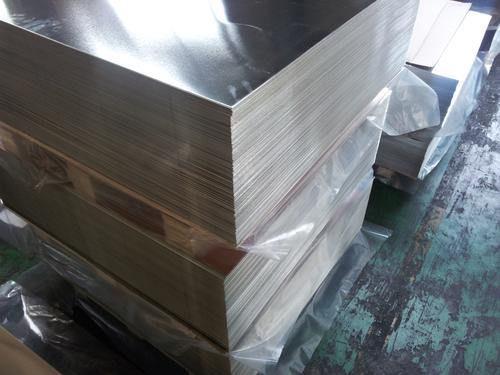

Prime Quality ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate is widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

- Q: What are the main applications of tinplate in the construction industry?

- Tinplate is commonly used in the construction industry for the production of roofing materials, such as tin roofs, due to its durability, corrosion resistance, and ability to withstand extreme weather conditions. It is also utilized for manufacturing gutters, downspouts, and flashings, providing protection against water damage. Additionally, tinplate is employed in the construction of HVAC systems, air ducts, and ventilation pipes, as it provides a reliable barrier against moisture and corrosion.

- Q: What are the advantages of using tinplate?

- Some of the advantages of using tinplate include its high strength and durability, excellent corrosion resistance, and its ability to be easily formed and shaped. Tinplate also provides a barrier against oxygen, moisture, and light, making it ideal for packaging food and beverages. Additionally, tinplate is recyclable, making it a sustainable choice for packaging materials.

- Q: What printing methods are used on tinplate?

- The commonly used printing methods on tinplate include lithography, offset printing, and screen printing.

- Q: Can tinplate be used for packaging of hazardous materials?

- Yes, tinplate can be used for packaging of hazardous materials. Tinplate is known for its high corrosion resistance, durability, and ability to withstand extreme temperatures. These properties make it suitable for packaging materials that may pose a risk to human health or the environment. Additionally, tinplate can be coated or lined with appropriate materials to provide an extra layer of protection and prevent any leakage or interaction between the hazardous material and the packaging.

- Q: Can tinplate be customized with embossing or debossing?

- Yes, tinplate can be customized with embossing or debossing techniques.

- Q: What are the advantages of using tinplate for packaging?

- There are several advantages of using tinplate for packaging. Firstly, tinplate is highly durable and can withstand external impacts, protecting the contents of the package. Secondly, it is resistant to corrosion, ensuring the longevity of the packaging and preventing contamination of the product. Additionally, tinplate is lightweight and easy to handle, reducing transportation costs and making it convenient for consumers. Moreover, tinplate is environmentally friendly as it is 100% recyclable, promoting sustainability and reducing waste. Lastly, tinplate offers excellent printing capabilities, allowing for attractive designs and branding options, which can enhance product visibility and appeal.

- Q: Tin can weldingHow can the side of the column of the pop top be welded or pressed?,

- Mainly divided into the tank, the tank cover and the tank bottom three parts. The tank body is made of a piece of iron material through the curl bending machine, by using copper welder and welding. Now the mainstream of aerosol cans, food cans and beverage cans are produced by this method.

- Q: How does tinplate perform in terms of odor resistance?

- Tinplate generally demonstrates good odor resistance due to its non-reactive nature and protective tin coating, which helps prevent any unwanted odors from permeating the material or affecting the contents stored inside.

- Q: What are the main challenges in tinplate manufacturing?

- Some of the main challenges in tinplate manufacturing include ensuring consistent quality of the tin coating, maintaining precise thickness and uniformity of the tinplate, managing the handling and storage of the tinplate to prevent damage or contamination, and addressing environmental concerns related to the tin coating process and waste disposal. Additionally, the industry faces the challenge of meeting customer demands for cost-effective production while adhering to strict regulatory standards and keeping up with technological advancements.

- Q: What are the different surface finishes available for tinplate?

- The different surface finishes available for tinplate include bright, stone, matte, and silver.

Send your message to us

Prime Quality ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords