Binder for Chopped Strand Mat Cwb-914 Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 11200 Kgs kg

- Supply Capability:

- 100000 Kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

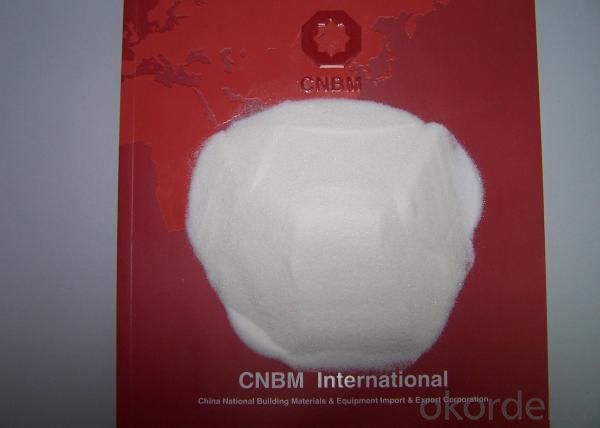

Introduction of Powder Binder for Chopped Strand Mat CWB-914

CWB-914 is binder for fiberglass chopped strand mat and composed of bisphenol A unsaturated polyester resin (nonionic).

CWB-914 imparts to mat good handle and moldability.

Usually CWB-914 is applied directly by spattering the powder through hopper on the traversing chopped strand layer.

Binder content in chopped strand mat is around 3-4%.

Features of Powder Binder for Chopped Strand Mat CWB-914C

WB-914provides soft and flexible properties to the mat with sufficient strength.

CWB-914 is excellent in penetrating effect for the process resins, provides transparency to the finished product and excels in boiling water resistance.

In the course of spattering process at the factory, CWB-914 easily slips down through the hopper on the traversing chopped strand layer below because of its antistatic and free flow features.

CWB-914 can be easily dispersed in water.

Storage of Powder Binder for Chopped Strand Mat CWB-914

CWB-914 should be stored out of sun below 30℃.

Package of Powder Binder for Chopped Strand Mat CWB-914

The binder is to be packed in a plastic bag, then to be put in the carton drum.

Net weight is 140Kg per drum.

The quantity for a 20’ container is 11200KGS.

- Q: What is two-component polyurethane adhesive?

- The amount of the two components can be adjusted in a certain range, generally there is a certain tolerance. The two components of the NCO / OH ratio is greater than or equal to L in general, when the curing time, curing reaction of a part of the NCO group to participate in the production of chemical glue, adhesive force, the excess of the NC0 group in the heat curing, can also produce allophanate, shrinkage of two urea, increase the crosslinking degree, high the adhesive cohesive strength and heat resistance. The solvent-free two-component polyurethane adhesive, because each component of initial molecular weight is generally equal to or slightly greater than NCO / OH molar ratio of L to completely cured, especially in adhesive seal, NCO component can be too much too much. The solvent based two-component adhesive, the main agent of high molecular weight and viscosity of good performance, the two components of the amount can be adjusted in a large range, NCO / OH molar ratio of less than 1 or greater than 1 times. When the NCO component (curing agent) over more occasions, a polyisocyanate adhesive layer is formed from poly tough, adhesive suitable for hard materials; NCO components in less occasions, it can be used for bonding adhesive soft, leather, fabric and other soft materials.

- Q: I'm printing. I'd like to know which kind of printing adhesive Feel better?

- Water based printing adhesives are judged by their hand feel and fastness. Fastness includes washing, dry rubbing, wet rubbing, etc. the hand feel is soft and comfortable, and these indexes are directly related to the adhesive and fabric components,

- Q: An adhesive between upper floors of an asphalt waterproof roll

- PMB-741 elastomer (SBS) modified asphalt waterproof roll

- Q: Silica gel and plastic adhesive, which plastic does not stick?

- Silica gel and plastic binder, commonly known as silicone adhesive plastic glue, this may not be a product can stick all plastic materials, according to different plastic choose silicone adhesive, sticky stick plastic PP/PPSU/PET but with the development of technology now has a relatively good bonding scheme.

- Q: Can sodium humate be used as briquette binder?

- Binder for coal briquette humic acid sodium can be used but not all accessories, huoyun binder for coal briquette adding amount was 0.5%

- Q: Can tile tiles be attached directly to lightweight brick walls?

- Choose the right type of squeegee to ensure that the effective area of the paste is at least 65% of the area of the plate and tile. Use a special toothed scraper to fill the base with 3 to 5 millimeters of thickness, then use a scraper with a toothed side to pull out the stripes in a straight or S shape, and the blade plane and the base plane intersect from 45 degrees to 60 degrees. Tiles do not need to be soaked. Just stick them to the wall / floor in order and press them down. And adjust the tile position within the specified time. Wet cement can be removed with water, but cured only by mechanical means.

- Q: What does the floor tile use adhesive to do?

- The ceramic tile adhesive bonding strength, reduce the chance of delamination and spalling, can guarantee the engineering quality, avoid long-term use after the hollowing and cracking problems, reduce crack opportunities, enhance the protection function of the wall. Add tile paste dry powder mortar hydrophobic redispersible latex powder has the function of anti seepage wall, efflorescence.

- Q: Would you please tell me what the bottom adhesive and adhesive are for a while?

- It is a medium used to bond the surface of homogeneous or heterogeneous objects with continuous stress distribution, light weight, or sealing, and low temperature of most processes. Bonding is especially suitable for different materials, different thickness, ultra-thin specifications and complex components of the connection. Bonding has the fastest development in modern times, the application industry is very wide, and it has a significant impact on the progress of new and advanced science and technology and the improvement of people's daily life.

- Q: What is the binder bricklayer open wall?

- Mainly depends on what kind of brick you buy, and if it is glazed bricks and some other relatively high hardness brick, adhesive is very necessary, but also with wire mesh or copper wire to paste, increase adhesion fastness, prevent brick fall off.

- Q: Ceramic tile adhesive problem, in the ceramic tile adhesive, polyvinyl alcohol can't put more? Why?

- The effect of adding cellulose or polyvinyl alcohol in cement sand is a little different, but basically the same. In general, water can be reduced to a certain extent in order to preserve water and improve flowability. Cement to avoid bleeding phenomenon in solidification process, but also increase the strength of cement.

1. Manufacturer Overview

| Location | Nantong, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 9 Million |

| Main Markets | overseas companies in Thailand, Vietnam, South Korea, India, Singapore, France and many other countries and regions. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10-20% |

| No.of Employees in Trade Department | 3-5 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above6,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Binder for Chopped Strand Mat Cwb-914 Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 11200 Kgs kg

- Supply Capability:

- 100000 Kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords