Baseball Packaging Tape with PVC Electrical Tape Embossed Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape with Embossed Printing

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape with Embossed Printing

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape with Embossed Printing

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape with Embossed Printing

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

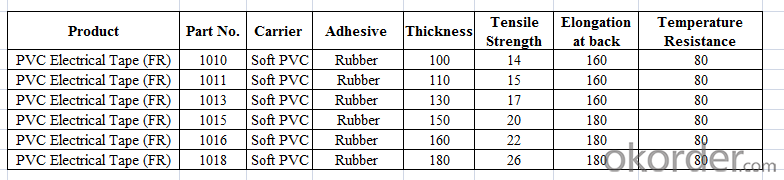

Technical Data of PVC Electrical Tape with Embossed Printing

Product Show of PVC Electrical Tape with Embossed Printing

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape heat resistant?

- Yes, packaging tape is generally heat resistant. Most packaging tapes are made from materials such as polypropylene or acrylic, which have high melting points and are able to withstand high temperatures. This heat resistance makes packaging tape suitable for various applications, including sealing boxes and packages that may be subjected to heat during transportation or storage. However, it is important to note that the specific heat resistance of packaging tape may vary depending on the brand and quality of the tape. Therefore, it is recommended to check the product specifications or consult with the manufacturer to ensure that the packaging tape is suitable for the intended use and temperature conditions.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Indeed, bubble wrap can be effectively sealed with packaging tape. The purpose of packaging tape is to establish a robust and secure seal on diverse materials, bubble wrap included. In the packaging and shipping sectors, it is widely employed to guarantee the safety and security of package contents throughout transportation. To ensure optimal protection and prevent any potential harm or exposure, it is essential to apply the tape along the edges of the bubble wrap, creating a snug seal.

- Q: Is packaging tape transparent?

- Yes, packaging tape can be transparent. Many types of packaging tape are made from clear materials such as polypropylene or acrylic, allowing them to be see-through. This transparency is beneficial as it allows users to easily see the contents of a package without having to open it. Additionally, transparent packaging tape is often preferred in situations where a clean and professional appearance is desired, as it blends in well with various types of packaging materials. However, it is important to note that not all packaging tapes are transparent, as there are also colored or printed options available for specific purposes or branding needs.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: How does packaging tape adhere to surfaces?

- Packaging tape adheres to surfaces through the use of adhesive materials. The adhesive on packaging tape is typically made from a synthetic rubber or acrylic-based material. These materials are designed to have a strong bonding ability to various surfaces such as cardboard, plastic, or metal. The adhesive on packaging tape works by creating a bond between the tape and the surface it is applied to. When pressure is applied to the tape, the adhesive material spreads and makes contact with the surface. This contact allows the adhesive to interact with the surface's molecules, creating a bond through intermolecular forces. The most common type of adhesive used on packaging tape is pressure-sensitive adhesive (PSA). PSA is designed to stick to surfaces with the application of light pressure. When pressure is applied, the adhesive material flows and conforms to the surface, creating a strong bond. The adhesive on packaging tape is also designed to be resistant to various environmental factors such as temperature, humidity, and moisture. This ensures that the tape remains securely adhered to the surface even under challenging conditions. In summary, packaging tape adheres to surfaces through the use of adhesive materials, typically synthetic rubber or acrylic-based. These adhesives create a bond between the tape and the surface through intermolecular forces, allowing the tape to stick securely.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages has several benefits. Firstly, it helps to ensure the safety of the package contents and the individuals handling them. The warning messages act as a visual reminder of any potential hazards or special handling instructions, reducing the risk of accidents or mishandling. Secondly, it saves time and effort by eliminating the need for separate warning labels or writing instructions on the packaging. The pre-printed tape provides a clear and professional warning message that can be easily recognized by anyone involved in the packaging process. Lastly, it enhances the overall professionalism and branding of the company. The customized warning messages on the tape can include the company's logo, contact information, or any other branding elements, making the package stand out and leaving a positive impression on the recipient.

- Q: What's the problem of sealing the tape off?

- Also on the production process of the knife edge, workers do not pay attention to knives, slitting, occasionally also have knife edge, is not common. Also, the tape is too thin, no strength reasons. And then there's the quality problem. The tape is two...................

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: Can packaging tape be used for sealing glass or delicate items?

- Yes, packaging tape can be used for sealing glass or delicate items. However, it is important to use caution and choose the appropriate tape for the job. When sealing glass or delicate items, it is recommended to use a tape that is specifically designed for these materials. Clear or transparent packaging tape is often a good option as it provides a secure seal without obstructing the view of the item. Additionally, it is important to apply the tape carefully and evenly to avoid any damage to the fragile surface. Overall, while packaging tape can be used for sealing glass or delicate items, it is crucial to select the right type of tape and apply it with caution to ensure the safety of the items being sealed.

- Q: Can packaging tape be used for sealing pharmaceutical or medical supplies?

- Yes, packaging tape can be used for sealing pharmaceutical or medical supplies. However, it is important to ensure that the tape is compatible with the specific requirements of the supplies and adheres securely to maintain proper hygiene and prevent contamination.

Send your message to us

Baseball Packaging Tape with PVC Electrical Tape Embossed Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches