PVC Foam Board Plastic Processing Machinery for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.Processing performance:

1. plastic coating, membrance-stuck and printing

2. with the usual equipment and tools, it can be processed again.

3. welding and bonding

4. cutting and sawing

5. bending when heated-up, thermal forming

6. hole-drilling, Channeling and die cutting

7. nail, wrest and rivet

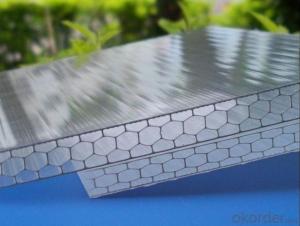

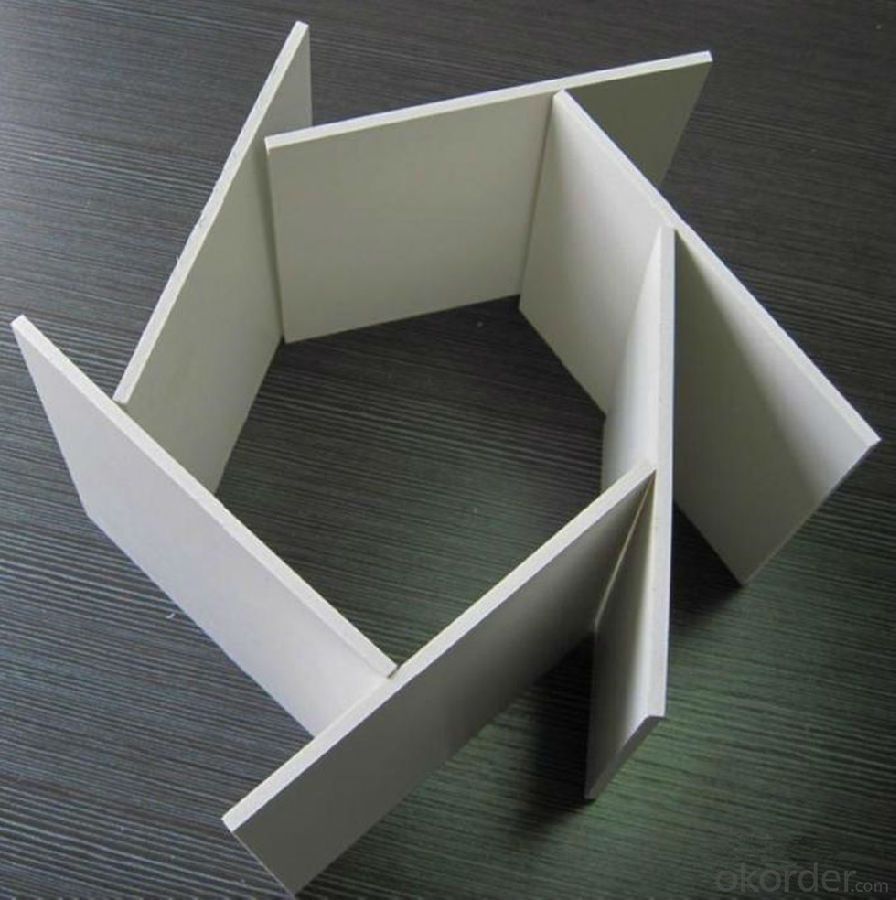

6.Products Pictures

7.Pictures of Factory

- Q: Are plastic sheets resistant to cracking or splitting?

- Yes, plastic sheets are generally resistant to cracking or splitting.

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing.

- Q: im currently decorating one of the bedrooms of the house im living in, and have set my self on having a big stencil design, roughly abut 6 ft x 4 ft but i need a sheet of plastic to be able to make the stencil, any ideas as to where i could find something like this?

- This Site Might Help You. RE: where can i find a big sheet of clear plastic for making stencils? im currently decorating one of the bedrooms of the house im living in, and have set my self on having a big stencil design, roughly abut 6 ft x 4 ft but i need a sheet of plastic to be able to make the stencil, any ideas as to where i could find something like this?

- Q: AKA: The Dark Ages.

- You could also refer to it as the When we had a spine era.

- Q: I'm looking to get my hands on some sheets of kydex to use for making my own custom gun holsters (or attempt to make some). I'd rather not have to order them off the web. I live in northern indiana and haven't been able to find anything around but my search hasn't gone on to long. If any body knows anything that would be great.

- Buy Kydex Sheets

- Q: Moved into a house that has a small bathroom with 4'x8' sheets of tile installed. (Not real ceramic tile, I think plastic?) Can these be painted?

- Anything can be painted, as long as you use the correct paint. You'll need to do a little research to find out what material the tile is made of, and then go to any paint store and ask for the right paint for that material. Some prep work might be needed, like sanding the surface to make the paint adhere, but the store rep should be able to help you with advice if they have any intelligence for that department. ;)

- Q: I'm quite tired of writing in a notebook and having the pages underneath hold the impression of what I wrote. I've seen these this plastic sheets that stop it but I'm not sure what they would be called. Any ideas?--Andriana

- Just take the underneath pages out...

- Q: Hi! where can I buy an expanded PVC sheet (foam) or a corrugated Polyethylene or Polypropylene plastic sheet in the Philippines. I need like roof panel sizes.

- hardware yard best place to try but these sheets are available from local manufacturers. Look on the net

- Q: How do you clean plastic sheets?

- To clean plastic sheets, you can start by wiping them down with a damp cloth or sponge using mild soap or a gentle household cleaner. Avoid using abrasive materials or harsh chemicals that could damage the plastic. Rinse off the soap residue thoroughly and then dry the sheets with a clean cloth or allow them to air dry.

- Q: Indoor ceiling plastic how to clean up the most convenient and concise?

- Sponge mop dipped in detergent water, clean up two times.The ceiling is dirty dust and smoke stains, once the water is quickly dissolved, and the plastic buckle resistance, easy cleaning.

Send your message to us

PVC Foam Board Plastic Processing Machinery for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords