Q235 Color Steel Step Tile Roll Forming Machine with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

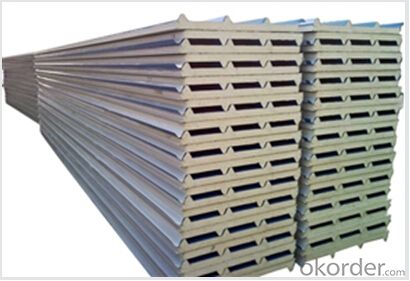

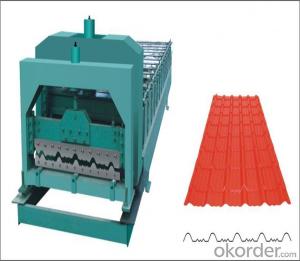

Step Tile Roll forming machine

Technical data of step tile roll forming machine

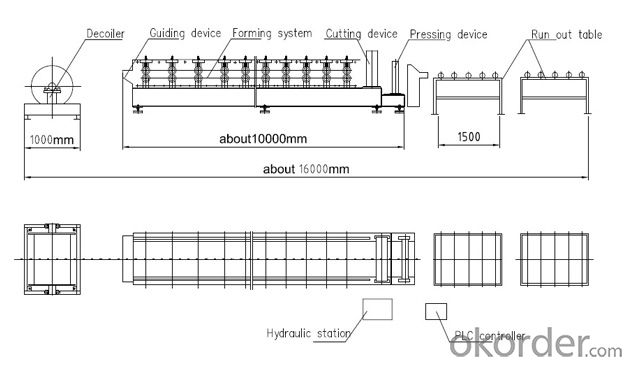

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

Size of machine installation | About 18m×1.8m× 1.5m (Depend on final design) | |

Layout drawing of machine

Our Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q: The Function of Machine Tool Body in CNC Machine Tool

- 1. Machine base pieces: refers to the bed, base, column, slide, table and so on.

- Q: What is the lathe?

- 1. Carefully study and understand in detail the interrelationships between parts, components, mechanisms, and relationships between the various lathes.

- Q: What is the meaning of CNC machining?

- Decoding, so that the machine to implement the provisions of a good action, through the cutting of the blank material into semi-finished finished parts.

- Q: What can a CNC lathe do?

- 1 to 2 years on the almost a little advanced machine tools on the master's ability and technical requirements are high.

- Q: What is the meaning of R in the data lathe?

- The meaning of other letters in CNC lathes:

- Q: CNC lathes 6140 and 6040 What is the difference

- 7 for multi-knit and profiled lathes, 8 for wheels, shafts, spindles, rollers and shovel lathes, and 9 for other lathes.

- Q: CNC machine tools and general machine tools in the detection of the biggest difference between the machine

- Ordinary machine tools because it is hand-processing so it is difficult to ensure the consistency of mass production.

- Q: What is the main work of CNC machine tools?

- CNC machine tools are the main equipment of mechanical processing, compared with ordinary machine tools is a high-performance automated machine tools, with the following obvious features:

- Q: Who can tell me the difference between instrument lathe and CNC lathe

- X, Z axis of the servo motor to control the lathe feed movement of the action sequence, the amount of movement and feed speed, coupled with the spindle speed steering, and automatic tool change system, enabling the processing of different shapes of different shaft

- Q: What tools (machines) are required for lathe processing?

- Lathe processing is generally required to prepare the chuck, wrench, top, drill, turning, caliper, micrometer, dial indicator and so on.

Send your message to us

Q235 Color Steel Step Tile Roll Forming Machine with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords