Raw Materials for Refractory - 97 Silicon Carbide90/Recrystallized Silicon Carbide/SiC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

97 Silicon Carbide90/Recrystallized Silicon Carbide/SIC

1.Structure of Silicon Carbide Description

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

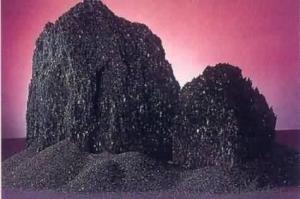

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Specifiction | SiC | F.C | Fe2O3 | Moisture |

SiC 86 | 86%min | 2.4%max | 2.0%max | 0.2%max |

SiC 88 | 88%min | 2.3%max | 2.0%max | 0.2%max |

SiC 90 | 90%min | 2.0%max | 1.8%max | 0.2%max |

SiC 92 | 92%min | 1.8%max | 1.7%max | 0.2%max |

SiC 93 | 93%min | 1.8%max | 1.6%max | 0.2%max |

SiC 95 | 95%min | 1.0%max | 1.3%max | 0.2%max |

SiC 97 | 97%min | 0.8%max | 1.2%max | 0.2%max |

SiC 97.5 | 97.5%min | 0.8%max | 0.9%max | 0.2%max |

SiC 98 | 98%min | 0.5%max | 0.5%max | 0.2%max |

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: What are the use of fire-resistant material and admixture?

- Generally speaking, there are several admixtures: 1. Water reducing agent. It can ensure basic refractory castable flow value and significantly reduce its water mixing amount sodium hexametaphosphate and sodium tripolyphosphate 2. Plasticizer. It can increase plastic refractory mixture and enhance the ability of bentonite clay mud material stress strain 3. Gelling agent. It can make the colloidal solution (or suspending liquid containing solid particles condensed gelling agent 4. Dispergator. It can turn condensation or reunion colloidal particles (particles) into sol or uniform dispersion suspended particles and make the thick colloid free stream sol said scattered coagulant peptizer 5. Coagulant. It can shorten the stereotypes refractories condense sclerosis NaOH Mars between aluminum hydroxide, etc. 6. Retarder. It can delay the stereotypes refractories condense sclerosis between citric acid tartaric acid, etc. 7. Delayed coagulant. It can make setting fire-resistant materials contain binder by set out the condensation hardening effect between calcium aluminate cement, etc. 8. Foaming agent. It can reduce the liquid surface of power to produce uniform stability as rosin soap bubble resin fat saponin and so on. 9. Antifoaming agent. It can make fast setting fire-resistant material mixing or shock in produce bubbles escape alcohol fatty acids, such as 10. Shrink agent can reduce or prevent the refractory materials used to produce contraction type heating said silicon powder stabilizer or volume expansion agent, etc. 11. Preservative. It can keep setting fire-resistant material stored on construction performance change or change oxalic acid citric acid, etc. 12. Inhibitors. It can inhibit stereotypes refractories ingredients contain iron or iron compounds and acidic reaction caused inflation to produce hydrogen bond CrO3 diacetone alcohol, etc. I hope it can help you.

- Q: How long is the fire-fighting time of A class fire resisting window?

- Duration of fire resistance of fire resisting window: A class window is not less than 1.2 hours; B class window is not less than 0.9 hours and C class window is not less than 0.6 hours. Technical Requirements: 1materials and accessories (1) window frame structure adopts stell framework and wooden framework that have a certain strength to ensure integrity and stability. (2) steel framework and batten can choose galvanized steel plate or stainless steel The selection criteria meet requirements of GB12955 steel fire door general technical conditions in the provisions of article 5.1. The selection criteria of wooden framework and batten meet requirements of GB14101 wooden fire door general technical conditions in the provisions of article 5.1.1. Filling material of steel and wooden framework shouldn't adopt non-combustibility material. (5) fire-fighting glass can adopt testing-qualified product that don't influence fire resistance performance of fire resisting window. Light transmittance of glass is not less than 75% of the same layer common plate glass. (6) Sealing material between framework and fire-fighting glass should adopt Flame retardant material which can serve as fire-fighting and smoke-resistant when encounter fire disaster. (7) hardware fitting should accessories product that is tested to be qualified. 二. installation requirement: 1. When Party A takes over goods, he should check numbers, specification, grades and whether Accessories are Conformed and complete according to contract.

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: What refractories have good mechanical property resistance and heat expansion and cold contraction property?

- Explain that where you use it for and what requirements you have. Follow-up: I use it in metallurgical furnaces with the features of strong stirring and acidic residue.

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: Does anyone know about the classification standards of B2-level fireproof and thermal insulation materials?

- The classification standards of B2-level fireproof and thermal insulation materials: 1. the national standard GB8624-97 classifies construction materials combustion performances into several grades, B2-level: combustible building materials: combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. 2.The exterior wall thermal insulation materials can be classified according to fire rating, insulation materials with B2-level combustion performance are: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: What are the fireproofing materials of the external wall included?

- Facades a fireproof material comprises three anti-cloth, fireproof cloth, plastic cloth, PVC tarpaulins, flame retardant cloth, Hair Dryers cloth, automobile tarpaulin, PVC three anti-cloth, the freight yard covered cloth, PVC coated fabric, canvas industry etc., are widely used in automobile canopy cover cloth, trains cover cloth, ships cover cloth, cloth covered open-air yard, industrial and agricultural fields; used in glass, timber, fertilizer plants, steel plants, machinery metal factory, feed mill, grain storage, container plants, oil refineries, packaging plants, paper plants, air conditioning plants, logistics, ore factory, fleet, rail, sea and so hoping to help you

- Q: What are the new refractories?

- Most are ordinary refractories.

- Q: What are the advantages of refractory material?

- Jingute WHL type, GDS type

Send your message to us

Raw Materials for Refractory - 97 Silicon Carbide90/Recrystallized Silicon Carbide/SiC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords