Polyester Filament Needle Punched Nonwoven Geotextile Fabric for Drainage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Filament Needle Punched Nonwoven Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function. It separates, stabilizes, and reinforces soils and allows for filtration Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

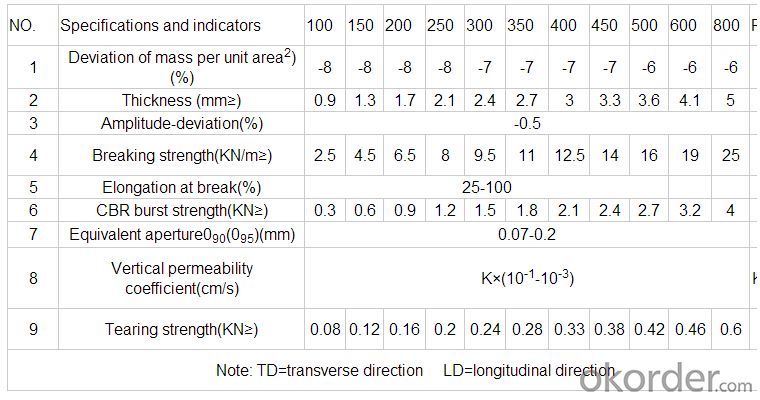

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Water board and water pipes and quick overburden trees

- Set aside the road to pull the car, little by little to fill the soil, I am specializing in the production of geotextile, drainage board, wish smooth

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles contribute to erosion control on slopes by providing stability and reinforcement to the soil. They act as a barrier that prevents soil particles from being washed away by water or wind. The geotextiles also promote vegetation growth and root development, further enhancing their erosion control capabilities.

- Q: Can geotextiles be used for reinforcement of paved surfaces?

- Yes, geotextiles can be used for reinforcement of paved surfaces. Geotextiles are commonly used in civil engineering projects as a way to enhance the performance and longevity of paved surfaces. They provide reinforcement and stabilization by distributing loads and reducing the risk of cracking, rutting, and other forms of pavement distress. Additionally, geotextiles can also serve as a barrier against moisture and prevent the intrusion of fine particles into the pavement layers.

- Q: Reinforced geotextiles and composite soil is not the same

- Reinforced geotextile is from its use up, played a role in reinforcement, called reinforced geotextile. Composite geotextile refers to the process, is woven and non-woven acupuncture geotextile, through the acupuncture together with the geotextile. In other words, the ordinary non-woven acupuncture geotextile and composite geotextile in the use of if it is used to reinforced, can be called reinforced geotextile. Huazhi geotextile material manufacturers

- Q: What are the applications of geotextiles in road construction?

- Geotextiles have several applications in road construction, including separation, filtration, and reinforcement. They are commonly used to separate the subgrade from the base material, preventing mixing and maintaining the integrity of the road structure. Geotextiles also act as a filtration layer, allowing water to drain while preventing the migration of fine particles. Additionally, they provide reinforcement and stabilization to the road, improving its strength and durability. Overall, geotextiles play a crucial role in enhancing the performance and longevity of roads.

- Q: How do geotextiles help with soil erosion control?

- Geotextiles help with soil erosion control by acting as a barrier between the soil and water, preventing the loss of soil particles. They also improve soil stability by increasing its strength and reducing the impact of erosive forces such as wind or water flow.

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together in a regular pattern, creating a strong and durable fabric. Non-woven geotextiles, on the other hand, are manufactured by bonding or felting fibers together, forming a random web-like structure. This results in a fabric that is less strong but offers excellent filtration and drainage properties. In summary, woven geotextiles are stronger and more suitable for applications requiring high tensile strength, while non-woven geotextiles are ideal for filtration and drainage purposes.

- Q: Filament spunbond nonwoven geotextile performance requirements for what is the basic item

- Filament spunbond acupuncture non-woven geotextile is the implementation of the national standard GB / T-2008 standard. GB / T-2008 standard for filament spunbond acupuncture non-woven geotextile performance requirements of the basic items include: product vertical and horizontal nominal fracture strength (KN / m), vertical and horizontal nominal elongation at break (%) (KN), vertical and horizontal tearing strength (KN), mass per unit area deviation (%), width deviation (%), thickness (mm), vertical permeability coefficient (cm / s), equivalent pore size (O90 (95) / mm). Only the above indicators meet the corresponding GB / T-2008 standard requirements, be considered qualified filament spunbonded non-woven geotextile.

- Q: Where to sell waterproof geotextile

- Building materials market should have hope to help you

- Q: Eva waterproof board and ecb waterproof board What is the difference between the two

- Both are waterproof panels, can be used for highway, railway tunnel seepage, but the product material is different, the appearance is not the same. EVA waterproof board there are two conventional, one is a simple EVA waterproof board without composite geotextile, the other is a combination of geotextile with the EVA waterproof board. Two collectively referred to as EVA waterproof board are tunnel waterproof board, is the main material of the tunnel seepage. ECB waterproof board there are two conventional, one is a simple white or black ECB waterproof board, the other is with self-adhesive asphalt waterproofing membrane. Both can be used for tunnel seepage.

Send your message to us

Polyester Filament Needle Punched Nonwoven Geotextile Fabric for Drainage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords