Visy Packaging Tape PVC Electrical Insulation Tape Smooth Safety Barricade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

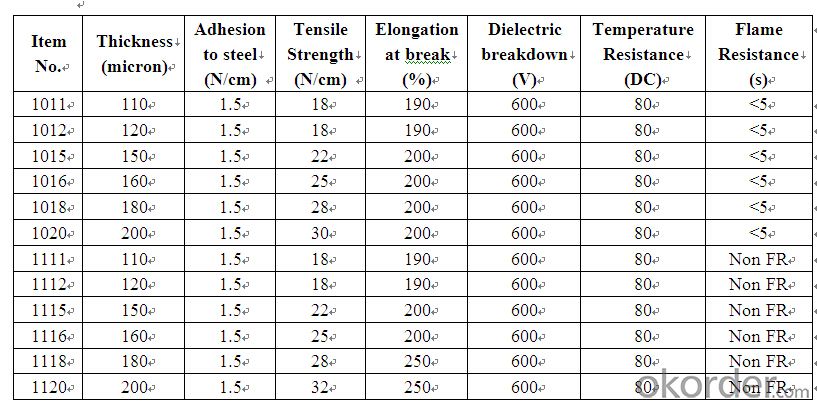

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Is packaging tape resistant to extreme pressure or weight?

- The purpose of packaging tape is to secure packages with a strong and reliable seal. However, the ability of the tape to withstand extreme pressure or weight can differ depending on its type and quality. Typically, packaging tapes are crafted from resilient materials such as polypropylene or polyester, enabling them to endure typical handling and transportation pressures. Nevertheless, it should be noted that packaging tape might not withstand excessively heavy loads or excessive pressure. In such instances, it is suggested to enhance the tape's strength by adding extra layers or employing heavy-duty tapes that are explicitly designed for high-pressure or weight-bearing purposes.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers. Packaging tape is designed to securely seal boxes and packages, and it provides a strong adhesive bond. When applied properly, it can effectively seal the openings of plastic pet carriers, ensuring that your pet is safely contained inside. However, it is important to ensure that the tape is applied evenly and securely to prevent any gaps or openings that your pet may be able to escape from. Additionally, it is recommended to check the tape periodically to make sure it remains intact and reapply if necessary.

- Q: Can packaging tape be used for labeling?

- No, packaging tape is not typically used for labeling as it is primarily used for securing packages and boxes during shipment.

- Q: Can packaging tape be used for sealing glass jars?

- Yes, packaging tape can be used for sealing glass jars. It provides a strong and secure seal, ensuring the contents remain fresh and protected. However, it is important to note that specialized jar sealants or methods, such as canning lids or rubber seals, may be more suitable for long-term storage or preserving purposes.

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience. Packaging tape is available in various lengths to meet the needs of different packaging tasks. The most common lengths of packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are designed to cater to different packaging needs and ensure that there is enough tape to securely seal multiple packages without running out. Additionally, the availability of different lengths allows for flexibility in choosing the most suitable amount of tape for specific packaging requirements, ensuring convenience and cost-effectiveness.

- Q: Is packaging tape safe to use on stainless steel?

- Certainly! Packaging tape poses no harm to stainless steel and can be safely used. Generally, packaging tape is manufactured using non-corrosive materials that do not harm the surface of stainless steel. Nevertheless, it is advisable to conduct a patch test on a small and inconspicuous area of the stainless steel before applying the tape to the entire surface, particularly if the tape will remain in place for an extended duration. Moreover, removing the tape cautiously and gradually can aid in averting any possible damage or residue on the stainless steel.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q: Can packaging tape be used for sealing packages with heavy items?

- Certainly, one can utilize packaging tape to seal packages that contain bulky items. Packaging tape is purposely crafted to offer robust stickiness and sturdiness, thus rendering it ideal for securing packages that carry weighty contents. It is manufactured from resilient materials such as polypropylene or acrylic, guaranteeing its ability to endure the weight and pressure of substantial items without tearing or becoming loose with ease. Furthermore, packaging tape frequently possesses a formidable adhesive backing that adheres well to different surfaces, thus ensuring a reliable seal. Nonetheless, it is imperative to select the fitting width and thickness of packaging tape in order to ensure proper sealing for packages with heavy contents.

- Q: Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. It is a commonly used method to secure and seal plastic containers, ensuring their contents remain intact and protected.

- Q: Is packaging tape easy to write on?

- Packaging tape is not particularly easy to write on. The smooth and glossy surface of the tape makes it challenging for most writing tools to adhere properly. Regular pens or markers may smudge or fade quickly, resulting in illegible writing. Additionally, the adhesive nature of packaging tape can cause ink to bleed, making it difficult to achieve clean and precise writing. Therefore, if you need to write on packaging tape, it is advisable to use a permanent marker or a specialized pen designed for writing on non-porous surfaces like plastic. These writing tools typically provide better results and ensure that your writing remains visible and intact.

Send your message to us

Visy Packaging Tape PVC Electrical Insulation Tape Smooth Safety Barricade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords