Ceramic Fiber Bulk - Refractory Ceramic Fiber Bulk Buy from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Bulk HighTemperature Resistance Refractory Insulating

Ceramic fiber friction material is made from standard ceramic fiber blown bulk through shear, slag removal processes, and secondary processing, as one of ideal raw material for production of friction materials . As the crucial and staple materials for producing ceramic fiber blanket, board, module and other formed products, Hitex ceramic bulk fiber is normally manufactured from high purity raw materials-alumina powder, silica sand through unique production techniques of spun or blowing, these bulks are loose, long and flexible with fine thermal properties, at present, the chopped fibers for vacuum formed production, the lubricated bulk fibers and the fiber for textiles are all available. Hitex ceramic bulk fibers serve as an ideal filler for various types of refractory lining and insualtion tools.

Main Product Features:

1.Low heat storage and thermal conductivity.

2.Excellent chemical and thermal stability.

3.Contains no bonding agent ad corrosive substance.

4.Thermal shock resistance and acoustic absorption.

5.Asbestos free and flexible applications.

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

1. Staple materials for other ceramic fiber products.

2. Expansion media.

3. Mouldable feedstock

4. Ladle insulation

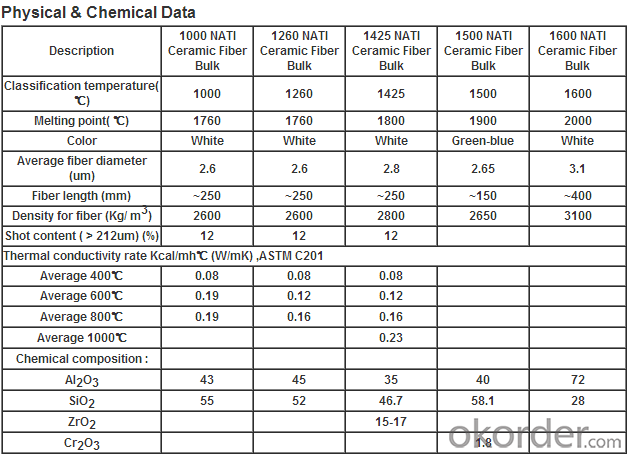

Product Specifications:

FAQ:

1. When can I get the price?

We will try our best to provide you the price within 24 hours after received your inquiry.

2.Can I get samples?

Yes, of course. Free samples will be provide for your testing. The samples will be sent out within 3 days after your confiremation of density, size, qty etc.

3.What about the payment terms?

As for the payments, every payment terms can be negotiable.

Product Picture

Produce Processing

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the miniature furnace chamber, the ceramic fiber furnace can be selected, and once the furnace is formed, the length of the furnace is longer.

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- Ceramic fiber is a short fiber that needs to be reinforced and toughened by other objects. It is generally toughened by glass fiber and stainless steel wire. The high silicon oxygen is long fiber, no need to toughen by other objects. The short-time high silica resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q: Is the ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q: Is aluminum silicate fiber poisonous?

- Ceramic fiber loose cotton is a kind of fluid which can melt high purity clay clinker, alumina powder, silica powder, chrome sand and so on in the industrial electric furnace.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of glass fiber: advantages: good insulation, good heat resistance, good corrosion resistance, high mechanical strength, low water absorption, low price. Disadvantages: brittle, poor wear resistance.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- There is no full ceramic fiber material fire shutter;

Send your message to us

Ceramic Fiber Bulk - Refractory Ceramic Fiber Bulk Buy from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords