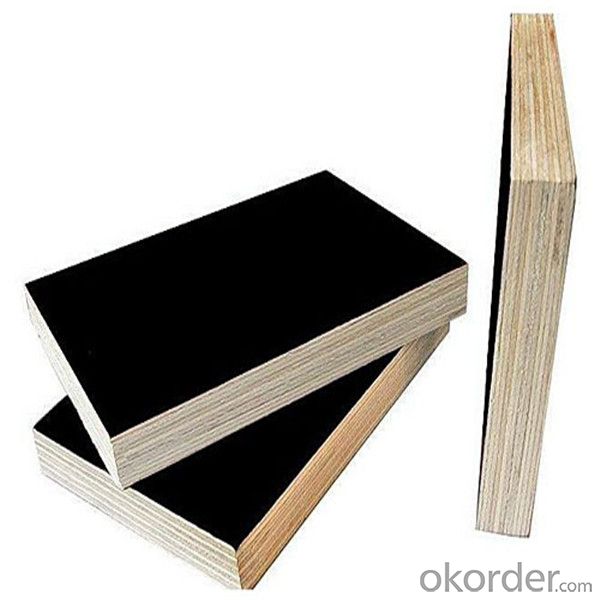

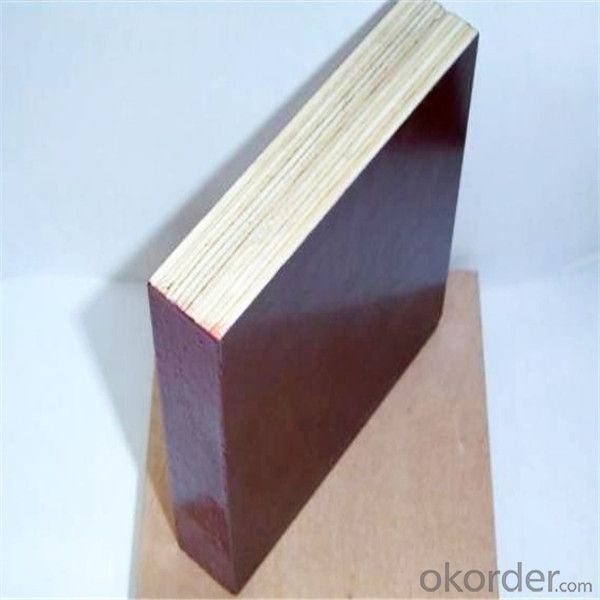

Plywood Hawaii 18mm WBP Glue Brown/Black Film Poplar/Hardwood/Birch Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM |

| Model Number: | GB18580 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | as request |

| Color: | black/brown | Material: | Wood | Wood style: | Panel |

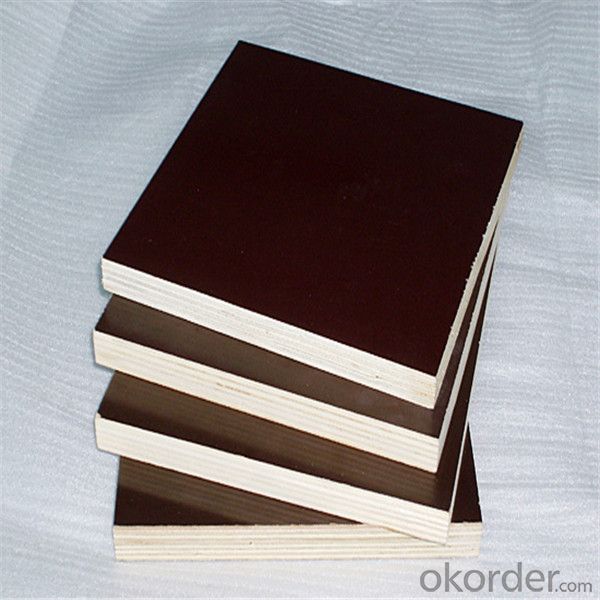

SPECIFICATION

Origin Place | Shandong Province ,China |

Brand Name | CNBM |

Size | 1220*2440mm, 1220*2500mm,1250*2500mm |

Core | Poplar, birch, hardwood, combi |

Glue | MR,WBP,melamine |

Thickness | 3-35mm |

Moisture | 4%-16% |

Certification | ISO9001:2000, CE, |

Production capacity | 10000 Piece/ Day |

Packing | Inner with plastic bag, outer is covered with the carton and plywood, and steel tape for strength |

Payment terms | TT or L/C at sight |

Delivery time | 35 days after receiving the deposit |

Additional | sample available, discount will be given by the large order |

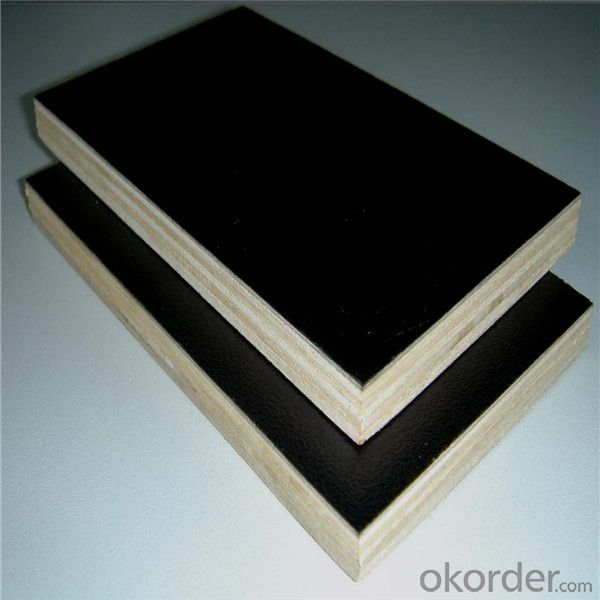

FEATURE

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth

- Q: Plywood in the material defects?

- resin leakage (resin) resin streak trees after the local injury, the resin gathered in a large number of them and through the surrounding wood and the formation of color than the surrounding normal wood deep

- Q: National standards for decorative veneer veneer plywood performance requirements

- The standard on the decorative veneer veneer plywood in the appearance of quality, processing accuracy, physical and mechanical properties of the three aspects of the indicators.

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: What is the use of plywood for construction?

- The outermost front panel is called a panel, the back is called a backplane, and the inner board is called a core plate

- Q: Multilayer board, also known as three plywood and plywood

- . Its main advantages and disadvantages of raw materials, Liu An core 1.2m.4m each board price of 10-20 yuan. And the peach core and poplar will be cheaper.

- Q: Why is the plywood commonly used in the singular layer

- and take a vertical put a then put the plastic in the horizontal put a then In the vertical put a piece into a plywood

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

- Q: Poisoning diagnosis and grading standards

- clinical manifestations of disturbance of consciousness, and exclude other diseases caused by changes in central nervous system function before the diagnosis of acute benzene poisoning; according to the degree of disturbance of consciousness, Severe secondary.

Send your message to us

Plywood Hawaii 18mm WBP Glue Brown/Black Film Poplar/Hardwood/Birch Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords