spreading of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. Class B3: Inflammability building materials, without any flame resisting effects, easy to burn, and has large danger of fire disaster.

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: Can refractory be used as sealing element?

- It can. For example, fiber ceramics can resist high temperature! !

- Q: Why should graphitic refractory materials be used now that graphite can burn?

- In theory, any substance can burn as long as certain temperature is reached. Graphite is turned from diamond under anaerobic condition and at high temperature of 2 000 ~ 3 000 ℃. that is to say, ignition point of graphite (lamellar graphite ) under anaerobic condition will be at least above 3 000 ℃. There are many types of graphite, and their ignition points are also different. Ignition point of pyrolytic graphite is much low. Except for a few cutting-edge areas, fire endurance demand for most areas in daily life (eg. brake pad will add a certain amount of graphite) is under 1000 ℃. Therefore, graphite can be used as refractory material. That is, graphite can both burn and can be used as refractory material, which are not contradictory.

- Q: what needs to be noted when choosing and using blast furnace fireproof materials?

- Hello,: three parts of the blast furnace lining in general are easily corroded. The first one is furnace bosh,second is the middle part of the furnace, The third is lower part of the furnace stack. if These parts are damaged, then we need an overhaul. Bosh, because damage to the middle part of the furnace and the furnace bosh are generally due to alkali metal and fusant erosion. the main reason for the lower furnace part damage is molten iron, slag. In view of this situation, mullite bricks, corundum bricks, silicon carbide bricks are used for reparation. make repairments as soon as possible if any problems occur in case of incidents.

- Q: what is the Specifications Grading for Fireproof rubber insulation materials ?

- External insulation materials, welded wire mesh matt external wall insulation, external wall thermal insulation mesh matt. 1,inorganic activel thermal insulation materials 2,silicate?thermal?insulation?material 3,ceramic thermal insulation 4, gelatine powder polyphenyl granule, 5,teel wire gauze picking cement cystosepiment(Estazolam platepowder particles)6 extruded sheetXPX. 7,Rigid polyurethane coating at the scene, Polyurethane insulation board8,rigid polyurethane foam,9EPS foam board roofing materials. 1, a ceramic insulation board 2, xps extrusion board 3, perlite and perlite brick 4, vermiculite and vermiculite brick heating, air conditioning Material: Phenolic resins, polyurethane waterproof thermal insulation integration, sponge rubber, polyethylene, polystyrene foam, glass wool, rock wool Steel material: Polystyrene, extruded sheet, polyurethane panels, glass wool carpets and the like. Five inorganic thermal insulation materials: Foam cement, DY inorganic active insulation system super thin vacuum insulated panel for building external walls .

- Q: How long is the fire endurance of fire resistant rolling shutter door?

- According to fire endurance, fire doors can be divided into Class A, Class B and Class C fire doors, whose fire resistance should be no less than 1.20h, 0.90h and 0.60h respectively. You can use fire resisting shutters to seperate fire?compartments in places where it is difficult to set firewalls. When using the fire resisting shutter with unexposed surface temperature rise as fire endurance conditions, its fire endurance should be no less than 3h. But when using the fire resisting shutter without unexposed surface temperature rise as fire endurance conditions, you should set independent protection of closed automatic water spray system at two sides of the shutter, and the duration of water spraying should be no less than 3.0h. I hope it's useful.

- Q: What are the grades of refractory exterior wall thermal insulation materials?

- Classification of fire rating of extrior thermal insulation materials 1, According to national standard GB8624-97, the combustion performance of building materials are divided into the following grades A level: Incombustible building materials: Materials hardly burn. B1 class: Flame-retardant building materials: Flame-retardant material has good flame resistance. In case of fire in the air or at high temperature, it is difficult to catch fire and the fire will not spread quickly. And when the combustion source is removed, the burning will stop immediately. B2 Class: Combustible building materials: Combustible materials have a certain flame retardancy. In case of fire in the air or at high temperature, it will immediately burst into flames and it is easily to spread fire, such as wooden column, wooden roof truss, wooden beams and wooden stairs, etc. B3 level: Inflammable building materials: It has no flame retardant effect, and it is extremely inflammable, and the risk of fire is high. Classification of exterior wall thermal insulation materials according to fire rating: 1. Thermal insulation materials with A-level combustion performance Rock wool, glass wool, foam glass, foamed ceramic, foam cement, hole-closed perlite, etc. 2, Thermal insulation materials with B1-level combustion performance: Extruded polystyrene board (XPS) after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polystyrene granule, and etc. 3. Thermal insulation materials with B2-level combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for Refractory:High Density Silica Brick 95B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords