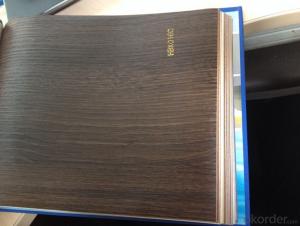

PVC Wood Grain Plastic Sheets Decorative and Matte Surface Film HBF

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Importing modern equipment and skill to produce PVC pattern decoration material and PVC hardship.have a wide selection of design

1.Specifications

Pvc Film

1. Having own mould room

2. Guaranteed quality

3. Fast delivery

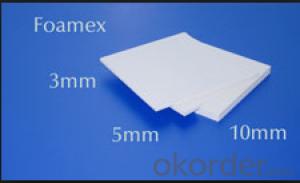

Specification: | Thickness:within 0.08mm to 0.60mm (according to customer's request) |

Width: within 670mm to 1450mm (according to customer's request) | |

Length: The MOQ is 2000 meters each color each size | |

Packing: | About 100m to 400m per roll (according to customer's request) |

Packing rolls with polyfoam in carton or pallet (according to customer's request) | |

Delivery time: | About 15-20 days after received the deposit |

Payment item: | 30% as deposit by T/T,the balance against B/L |

Shipping: | Any port in Foshan/Guangdong |

Others | Special requests on color matching and new designs creation are available. |

Features: | Exquisite color, distinct pattern, environmentally friendly, durable, waterproof, fireproof, unfading, anti-erosion, antirust, smooth surface, reasonable shrinkage ratio and no need to paint |

Main material: | PVC |

Applications: | Mainly used as decorative cover material for audio boxes, gift boxes, plywood, wooden doors, steel-panel doors, furniture and indoor decorations. |

Processing Mode: | Hot lamination,cold lamination,vacuum molding etc. |

Below sizes are our existing sizes, and custom sizes are accepted.

Size(MM) | Thickness(MM) | Packed | 20ft container |

1260 | 0.12 | 100m/400m | 90000m |

1260 | 0.16 | 100m/400m | 86000m |

1260 | 0.18 | 100m/350m | 85000m |

1260 | 0.20 | 100m/350m | 70000m |

1260 | 0.25 | 100m/250m | 70000m |

1260 | 0.30 | 100m/150m | 35000m |

1260 | 0.35 | 100m/150m | 35000m |

1260 | 0.40 | 100m/150m | 32000m |

1260 | 0.45 | 100m/150m | 30000m |

1260 | 0.50 | 100m/150m | 25000m |

1400 | 0.18 | 100m/300m | 50000-55000m |

1400 | 0.20 | 100m/300m | 45000-40000m |

1400 | 0.25 | 100m/250m | 40000-45000m |

1400 | 0.30 | 100m/150m | 30000m |

1400 | 0.35 | 100m/150m | 30000m |

1400 | 0.40 | 100m/150m | 25000-27000m |

1400 | 0.45 | 100m/150m | 25000m |

1400 | 0.50 | 100m/150m | 20000m |

- Q: So I went to staples and had them laminate like 8 papers I HAVE to have laminated by tomorrow.... And I picked them up, came home, and they were literally my papers stuck between 2 plastic sheets. I can peel it easily and it is not sticking at all. Am I supposed to do something or did they mess up and forget something???? Please help!!!!

- It sounds like they messed up. My guess is that the machine was not hot enough to allow the laminate sheeting to bond. Yes, you should call them and go back. Laminating IS two plastic sheets with a paper between. However, when the machine is very hot, the plastic softens and bonds. Did you trim the papers? You should always leave a narrow edge of plastic around the edges, perhaps a quarter inch. If you trim it exactly against the paper, there is nothing on the edge to seal and bond. If they did the trimming, then check the edging. If there is a quarter edge beyond the paper and it is separating, then take it back. That could be a machine not hot enough. Take your receipt.

- Q: How can the stains on the plastic steam plate be removed?

- Finally, you can use the diluted disinfectant to brush the place where it has not been soaked. Rinse it with clean water.This way we can rest assured that the use of 84 disinfectant can not only make plastic chopping board cleaner and more transparent, can also play the role of disinfection, but also on the plastic chopping board does not produce corrosion. In addition, the price of disinfectant is very cheap, and the water can be washed into the toilet for cleaning.

- Q: I want to build a faster oven for drying plastic sheets. I currently us an 8'x8' low temp gas oven but need to dry more material faster. I've seen info on a woodworker that built a Microwave dryer for large wood projects and wonder if the same technology can be used to dry plastic. A major concern of course is containing the microwave radiation. I'm open to any safe ideas.

- It can be done, and done safely, although microwaves might not be the best source of energy for that particular application. Radio frequency energy might be a better choice. Unfortunately, this forum isn't really the best place for a detailed discussion. Click the source link below and feel free to make contact.

- Q: Any cheap alternatives to the plastic stencil sheets?

- Masonite is too thick to work with. If you're doing street art, you still kind of want to be able to draw like you can with an exacto. Plastic sheeting is good if you want to be able to reuse a stencil. It also rolls up. But cheap poster board works just as well, except that it can fold, which you don't want. You can always go back and cut the plastic stencil from the poster. If you're dead set on the plastic, but can only find 8.5x11, just use clear scotch tape to match the edges. Just make sure the cut outs don't sever the whole seam. Poster board will tear, so let paint dry before you lay them down, and lift them off the painting surface before they dry

- Q: Are plastic sheets resistant to fading?

- Yes, plastic sheets are generally resistant to fading.

- Q: Lets say person A buys 2 tabs of acid, puts it in a plastic baggy, and inserts in pocket. Is there any chance of the lsd bleeding through the plastic and being absorbed into person A's leg?

- No, there is far too little LSD to be absorbed. Plus plastic barrier will act as a barrier.

- Q: Can plastic sheets be used for protective barriers?

- Yes, plastic sheets can be used for protective barriers. They are often used as a cost-effective and versatile solution to protect against physical, chemical, or biological hazards. Plastic sheets can offer transparent visibility, resistance to impact, and easy installation, making them suitable for various applications such as in healthcare settings, construction sites, or industrial environments.

- Q: Are plastic sheets scratch-resistant?

- Yes, plastic sheets can be scratch-resistant depending on their composition and manufacturing process. Some types of plastics, such as polycarbonate or acrylic, are specifically designed to have scratch-resistant properties. However, it is important to note that not all plastic sheets are scratch-resistant, so it is necessary to choose the right type of plastic sheet for specific requirements.

- Q: Can plastic sheets be used for electrical enclosures?

- Yes, plastic sheets can be used for electrical enclosures. Plastic materials such as polycarbonate or ABS can provide insulation, protection, and durability for electrical components, making them suitable for enclosures. However, it is important to choose the right type of plastic sheet that meets the necessary electrical safety requirements and provides adequate protection against environmental elements.

- Q: I'm using it to make a model, so I only need a small sheet, nothing industrial in scale. A place to buy it near downtown LA would be optimal. From what I've found, the material is known as corrugated plastic or hollow board in some places.

- Some where between 25 30 I stopped looking forward to an age.

Send your message to us

PVC Wood Grain Plastic Sheets Decorative and Matte Surface Film HBF

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords