Polyester Plywood Melamine Faced Plywood Board Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Polyester Plywood

Good Quality & Price

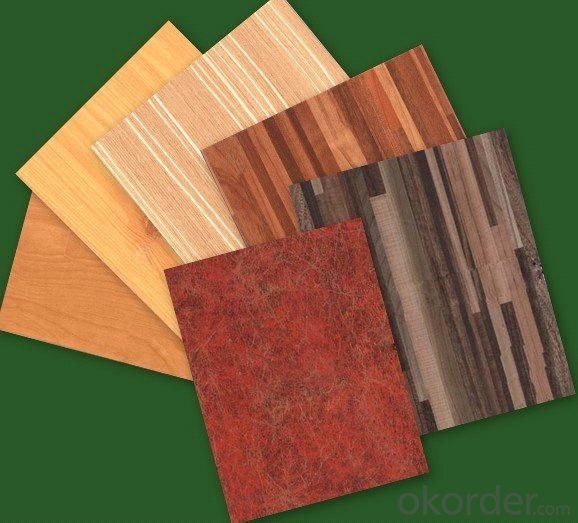

1)Color: solid color, wood grain or marble grain

2)Core: poplar, hardwood, combi

Product Description:

Product Name | COLORFUL POLYESTER PLYWOOD MELAMINE FACED PLYWOOD | |||||

Size | 1220x2440mm, 915x2135mm or as clients requirement | |||||

Thickness | 3~25mm | |||||

Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | |||||

Face/Back | Wood veneer laminated first, then one side or both side melamine laminated | |||||

Surface Treatment | Matt, textured or glossy | |||||

HPL Color | Gray white (There also have other more than 300 kinds color available: solid color (such as black, red, blue, orange, green, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, ect.) & marble grain.) | |||||

HPL Thickness | 0.5~1mm | |||||

Core | Poplar, hardwood, eucalypt, okoume, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Glue | E0, E1, E2, MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | HPL faced plywood is widely used for furniture, cabinet and interior decoration. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’ FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Delivery | loading in 7-10 days or shorter by clients special request.x | |||||

Features: |

1, Transference to concrete is set up very easily, so good for construction work |

2, Waterproof, Wear-resistant, anti-cracking. |

3, After installation of concrete, the surface looks like a mirror. (The cement does not stick.) |

4, It can be used to make camber and it also can be cut into small pieces according the special requirements. |

5. Environmentally friendly |

6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time |

FAQ:

1.Free samples are avaliable

2.Delivery time:20days after getting deposit

3.Payment terms:T/T or L/C at sight

- Q: The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Quality grade for the premium, one, two, three a total of four, the indicator is similar to the MDF, but the intensity is much higher than the MDF

- Q: Plywood is a common material for furniture?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Wood board, plywood, MDF What is the difference

- Blockboard is the core board made of wood board stitching, the two surfaces for the sticky wood veneer solid plate. Veneer, also known as the table, below the board by the board of a board said plate.

- Q: The Preparation of plywood ingredients

- veneer veneer mountain peeling, semi-circular peeling, slicing or sawing the production of flakes of wood.

- Q: Multilayer board, also known as three plywood and plywood

- different layers of different names. According to the thickness of 3-9 cm, can also be called 3-9 PCT board

- Q: What is the density of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: What are the advantages and disadvantages of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: One of the commonly used materials for furniture is a wood-based panel

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each othe

Send your message to us

Polyester Plywood Melamine Faced Plywood Board Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords