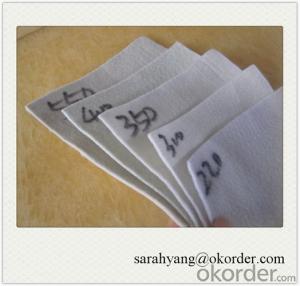

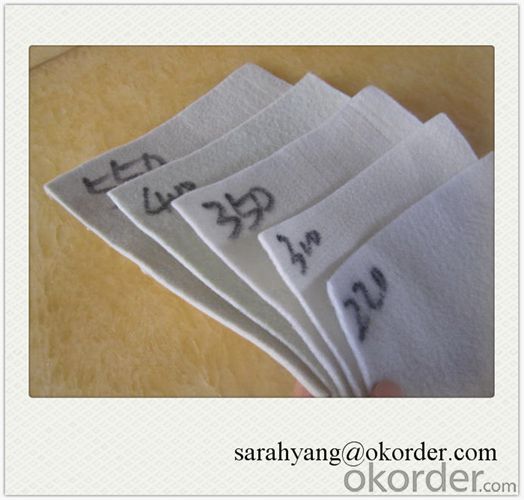

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

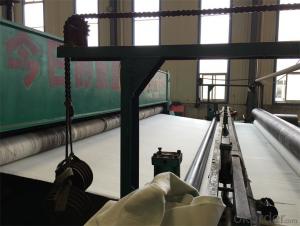

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Use of polyester staple fiber nonwoven fabric with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) in isolation. Make no loss between two or more materials, not mixed, maintains the whole structure and function of material, to reinforce structure load bearing capacity.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles help prevent soil contamination from chemicals by acting as a physical barrier between the contaminated soil and the surrounding environment. These synthetic materials are placed in soil to serve as a protective layer, preventing the migration of chemicals and pollutants. Geotextiles also aid in filtration, allowing water to flow through while trapping and retaining the harmful substances, minimizing their potential impact on the soil and groundwater.

- Q: How do geotextiles contribute to the longevity of geosynthetic clay liners?

- Geotextiles contribute to the longevity of geosynthetic clay liners by providing additional protection and reinforcement. They act as a barrier against punctures and abrasions, reducing the likelihood of damage to the clay liner. Geotextiles also help with filtration and drainage, preventing the buildup of water pressure and ensuring proper functioning of the clay liner. Overall, geotextiles enhance the performance and durability of geosynthetic clay liners, extending their lifespan and effectiveness.

- Q: What are the challenges associated with geotextile installation?

- There are several challenges associated with geotextile installation. One of the main challenges is ensuring proper placement and alignment of the geotextile material. This requires skilled labor and careful handling to prevent wrinkles, folds, or misalignment, which can compromise the effectiveness of the geotextile. Additionally, securing the geotextile in place can be difficult, especially in areas with high winds or water flow. Adequate anchoring and fastening methods need to be employed to prevent movement or displacement of the geotextile. Another challenge is the potential for damage during installation, such as tearing or puncturing the material. This can occur due to equipment, sharp objects, or improper handling. Finally, ensuring proper overlap and seam integrity is crucial to maintain the continuity and strength of the geotextile system. Overall, geotextile installation requires careful planning, skilled labor, and attention to detail to overcome these challenges and achieve the desired performance.

- Q: How do geotextiles help with soil separation in subgrade improvement projects?

- Geotextiles are used in subgrade improvement projects to separate different soil layers, preventing them from mixing. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This helps to maintain the stability and strength of the subgrade, reducing the risk of settlement and soil erosion.

- Q: Where the detection of geotextiles more authoritative

- To the authority must find the authority of the body, the international authority was undoubtedly SGS, geotextile common test such as area weight, tear strength, puncture strength.

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Is still using such a backward technology?

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- The key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and grade of geotextile based on site conditions, ensuring proper placement and anchoring of the geotextile to provide effective soil stabilization, assessing the potential for liquefaction and designing appropriate measures to mitigate it, considering dynamic forces and ground motion during installation, and conducting regular inspections and monitoring to ensure the geotextile's performance and effectiveness in withstanding seismic events.

- Q: Are geotextiles resistant to hydrostatic pressure?

- Yes, geotextiles are generally resistant to hydrostatic pressure. They are designed to have high tensile strength and durability, which allows them to withstand the pressure exerted by liquids or water.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can be used for reinforcement of underground tunnels. Geotextiles are commonly used in civil engineering projects, including tunnel construction, to provide reinforcement, drainage, and separation. In the case of underground tunnels, geotextiles can be installed to prevent soil erosion, provide stability, and enhance the overall structural integrity of the tunnel.

Send your message to us

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords