Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

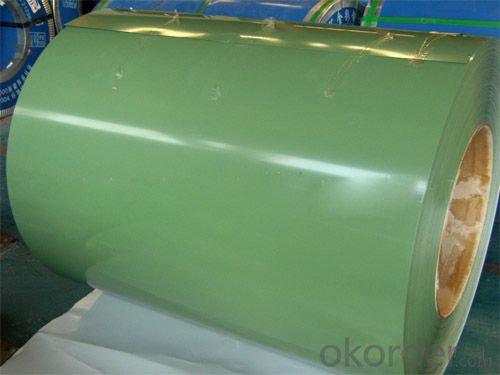

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can the steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding. Steel is a ferromagnetic material, which means it can effectively redirect and absorb magnetic fields. When steel sheets are used to shield against magnetic fields, they create a barrier that helps to prevent the penetration of magnetic flux into a designated area. This property makes steel sheets an excellent choice for applications where magnetic shielding is required, such as in electronics, medical devices, and sensitive laboratory equipment. However, the effectiveness of steel sheets for magnetic shielding can depend on various factors, including the thickness and composition of the steel, as well as the strength and frequency of the magnetic field being shielded. Therefore, it is important to consider these factors and consult with experts to ensure the appropriate steel sheets are selected for optimal magnetic shielding.

- Q: What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as sheet thickness, size, shape, and the specific steel material used. It is typically determined by conducting engineering calculations and considering local building codes and standards. Therefore, it is not possible to provide a specific average wind load capacity without knowing the specific details of the steel sheets in question.

- Q: Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel is a commonly used material in the automotive industry due to its strength and durability. It can provide the necessary support and stability required for suspension components to withstand various driving conditions and loads.

- Q: Can steel sheets be used for furniture manufacturing?

- Certainly, furniture manufacturing can utilize steel sheets. Steel, being a versatile and durable material, lends itself well to shaping and forming into various furniture components, including table legs, frames, and shelves. The strength, stability, and sleek appearance of steel sheets make them a commonly chosen option for producing modern and industrial-style furniture. Moreover, steel offers easy customization through welding, bending, or cutting, enabling the creation of personalized furniture designs. By incorporating steel sheets, furniture manufacturers gain advantages such as resistance to corrosion, fire, and pests. Consequently, steel sheets have become a favored choice among furniture manufacturers aiming to craft contemporary, sturdy, and enduring furniture pieces.

- Q: What is the difference between a hot rolled and cold rolled stainless steel sheet?

- The manufacturing process and resulting properties distinguish hot rolled stainless steel sheets from cold rolled ones. Hot rolled sheets are created by heating stainless steel to a high temperature and rolling it through a series of rollers to achieve the desired thickness. This method is typically used for larger sheets and results in a rougher surface finish. Additionally, hot rolled sheets are known for their inherent strength and malleability, making them suitable for various applications that require structural integrity. In contrast, cold rolled stainless steel sheets are produced by cooling the stainless steel to a lower temperature and passing it through rollers at room temperature. This process yields a smoother and more refined surface finish compared to hot rolled sheets. Cold rolled sheets are commonly preferred for precision-demanding applications such as automotive components, appliances, and electronic devices. Regarding mechanical properties, hot rolled stainless steel sheets generally possess a higher yield strength and lower ductility when compared to cold rolled sheets. This can be attributed to the grain structure formed during the hot rolling process, resulting in a more coarse and less uniform microstructure. Conversely, cold rolled sheets have a finer grain structure and higher ductility, making them more suitable for forming and bending operations. To summarize, the primary differences between hot rolled and cold rolled stainless steel sheets lie in the manufacturing process and the resulting properties. Hot rolled sheets exhibit a rougher surface finish, higher strength, and lower ductility, whereas cold rolled sheets possess a smoother surface finish, higher ductility, and are often preferred for precision-demanding and forming applications.

- Q: What is the tensile strength of the steel sheets?

- The tensile strength of steel sheets can vary depending on the specific grade and thickness of the steel. Generally, steel sheets have a tensile strength ranging from 370 to 1,500 megapascals (MPa). However, it is important to note that different types of steel sheets have different tensile strength values. For example, low carbon steel sheets typically have a tensile strength of around 370 to 550 MPa, while high-strength low alloy (HSLA) steel sheets can have tensile strengths ranging from 450 to 1,200 MPa. Additionally, the thickness of the steel sheets can also affect their tensile strength, with thicker sheets generally having higher tensile strength values. Therefore, it is crucial to consult the specifications provided by the manufacturer or supplier of the steel sheets to determine the precise tensile strength for a particular grade and thickness.

- Q: What are the different finishes available for steel sheets?

- Some of the different finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: How do you calculate the weight of a steel sheet?

- To calculate the weight of a steel sheet, you need to know its dimensions (length, width, and thickness) and the density of the specific type of steel being used. The weight can be calculated by multiplying the volume (length x width x thickness) by the density.

- Q: Is the pattern steel plate hot-dip galvanized steel?

- Hot galvanized steel sheet is hot-dip coated with a metal sheet of zinc about 5-12 microns in size. It is corrosion resistant.The pattern board is a steel plate with a pattern on its surface. The English name is diamond plate. The pattern of a lentil shaped, diamond, round bean shaped, oval shape mixed on the market, the most common form of lentils. Pattern board, according to the material (aluminum alloy, stainless steel, ordinary steel, etc.) different, different shape patterns.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet refers to a stainless steel sheet that has been coated with a protective layer or finish, which could be a polymer or another material. This coating serves to enhance the sheet's resistance to corrosion, scratches, and other forms of damage. The coating also provides a decorative or aesthetic appeal, as it can come in different colors or textures. On the other hand, an uncoated stainless steel sheet refers to a stainless steel sheet that does not have any additional protective layer or finish. It is in its natural state, with its inherent properties and characteristics. Uncoated stainless steel sheets are known for their high resistance to corrosion, durability, and strength. They are commonly used in applications where their natural properties are sufficient to withstand the intended environment. The main difference between coated and uncoated stainless steel sheets lies in their protective properties and appearance. Coated stainless steel sheets offer an extra layer of protection against corrosion and damage, making them suitable for environments where there is a higher risk of exposure to harsh conditions or corrosive substances. They also provide a wider range of design options due to their variety of coatings. Uncoated stainless steel sheets, on the other hand, are preferred in applications where the natural properties of stainless steel are sufficient to meet the requirements. They are often used in architectural and structural applications, as well as in industries such as food processing, pharmaceuticals, and medical equipment, where hygiene and durability are essential. In summary, the difference between a coated and uncoated stainless steel sheet lies in the additional protective layer and aesthetic options offered by the coating. Coated stainless steel sheets provide enhanced resistance to corrosion and damage, as well as a wider range of design choices, while uncoated stainless steel sheets rely on their inherent properties for durability and strength. The choice between the two depends on the specific application and the desired balance between protection, aesthetics, and cost.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords