PP or PET Non woven Polyester Geotextile Used in Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geotextile

Non-woven geotextil price for road

1.CE and ISO

2.elogation ratio:25-100

3.CBR bursting strength :0.3-4.0

Application of Geotextile

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Woven geotextile :

Made from polypropylene and or polyester fibers, manufactured with high tensile strength and low elongation, our woven geotextiles have superior properties for filtration, separation, reinforcement, erosion control and drainage. We are leader in providing woven geotextiles for a variety of civil and environmental applications including highways, port facilities, reservoir, transport construction, waste and chemical management ,subgrade engineering, coast reclamation works, peninsula shoal engineering.

Properties of Multifilament Woven Geotextile

Metric and British conversions:

1kn/m------around68.57lbs/ft 1oz/yd2---around 33.9g/m2 1m------around 3.3ft

Physical properties | Test method | Unit | Typical Value | ||||||||||

Material | Polypropylene/PP | ||||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 | ||

Color | White | ||||||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M >= | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 | ||

Tensile Strength at break CD | ASTM D 4595 | KN/M >= | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 | ||

Elongation at break MD | ASTM D 4595 | % <=< span=""> | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | ||

Elongation at break CD | ASTM D 4595 | % <=< span=""> | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 10.5 | 14 | 18 | 20.5 | 23 | 24 | 28 | ||

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.55 | 1.9 | 2 | 2.2 | 2.3 | 3.2 | ||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||||

Width: max 3.8m, standard 3.6m. Other colors available. | |||||||||||||

Physical properties | Test method | Unit | Typical Value | |||||||

Material | Polyester/PET | |||||||||

Color | White | |||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M | 100 | 150 | 150 | 200 | 400 | 300 | 500 | 1000 |

Tensile Strength at break CD | ASTM D 4595 | KN/M | 50 | 50 | 150 | 50 | 50 | 300 | 100 | 50 |

Elongation at break MD | ASTM D 4595 | % | <=15< span=""> | |||||||

Elongation at break CD | ASTM D 4595 | % | <=15< span=""> | |||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | |||||||

Notes:

1)The property values listed are gained in our laboratories .The right is reserved to make changes without any notice

2)Mechanical properties, origin materials, width, roll length can be adjusted to different applications.

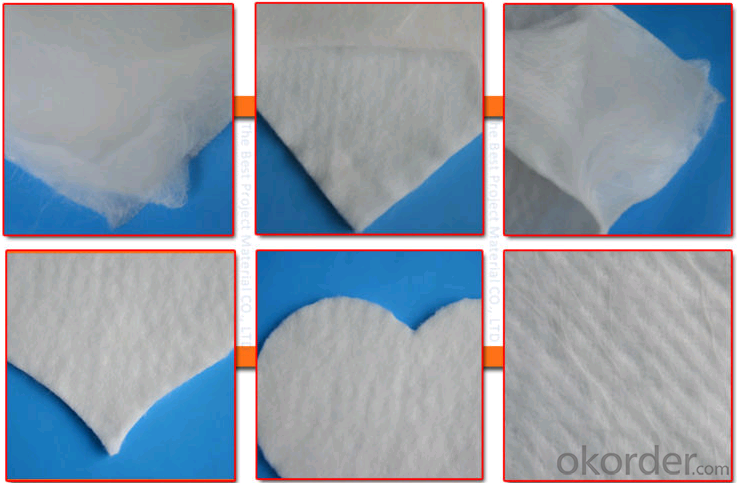

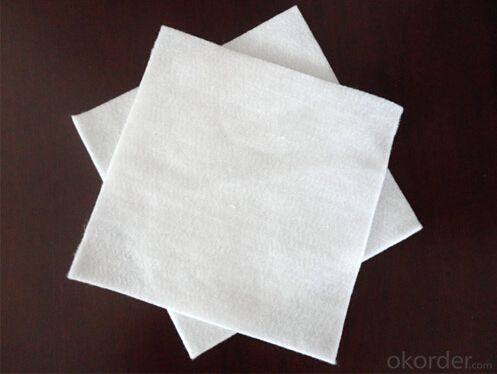

Geotextile Products Show:

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: What are the advantages of modal fabric?

- Modal fabric washing: 1, wash with washing with immersion, soaking time should not exceed 15 minutes, 2 viscose fabric water will harden, the fiber structure is very solid, washing to wash, to avoid pilling or tear; 3, use neutral detergent or low alkali detergent, washing liquid temperature not more than 35 degrees; 4, after washing drainage should fold up the clothes, squeezing out the water a lot, do not wring out of shape, so as to avoid excessive; 5, in the solution after washing, to wash with clean water, use cold water to wash, otherwise there will be a part of solid detergent in the clothes, don't easy to wash down, make the light colored clothes yellow; 6, after washing to avoid exposure of modal fabric maintenance: 1, wear to minimize friction, pull, wash frequently, prevent long wear deformation; 2, washing, drying, ironing clothes, should Stacked smooth, deep and light to open for a long time, hanging in the closet, so as to avoid the elongation deformation; 3, hygroscopic modal is very strong, should avoid high temperature collection, high humidity and mildew phenomenon caused by unclean environment at low temperature; 4, ironing cloth ironing, ironing to use less push and pull the natural extension of clothing.

- Q: What is a composite fabric?

- Composite fabric is a kind of superfine fiber used in special textile processing and unique dyeing and finishing, and then processed by compound equipment. Application of composite fabric "high technology and new materials of new synthetic fiber", with many excellent properties (compared with ordinary synthetic fiber), such as fabric performance, fine clean delicate, elegant, warm, fabric appearance plump, windproof, breathable, waterproof function, fabric warm and good.

- Q: What's the difference between polyester fiber and viscose fabric? Which cost is higher?

- Polyester fiber, commonly known as polyester, polyester, the drawback is airtight, do not sweat, is a lot of clothes, socks, there are ingredients, a cheaper kind.

- Q: What's the difference between knitting cotton and pure cotton?

- Cotton is a use of the yarn bending needle into the circle and string formed fabric, usually has good elasticity, moisture permeability, thermal comfort, children's clothing is the most widely used fabric. However, pure cotton is a fabric made of 100% cotton as raw material. It has better sanitation, warmth retention, moisture absorption and air permeability, and its use of personal clothing is more.

- Q: What is the sanding fabric

- There are many types such as ordinary sanding, sanding, water hair, carbon and water brush, a rubber sanding sanding, such as the common market a few full polyester suede, velvet, cotton velvet, Italy, such as Laikala sanding steel thorn frame fabric, warp knitting various sanding cloth. "Hair" is grinding out with rubber. The whole process is this: impregnating raising agent, drying stentering after sanding machine on the special sanding finishing, sanding machine in Italy, Germany is better, sanding machine has six sand roller, depending on the fabric bag on the different routes of rubber, and rubber cloth in roll speed on and to a certain degree of tension, slowly after rubbing the cloth six sand roller, there is a dense pile fabric. Sanding fabric is cotton fabric by friction sanding machine and diamond rubber, a qualitative change only in the appearance of the species formed. That is to say, while retaining the fabric of the original performance at the same time, the formation of a layer with a downy layer feeling in the fabric surface, gives the fabric a new style at the same time, which not only reduces the thermal conductivity of sanding fabric, added warmth and softness, its color eye-catching, soft, nice outlook. The relative technology of sanding fabric printing fabric is much more complex, after dyeing and finishing, the exquisite sanding process, unique style of odd. A new flower in the textile industry. It feels soft, comfortable, rich in texture, strong sense of drape, easy to care and rich in suede features. It attracts the consumers, and it can be close to each other during use. There is a warm and soft feeling, and the color is as long as new. Due to unique technology, sanding product that will not fade, pilling phenomenon than cotton fabric quality, and weight than the general heavy cotton material.

- Q: Will mulberry silk shrink if it is washed?

- 1, mulberry silk is silk, is one thing. Real silk means "real mulberry silk"2, it will shrink. But shrink degree not to say, is the same as the plain silk habotai, wrinkled little shrinkage than crepe. Chine than Georgette (silk chiffon) small shrinkage rate. Therefore, shrinkage depends on the size of the specific fabric structure.3, in addition to the above, the shrinkage is also related to the size of the printing and dyeing mill processing technology. Loose processing, in the hands of consumers, shrinkage is small; tight processing, to the consumer, shrinkage is large.4, silk and washing fabrics, this cotton cloth with the same washing cloth, has shrunk the water, and no longer shrink.

- Q: What is blended spinning fabric?

- Blended fabric is cotton, chemical fiber and other silk, hemp textile products of natural fiber blended yarn fabric. For example: polyester cotton, polyester wool gabardine etc.. For example, polyester cotton blended fabric is made of polyester fiber, which is made of 65%-67% polyester and 33%-35% cotton blended yarn.

- Q: The suit is good or Hunfang wool acrylic fabric?

- That is usually the "acrylic (J NGL case n)", also called "the synthesis of wool"The main production process of acrylic fiber is polymerization, spinning, preheating, steam drafting, washing, drying, heat setting, curling, cutting and packing.The performance of PAN fiber is very similar to that of wool. When it is stretched 20%, the rebound rate can still be kept 65%, fluffy and curly and soft, and the heat retention is 15% higher than that of wool. It has the name of synthetic wool. The strength is 22.1 to 48.5cN/dtex, 1 to 2.5 times higher than that of wool. Fast performance, outdoor exposure for a year, the strength decreased only 20%, can be made into a curtain, curtain, tarpaulin, gun cover etc.. It can resist acid, oxidant and general organic solvent, but its alkali resistance is poor. The softening temperature is 190~230 degrees.

- Q: What's the difference between garments, textile fabrics, woven fabrics and knitted fabrics?

- The most obvious difference between weaving and knitting is that weaving is made up of warp and weft, so there are two directions of warp and weft. Knitting is made up of a coil, so it has a certain elasticity.

- Q: What's the difference between fabric and lining?

- As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the color and shape of clothing.

Send your message to us

PP or PET Non woven Polyester Geotextile Used in Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches