Wrench for Plastic Pipe Fittings - PPR Reducing Coupling Reduction External/Internal

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: PP-R

Technics: injection

Type: Coupling

Place of Origin: China (Mainland)

Model Number: DS-001

- Connection: Welding

Shape: Reducing

Head Code: round

color: green/ grey/ white

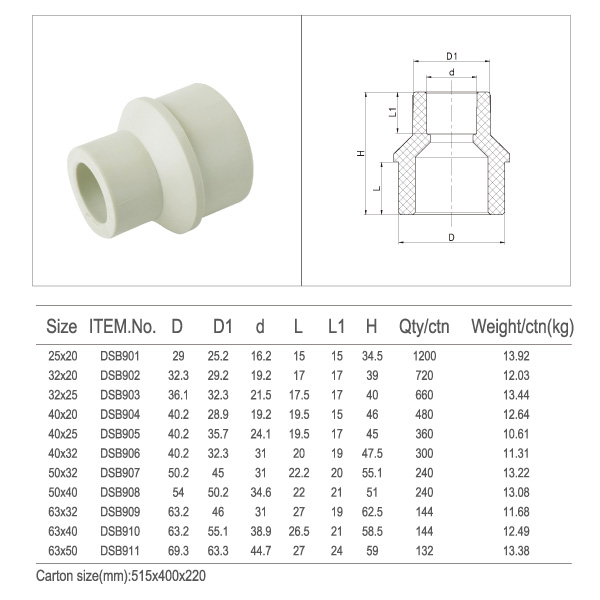

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~63

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag and carton

Delivery Detail: 10 Days

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q: How do plastic pipe fittings compare to cast iron fittings?

- Plastic pipe fittings are generally lighter, more affordable, and easier to install compared to cast iron fittings. They are also resistant to corrosion, which makes them a popular choice for plumbing systems. On the other hand, cast iron fittings are known for their durability and strength, making them suitable for high-pressure applications or areas with heavy traffic. Ultimately, the choice between plastic and cast iron fittings depends on the specific needs and requirements of the plumbing project.

- Q: Can plastic pipe fittings be used in fish farming systems?

- Yes, plastic pipe fittings can be used in fish farming systems. Plastic fittings are commonly used in aquaculture due to their durability, chemical resistance, and affordability. They are suitable for various applications, such as water supply, drainage, aeration, and filtration systems in fish farming operations.

- Q: What are the common connecting methods for plastic PP pipes?

- Because the hot melt connection method does not need any additional material, and can melt the connection part as a whole, achieves the body strength, the connection effect is good, therefore, here recommends the use of hot melt connection method. The use of hot-melt bonding method should pay attention to the following: first, the hot melt tool to connect the power supply, to the working temperature, the indicator light before the start of operation; II. Cutting the pipe material, you must make the surface perpendicular to the pipe axis. The general use of pipe cutting scissors or pipe cutting machine, using sharp hacksaw when necessary, but after cutting the pipe section should remove burrs; the PP pipe and pipe connection end must be clean, dry and free of grease; the welding elbow or three pass, according to the requirements of design drawings, we should pay attention to its direction in a straight direction pipe and tube, mark the location with the auxiliary mark the connection, no rotation; the end of the guide tube heating sleeve is inserted into the standard depth, at the same time, no rotating the pipe onto the heating head and reached the prescribed mark; the heating time is reached after, immediately put the pipe and pipe fittings from the heating sleeve and the heating head removed simultaneously, quickly and without rotation inserted into the standard depth, making joints form a uniform flange of the joint can be corrected, but not the rotation; to a prescribed cooling time, will The pipe cover is buckled on the pipe fittings.

- Q: Are plastic pipe fittings resistant to UV radiation?

- Yes, plastic pipe fittings are generally resistant to UV radiation. Most plastic materials used in pipe fittings, such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), contain additives that provide UV resistance. These additives help protect the fittings from the harmful effects of prolonged exposure to sunlight and prevent them from becoming brittle or degrading over time.

- Q: Are plastic pipe fittings resistant to moisture?

- Yes, plastic pipe fittings are generally resistant to moisture.

- Q: Can plastic pipe fittings be used in drainage systems?

- Yes, plastic pipe fittings can be used in drainage systems. Plastic fittings, such as PVC or ABS, are commonly used in drainage systems due to their durability, resistance to corrosion, and ease of installation. They are available in a variety of sizes, shapes, and angles to accommodate different drainage configurations.

- Q: Are plastic pipe fittings compatible with compression fittings?

- Yes, plastic pipe fittings can be compatible with compression fittings. However, it is crucial to ensure that the specific type of plastic pipe and compression fitting are designed to work together. It is recommended to consult the manufacturer's instructions or seek professional advice to ensure proper compatibility and installation.

- Q: Are plastic pipe fittings suitable for water supply lines?

- Yes, plastic pipe fittings are suitable for water supply lines. They are commonly used in residential and commercial plumbing systems due to their durability, affordability, and resistance to corrosion. Plastic pipe fittings are also easy to install and maintain, making them a popular choice for water supply applications.

- Q: Can plastic pipe fittings be easily installed?

- Yes, plastic pipe fittings can be easily installed. They are lightweight, flexible, and typically require simple tools and techniques for installation. Additionally, plastic pipe fittings often come with clear instructions and are designed to be user-friendly, making the installation process relatively straightforward for both professionals and DIY enthusiasts.

- Q: Are plastic pipe fittings resistant to impact?

- Yes, plastic pipe fittings are generally resistant to impact due to their durable and flexible nature.

Send your message to us

Wrench for Plastic Pipe Fittings - PPR Reducing Coupling Reduction External/Internal

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords