recycled Polypropylene Staple Fiber for Geotextile or Toys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

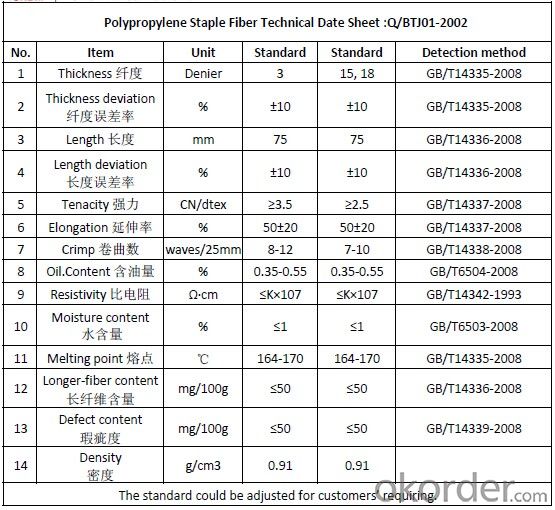

1, PP Staple Fiber

PP staple fiber is characterized with high tenacity and antiflaming, anti-aging,anti-UV,water-repellency can be added to improve its performance.

Specification: 1.5D-110D, 5-150MM. Regular specification includes 3D,4.5D,6D,18D,38MM, 65MM,76MM,102MM etc.

Color: white, black, red, green etc, as per customers requirements.

2, Package of PP Staple fiber

250KG OR 300KG Per bale, wrapped by PP fabric and about 75 bales could be put into 1x40'HQ, allowing more or less clause.

3, Specialities of PP Staple Fiber for Oil Absorption Felt

A:not absorb water

B:acid resistant and alkali resistant

4, Application of PP Staple fiber

A:Geotextile, filing material for toys

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP staple fiber which is used as the raw material of textile, automotive interior etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What about polyester fabric? How about air permeability?

- Polyester fiber generally refers to polyester fiber, fabric quality is the result of comprehensive performance, as outlined below, your question is only the last line to answer, but I think you need to know something:The main physical and chemical properties of polyester fiber1. form: Polyester vertical surface straight, smooth, cross section is round (can be changed to special-shaped, such as triangle, hexagon, etc.). Polyester acid and not alkali, because polyester macromolecules in the ester base in the hydrolysis, but also can use appropriate alkali for polyester silk imitation treatment. (alkali reduction treatment)2., stretch and flexibility: polyester high strength, stretch growth, resilience, good, ordinary polyester strength of 35.2 ~ 52.8cN/tex, breaking elongation rate of 30% to 40%. According to the different processing, polyester has high strength, low extension, low strength, high extension and so on. Because of its high strength, great elasticity and good elasticity, polyester fiber has good wear resistance, which is second only to nylon. In addition, the high modulus polyester fabric, so crisp, good dimensional stability.3. moisture absorption and dyeing: Polyester structure close, high crystallinity, internal macromolecules without hydrophilic gene, so low moisture absorption, dyeing difficult. Polyester in general atmospheric conditions, moisture regain is only 0.4%. Therefore, the fabric has the advantages of easy washing and quick drying, and also reflects the defects of poor sweat absorption and poor ventilation.

- Q: What do you mean by "T300 T700" in carbon fiber?

- Carbon fiber T number refers to the level of carbon materials, industry refers to Japan's Dongli company produced a certain kind of carbon material, the industry generally refers to the ultra-high precision carbon materials. How many T refers to the cross section area of 1 square centimeters of the number of units of carbon fiber can withstand tension tonnage. So in general, the higher the T number, represents the carbon level is high, the quality is better.

- Q: What are the differences between silk, yarn and fiber three? Where are the differences between decorative fabrics and clothing fabrics?

- Fiber is the most basic unit, such as cotton fiber / fabric, chemical fiber and so on. Silk generally refers to continuous fibers, such as silk / nylon yarn / polyester fiber, etc.. A yarn is a twisted filament or yarn, the cord is a continuous cord made of several yarns, with the highest tensile strength.

- Q: What's the acid and alkaline difference between wool and cellulose fiber?

- Wool is not alkaline, ah, caustic soda water can dissolve the wool, the general situation of PH can not exceed 11., but the wool acid resistance, the general concentration of sulfuric acid is not a problem

- Q: Structural performance difference between polyacrylonitrile and carbon fiber

- The chain structures undergo cyclization and crosslinking during the pre oxidation stage to form a heat-resistant ladder structure. The carbon phase is conjugated to form the carbon base surface during the carbonization stage, and the carbon base surface grows up and finally forms a graphite like structure.

- Q: What is the difference between microfiber fabric and modal fabric? What is the use?

- Now, mostly used in the production of underwear, knitted fabrics, mainly used for the production of underwear. But the modal has a silver sheen, excellent dyeability and dyeing characteristics of bright color, would be used to coat. Because of this, the modal becomes the coat and decorative cloth material.

- Q: What are man-made fibers? What are his strengths and weaknesses?

- One of the two major types of chemical fibers. Some natural polymers or their derivatives are used as raw materials, and then they are made into textile solutions. Then they are spun into fibers. Bamboo, wood, bagasse, cottonseed and so on are all raw materials for making man-made fibers. According to the shape and use of artificial fiber, it is divided into three kinds: rayon, artificial cotton and synthetic wool. Important varieties are viscose fiber, acetate fiber, copper ammonia fiber and so on.

- Q: Which is better, carbon fiber or glass fiber reinforced plastic?

- Carbon fiber has many excellent properties, carbon fiber axial strength and high modulus, low density, high performance, no creep, non oxidation under the environment of high temperature resistance, good fatigue resistance, between heat and electrical conductivity between the metal and non metal, smaller thermal expansion coefficient and anisotropy, good corrosion resistance, X Radiability good. Good conductivity, thermal conductivity, good electromagnetic shielding, etc..

- Q: What is nonwoven fiber?

- Textile made from textile fibers and processed by adhesion, fusion, or other chemical or mechanical methods. This textile is not the traditional spinning, weaving or knitting process, also known as non-woven fabrics, non-woven fabrics.

- Q: What is the difference between regenerated fibers and Lesel fibers?

- The development of regenerated cellulose fiber can be divided into three stages on the whole, forming the three generation products. The first generation was the ordinary viscose fiber, which was released in the early twentieth Century to solve the cotton shortage. The second generation was started in 1950s to realize industrialized production of high wet modulus viscose fiber, its main products include Japan R & D toramomen (named Polynosic) and the change of American R & D high wet modulus fiber HWM and Lenzing Co in late 80s by the new process of production of Modal fiber. In late 60s, due to the rapid development of synthetic fiber production technology, low cost and adequate sources of raw materials, synthetic fibers have greatly affected the market position of regenerated cellulose fiber. Many research institutions and enterprises to pay more attention to the development and application of new synthetic fiber. During this period, the development of regenerated cellulose fibers in the world tended to be stagnant. Third generation products are introduced in 1990s staple fiber Tencel (Tencel), filament Newcell as a representative. Influenced by the awareness of health and environmental protection, nature and other factors, people have a new understanding of the physicochemical properties of regenerated cellulose fiber, a new generation of regenerated cellulose fibers has been fully improved, therefore, the application of regenerated cellulose fibers of the re emergence of rapid development.

Send your message to us

recycled Polypropylene Staple Fiber for Geotextile or Toys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords