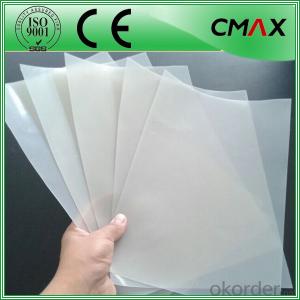

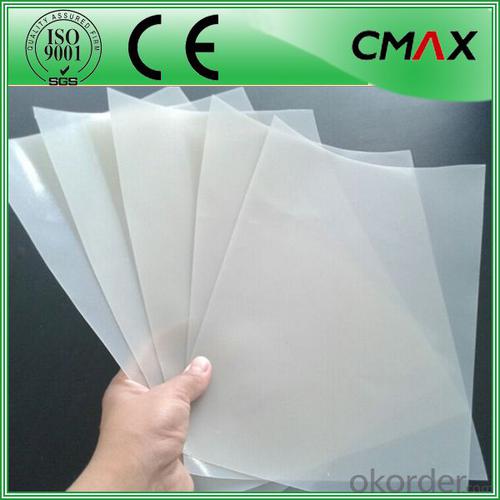

Geotextil N3 Polyethylene Polypropylene Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

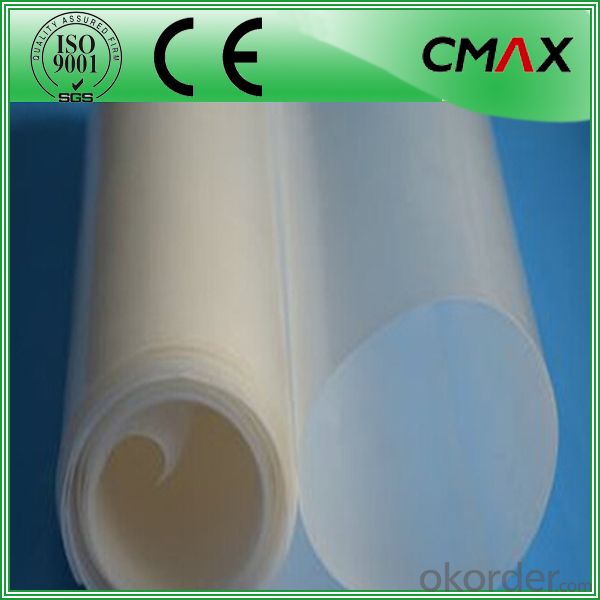

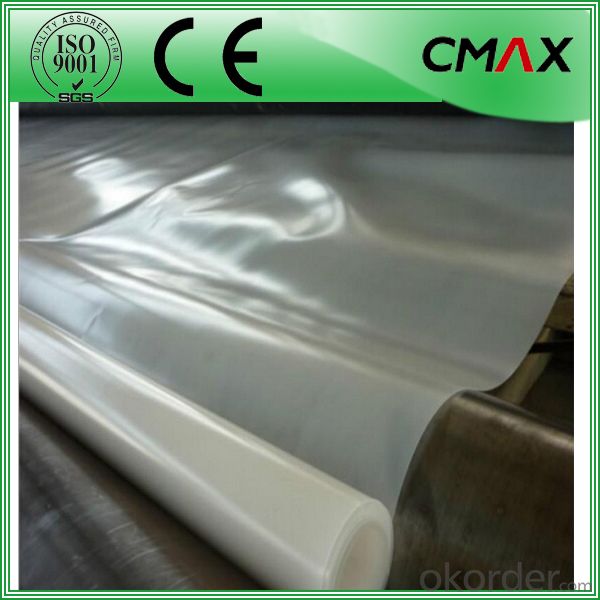

Polyethylene Polypropylene Waterproof Membrane

Geomembrane Features:

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

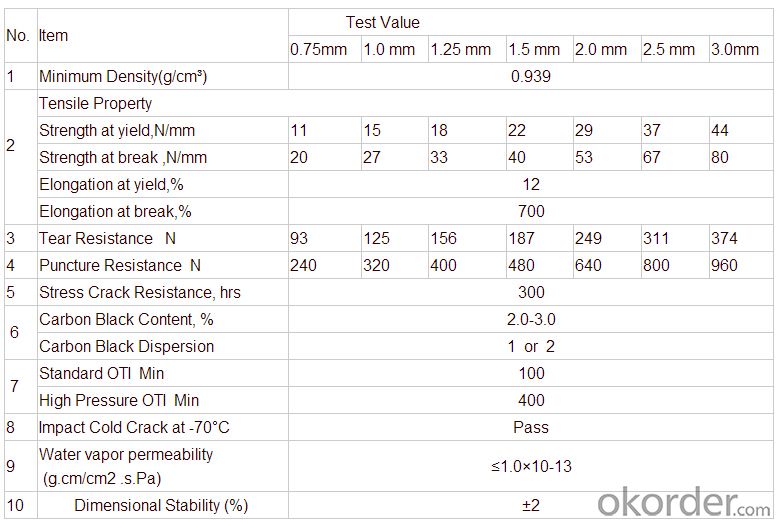

Specifications and Technical datas:

| Thickness | 0.15mm - 4.0mm |

| width | Within 8 m |

| length | 50-100m/roll (at request) |

| Material | HDPE,( LDPE, LLDPE, PVC, EVA ) |

| Color | Black , white , grey |

| Optional surface | Textued(one or two side) or smooth surface |

| Manufacturer | The biggest geomembrane liner manufacturer/factory in China for many years |

Details of our products:

Applications:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Above a geotextile one, that there is any acceptance of norms?

- Geotextile with the relevant national standard, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in railway track stabilization?

- Yes, geotextiles can be used in railway track stabilization. Geotextiles are widely used in civil engineering projects to improve the stability, durability, and performance of the structures. In railway track stabilization, geotextiles can be placed beneath the ballast to prevent the mixing of finer particles with the ballast, reduce track settlement, and enhance the overall stability of the track. Additionally, geotextiles can also help in improving drainage and reducing the maintenance requirements of the railway track.

- Q: What are the advantages of using geotextiles in green roof design?

- Geotextiles offer several advantages in green roof design. Firstly, they provide an effective separation layer between the growing media and the roof membrane, preventing soil erosion and protecting the waterproofing layer. Secondly, geotextiles enhance drainage by allowing excess water to pass through the growing media and into the drainage layer, preventing waterlogging and maintaining a healthy environment for plant growth. Additionally, geotextiles can act as a filtration layer, preventing fine particles from clogging the drainage system and maintaining its functionality. Overall, the use of geotextiles in green roof design improves the longevity and performance of the roof system, while also aiding in stormwater management and plant health.

- Q: Geotextile how much money

- Specifications of different quality prices ranging from geotextiles from November last year to the current price rose too much

- Q: Are geotextiles suitable for use in high-temperature environments?

- No, geotextiles are not suitable for use in high-temperature environments.

- Q: Geotextile 0.2 and 1.0 which is more sunscreen

- Certainly the thicker the more sun, and I professional production geotextile geomembrane, wish smooth

- Q: Geotextile price geotextile how much money a square meter

- Geotextile is a new type of building materials, raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. According to the use of anti-seepage, anti-filter, drainage, isolation, reinforcement, protection, sealing and so on a variety of functions, based on a variety of factors, the price is not the same, we would rather discuss with the price, Hongxiang new materials company Meng Xiangyu that sell products is not just look at profits, if only the simple pursuit of profit level, it is too easy, but if you want to assume the responsibility of the consumer, the quality of the project Responsibility, but need to spend a lot of effort. To this end, we do not count the cost, put a lot of manpower and resources to innovation, to transform, choose the best materials and the best modern equipment, put a lot of manpower, material resources to innovation, to create brand value, Can create the greatest green benefits. High-end quality and green is a commitment, we promise not to short-term interests, betray the future!

- Q: Where to find the right geotextile

- Geotextile types are many, according to the manufacturing process of spinning, woven, woven, according to the material is divided into filaments, short wire and so on, if the most suitable geotextile should be the project requirements are not very strict , Generally like building coverage, road maintenance, etc., like this price is generally around 0.5 angle

- Q: What is the length of the lap when the two-way geogrid is used? What is the geotextile lap length?

- Two-way lap length is 50cm, nailed. Geotextile lap length is 50cm to 1m

- Q: How do geotextiles improve the performance of geopipes?

- Geotextiles improve the performance of geopipes by providing additional reinforcement and filtration capabilities. They act as a barrier to prevent soil particles from entering the pipe, reducing the risk of clogging and maintaining the pipe's hydraulic conductivity. Additionally, geotextiles increase the overall strength of the system, distributing the load more evenly and enhancing the pipe's structural integrity.

Send your message to us

Geotextil N3 Polyethylene Polypropylene Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords