Geogrids Philippines - Polyester Biaxial/Uniaxial Geogrid for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Polyester Geogrid Description

Polyester geogrid is made by polyester, through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips.

The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

2. Geogrid Applications

1)Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

2) Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Geogrid Properties

1) High tensile strength

2) Low elongation

3) Anti-erosion, anti-aging

4) Good affinity with base

5)Light weight, water drainage

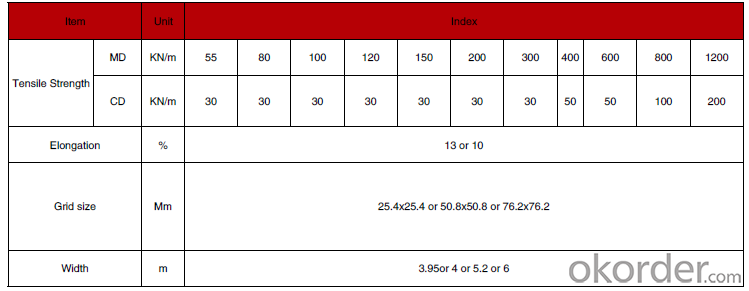

4. Geogrid Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How to connect two-way geogrid

- Transverse 10cm overlap with plastic tape binding on the grid

- Q: Do geogrids have any impact on groundwater?

- Geogrids themselves do not have a direct impact on groundwater. However, they can indirectly influence groundwater flow patterns by improving soil stability and preventing erosion. This, in turn, can potentially affect the recharge of groundwater.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and manufacturer. However, most geogrids range in thickness from 0.5 to 3 millimeters.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%

- Q: Are there any specific requirements for geogrid installation in road construction?

- Yes, there are specific requirements for geogrid installation in road construction. Geogrids should be properly placed and secured at the correct depth and orientation to effectively reinforce the soil and distribute the load. They should be installed on a stable and properly prepared base, with adequate overlap and connection strength. Additionally, compacted fill material should be placed and compacted in layers over the geogrid to ensure proper interlocking and load transfer.

- Q: Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be effectively used in the reinforcement of underground utility corridors. Geogrids provide structural support and stability to the soil surrounding the utility corridors, minimizing the risk of settlement and shifting. They improve the load-bearing capacity of the soil, preventing damage and potential collapse of the underground utility infrastructure. Additionally, geogrids can help distribute loads more evenly and reduce stress concentration, ensuring the long-term durability and performance of the utility corridors.

- Q: GSL50 what is the meaning of Geogrid

- GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q: Can geogrids be used in bridge construction?

- Yes, geogrids can be used in bridge construction. Geogrids are often used as reinforcement materials in bridge foundations, abutments, and retaining walls to improve the stability and load-bearing capacity of the structure. They are effective in preventing soil erosion, reducing settlement, and distributing loads, making them a valuable component in bridge construction projects.

- Q: What are the different types of geogrids available?

- There are several different types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids have strength in one primary direction and are often used for soil reinforcement and slope stabilization. Biaxial geogrids have strength in two directions and are commonly used for pavement stabilization and ground reinforcement. Triaxial geogrids have strength in three directions and are typically used for heavy-duty applications such as retaining walls and embankments.

- Q: Can geogrids be used in landfill liners?

- Yes, geogrids can be used in landfill liners. They are often used as part of a composite liner system to enhance the stability and performance of landfill liners. Geogrids provide reinforcement and improve the tensile strength of the liner, helping to prevent soil erosion and enhance the overall integrity of the landfill liner system.

Send your message to us

Geogrids Philippines - Polyester Biaxial/Uniaxial Geogrid for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords