Prime C45 Carbon Steel Round Bar Used for Machinery Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime C45 Carbon Steel Round Bar Used for Machinery Components

Product Description of Prime C45 Carbon Steel Round Bar Used for Machinery Components

1. Steel grade: SAE1045, 45#, C45, S45C

2. Length: 6M-12M

3. Diameter: 16mm-300mm

4. Product range: round bar, flat bar, square bar

5. Technique: Hot rolled, forged, cold drawn

Specification of Prime C45 Carbon Steel Round Bar Used for Machinery Components

Material | C45 | 16-300mm | ||

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12m | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500mm |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200mm | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12m |

Chemical Composition of Prime C45 Carbon Steel Round Bar Used for Machinery Components

C | Si | Mn | Cr | Ni | Cu |

0.40~0.49 | 0.17~0.37 | 0.35~0.65 | ≤0.25 | ≤0.30 | ≤0.25 |

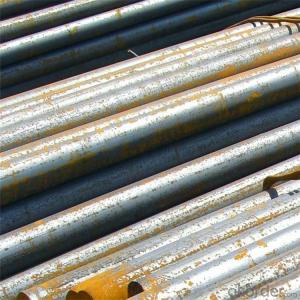

Photo Show of Prime C45 Carbon Steel Round Bar Used for Machinery Components

Packing and Delivery:

Packing in bundle package, or as customer's requirements.

Delivery Detail: 45 days after receiving the deposit.

Usage and Applications of Prime C45 Carbon Steel Round Bar Used for Machinery Components

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some special material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel round bars be used for structural purposes?

- Yes, steel round bars can be used for structural purposes. They are commonly used in the construction industry for various applications, such as providing support and reinforcement in buildings, bridges, and other structures. The high strength and durability of steel make round bars an ideal choice for structural use, as they can withstand heavy loads and provide stability.

- Q: Can steel round bars be used for shafts or axles?

- Yes, steel round bars can be used for shafts or axles. Steel round bars are commonly used in various industries, including automotive, machinery, and construction, for their strength, durability, and versatility. They are often chosen for shafts or axles due to their ability to withstand heavy loads, provide reliable support, and resist wear and tear. Steel round bars can be machined and heat-treated to meet specific requirements, making them suitable for use as shafts or axles in various applications where strength and reliability are crucial, such as in vehicles, industrial equipment, and rotating machinery.

- Q: Can steel round bars be polished?

- Yes, steel round bars can be polished. Polishing steel round bars involves using abrasive materials, such as sandpaper or polishing compounds, to remove any imperfections or rough surfaces on the bar's surface. This process can be done by hand or with the help of machinery specifically designed for polishing metals. The end result is a smooth and shiny surface on the steel round bar. However, it is important to note that the type of steel and the desired finish will determine the specific polishing techniques and materials required.

- Q: What are the different marking methods for steel round bars?

- Steel round bars commonly use several marking methods to identify and provide information about the bars. These methods include stamping, laser marking, inkjet printing, etching, and color coding. Stamping involves using a machine to imprint alphanumeric characters, symbols, or logos onto the steel bar's surface. This method provides a durable and corrosion-resistant marking. Laser marking, on the other hand, uses a laser beam to engrave precise and high-quality information onto the bar. It allows for intricate designs, barcodes, and serial numbers and ensures permanent identification. Inkjet printing is a non-contact method that prints information using inkjet technology. It is commonly used for barcodes, QR codes, and other data matrix codes. This method is fast and efficient, with ink that adheres effectively to the steel surface. Etching is a chemical method that removes layers of the steel's surface using acid or other chemicals. It creates a visible mark and is often used for logos and identification numbers. Etching provides a permanent and easily readable marking. Color coding is a simple method that uses paint or colored coatings to mark different steel grades. Each color represents a specific attribute or characteristic. Color coding allows for quick and visual identification of the bars. These marking methods are essential in industries like construction, manufacturing, and engineering as they ensure proper identification, traceability, and quality control of steel round bars. The choice of method depends on factors such as permanence, visibility, and the specific information to be marked on the bars.

- Q: Are steel round bars suitable for use in food processing equipment?

- Steel round bars are not suitable for use in food processing equipment. This is because food processing equipment necessitates materials that can resist corrosion, are easy to clean, and do not react with food substances. Although steel round bars are strong and durable, they have a tendency to rust and can potentially contaminate food with metallic particles. On the other hand, stainless steel is the ideal choice for food processing equipment due to its high resistance to corrosion, ease of cleaning, and non-reactive properties. It is crucial to prioritize the safety and hygiene of food processing equipment, which is why steel round bars should not be utilized in this context.

- Q: Are steel round bars suitable for the production of springs?

- Indeed, springs can be produced using steel round bars. Steel, renowned for its exceptional strength and durability, finds widespread application in spring manufacturing. The circular configuration of these bars facilitates effortless shaping and molding, rendering them an ideal choice for spring production procedures. Steel round bars can be conveniently machined and heat-treated to impart the desired spring attributes, including elasticity and resilience. Furthermore, steel boasts a remarkable tensile strength, enabling it to endure substantial loads. Consequently, it proves well-suited for applications necessitating robust and dependable springs.

- Q: What is the difference between a hot-rolled and a peeled steel round bar?

- The main difference between a hot-rolled and a peeled steel round bar lies in their manufacturing processes. A hot-rolled steel round bar is formed by heating a metal billet or ingot to a high temperature and then rolling it into its final shape and size. This process results in a rougher surface texture and a larger diameter tolerance. On the other hand, a peeled steel round bar undergoes an additional step called peeling after the hot-rolling process. In this step, the outer surface of the bar is removed by rotating it against a stationary cutting tool. This process improves the surface finish and dimensional accuracy of the round bar, resulting in a smoother and more precise product. In summary, while both hot-rolled and peeled steel round bars are commonly used in various industries, the peeled bar offers superior surface finish and dimensional accuracy due to the additional peeling step in its manufacturing process.

- Q: What are the different types of steel round bar finishes?

- There are several different types of steel round bar finishes, including hot rolled, cold drawn, turned and polished, and ground and polished.

- Q: What are the different types of steel round bar shapes?

- There is a wide range of steel round bar shapes to choose from, each possessing its own distinctive characteristics and uses. Some commonly seen types include: 1. Round: This shape is the most commonly used and versatile for steel round bars. It takes on a cylindrical form and finds application in various industries like construction, manufacturing, and automotive. 2. Square: Square steel round bars feature four equal sides and are often employed when a robust and sturdy form is needed. They are frequently utilized in construction, architectural designs, and machinery. 3. Hexagonal: Hexagonal steel round bars boast six sides, setting them apart with their unique shape. They are often selected for applications requiring high strength and corrosion resistance, such as aerospace, defense, and oil and gas industries. 4. Flat: Flat steel round bars exhibit a rectangular cross-section with flat top and bottom surfaces. They are commonly used when a broad, level surface is desired, as in construction, machinery, and manufacturing sectors. 5. Half Round: Half-round steel round bars adopt a semicircular shape with a flat base. They are frequently employed for handrails, fencing, and decorative purposes. 6. D-shaped: D-shaped steel round bars possess a flat bottom surface and a curved top surface, resembling the letter "D". They are often favored when a sturdy yet lightweight structure is required, such as in automotive frames and chassis. These examples merely scratch the surface of the various steel round bar shapes available. The choice of shape hinges upon the specific requirements of the application, encompassing factors like strength, durability, corrosion resistance, and aesthetic appeal.

- Q: What are the different types of steel round bar surface treatments for improved wear resistance?

- Some common types of steel round bar surface treatments for improved wear resistance include heat treatment, such as carburizing or nitriding, which introduces a hardened layer on the surface of the bar. Other options include coating the surface with materials like chrome or nickel to enhance durability. Additionally, shot peening is a process that bombards the surface with small metallic or ceramic particles to create compressive stress and improve resistance to wear.

Send your message to us

Prime C45 Carbon Steel Round Bar Used for Machinery Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords