Propex Polypropylene Filament Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

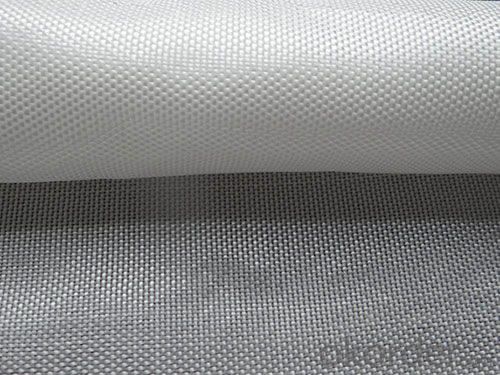

Polypropylene Woven Geotextile

Polypropylene Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Polypropylene Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Polypropylene Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Polypropylene Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

Polypropylene Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Can geotextiles be used in green roof applications?

- Yes, geotextiles can be used in green roof applications. Geotextiles are commonly used as a protective layer between the green roof components and the underlying waterproofing membrane. They provide filtration, separation, and reinforcement functions, helping to maintain the stability and longevity of the green roof system.

- Q: Can geotextiles be used in underground applications?

- Yes, geotextiles can be used in underground applications. They are commonly used in various underground projects such as drainage systems, embankments, roadways, and retaining walls. Geotextiles help to control soil erosion, enhance soil stability, and provide filtration and separation functions, making them suitable for underground applications.

- Q: What is the difference between geotextile and impervious geotextile, geotextile and impervious geotextile?

- Geotextile play filter, filter, the role of reinforcement, with water permeability! Anti-seepage geotextile is generally made of geotextile and geomembrane compound, known as composite geomembrane, or simply as impervious geotextile, you can search for geotechnical materials Pan Huijie consultation to understand. Or user name consultation.

- Q: Can geotextiles be used in erosion control in stormwater detention ponds?

- Yes, geotextiles can be used in erosion control in stormwater detention ponds. Geotextiles are commonly used to stabilize and reinforce soil, prevent erosion, and filter water in various construction and environmental applications, including stormwater management. By placing geotextiles on the slopes and bottoms of stormwater detention ponds, they can help prevent soil erosion caused by the flow of stormwater, reduce sedimentation, and improve the overall effectiveness of the pond in controlling and managing stormwater runoff.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can help reduce soil settlement by providing reinforcement and stabilization. They act as a barrier that distributes the load from structures evenly, preventing differential settlement. Additionally, geotextiles improve soil drainage, allowing excess water to flow through while retaining the soil particles, which further aids in minimizing settlement.

- Q: How do geotextiles help in filtration of stormwater?

- Geotextiles help in filtration of stormwater by acting as a physical barrier that allows water to pass through while trapping sediment, debris, and pollutants. They prevent these contaminants from entering water bodies, improving water quality and reducing the risk of flooding.

- Q: Are geotextiles resistant to hydrocarbons?

- Yes, geotextiles are generally resistant to hydrocarbons.

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the materials used, the manufacturing process, the thickness and weight of the geotextile, the orientation and arrangement of the fibers, as well as environmental factors such as exposure to sunlight, moisture, and temperature.

- Q: Can geotextiles be used for reinforcement of pipeline trenches?

- Yes, geotextiles can be used for reinforcement of pipeline trenches. Geotextiles are commonly used in civil engineering projects to enhance the stability and strength of soil. In the case of pipeline trenches, geotextiles can be placed as a separation layer between the soil and the pipeline, preventing soil intrusion and providing additional support to the pipeline structure.

- Q: What are the different factors to consider for geotextile selection in landfill applications?

- There are several factors to consider when selecting geotextiles for landfill applications. These include the type and composition of waste being disposed of, potential chemical interactions, required strength and durability, permeability and filtration requirements, and compliance with regulatory standards. Other factors such as installation and maintenance costs, availability, and environmental sustainability also play a role in geotextile selection for landfill applications.

Send your message to us

Propex Polypropylene Filament Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords