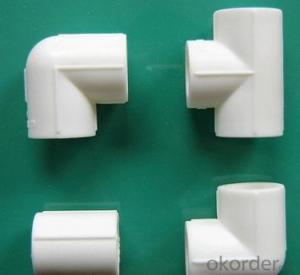

15mm PPR Elbows for Industrial and Agricultural Fields Plastic Water Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Advantanges

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

1. Can you find a translator for me?

You can tell us which language you speak, we will find the translator for you, and will be together work.

2. If we want to develop some new item, but maybe we just have some ideas, how can you do?

We can make new mold base on your idea, generally, if your quantity is more enough, we can refund the mold cost to you.

3. How Long Is Delivery?

Delivery time will be 30-45 days according to order quantity.

4.What Is Our Normal Payments Terms?

Our normal payment terms: T/T, L/C or western union

- Q: Are plastic pipe fittings as durable as metal pipe fittings?

- Plastic pipe fittings are generally not as durable as metal pipe fittings. While they can be more affordable and resistant to corrosion, plastic fittings are more susceptible to cracking, breaking, and degradation over time. Metal pipe fittings, on the other hand, offer greater strength, longevity, and resistance to physical damage.

- Q: Can plastic pipe fittings be used in fire alarm systems?

- No, plastic pipe fittings cannot be used in fire alarm systems. Fire alarm systems require materials that are capable of withstanding high temperatures and are fire-resistant.

- Q: Can plastic pipe fittings be used for vacuum systems?

- Yes, plastic pipe fittings can be used for vacuum systems as long as they are specifically designed and rated for that purpose. It is important to choose fittings that can handle the required level of vacuum pressure to ensure safety and optimal performance of the system.

- Q: What are the connecting modes of steel wire mesh and plastic composite pipe?

- The connection of wire mesh frame and plastic composite pipe is made up of two kinds of electric heating welding and flange connection. Electric melting connection is a composite pipe socket to electrofusion fittings, make embedded electric heat wire on the surface of the heat pipe fitting.

- Q: Are plastic pipe fittings suitable for HVAC systems?

- Yes, plastic pipe fittings are suitable for HVAC systems. They are lightweight, durable, and corrosion-resistant, making them an excellent choice for both residential and commercial HVAC applications. Additionally, plastic fittings are easy to install, cost-effective, and provide leak-free connections, which is essential for maintaining the efficiency and reliability of HVAC systems.

- Q: What are the specifications of PVC tubes?

- There are many kinds of PVC tubes. I saw them on the PVC plastic web. This is the website of PVC industry. There are the latest PVC tube information. Go in and have a look.

- Q: PSP plastic steel composite pressure pipe has several ways of connecting

- With a certain flexibility, it can be bent, so that the flexibility of handling, transportation, installation and reliability of operation. The underground installation can effectively withstand the sudden impact load caused by subsidence, slip and vehicle. The fixed length (12m) single plastic steel composite pipe can be bent 25 degrees one-way, saving the use of small angle turning head.

- Q: Are plastic pipe fittings suitable for chemical injection systems?

- Yes, plastic pipe fittings are suitable for chemical injection systems. Plastic pipe fittings are commonly used in chemical injection systems due to their resistance to corrosion and chemical attack. They provide a reliable and cost-effective solution for transporting chemicals safely and efficiently.

- Q: What are the machines for making plastic plugs?

- Plastic plug production machine: material drawing machine, cold heading machine, injection molding machine, wire rolling machine, CNC lathe, etc..

- Q: How do you connect plastic pipe fittings to PVC pipes?

- To connect plastic pipe fittings to PVC pipes, you can use solvent cement specifically designed for PVC pipes. First, clean the ends of both the plastic pipe fittings and PVC pipes to ensure they are free from dirt and debris. Then, apply the solvent cement to both the pipe fittings and the pipes. Insert the pipe fittings into the PVC pipes, making sure they are aligned properly. Allow the solvent cement to dry as per the manufacturer's instructions. This will create a secure and watertight connection between the plastic pipe fittings and PVC pipes.

Send your message to us

15mm PPR Elbows for Industrial and Agricultural Fields Plastic Water Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords