Plastic Sheets - Light Diffusion Polycarbonate Sheet for LED Light Covering

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

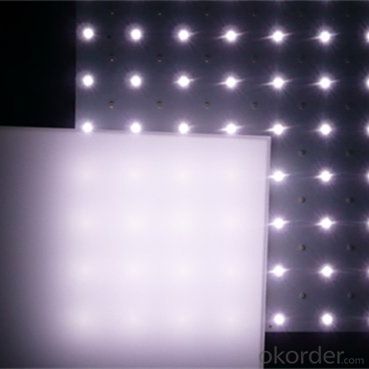

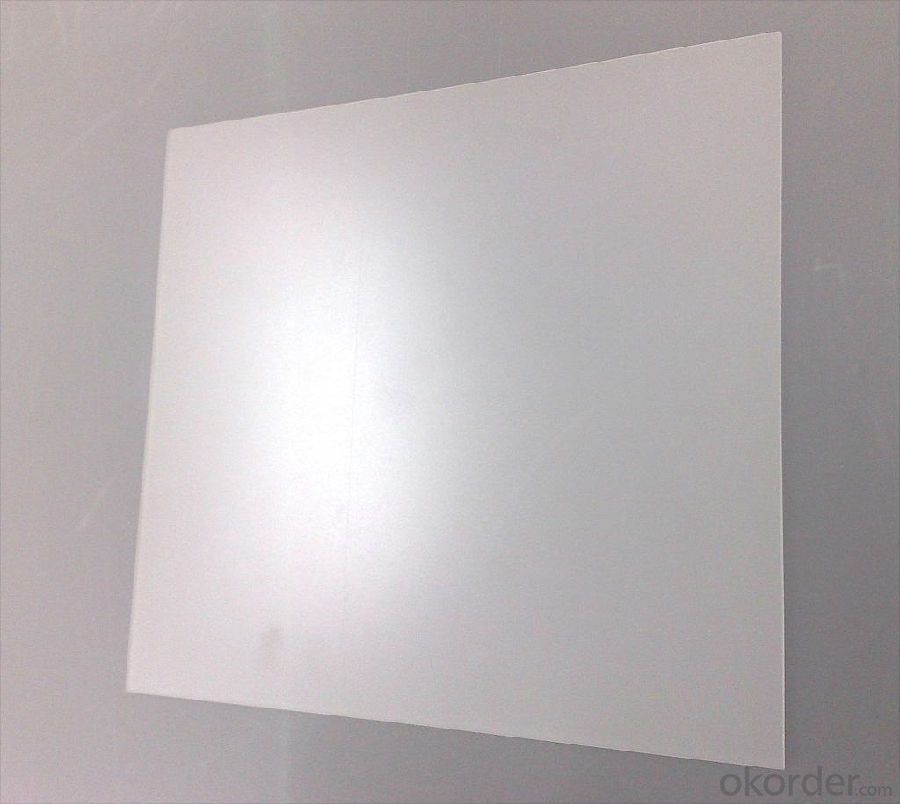

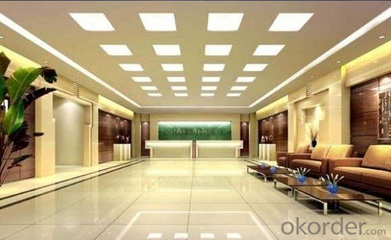

light diffusion polycarbonate sheet for LED light covering

Detailed Product Description

light diffusing polycarbonate sheet

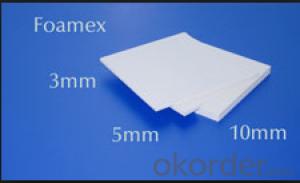

1. 0.5-5mm thick

2.100% vrigin LEXAN material

3. good light diffusing effect

light diffusing polycarbonate sheet

PC advertisement sheet,high impact resistance,good light reflection and transmission ,clear and opal color,competetive price

Specifications:

Maximum width: 2,100mm

Length: any dimension

Specific gravity: 1200kg/cbm

Colors: clear, opal

Technical features:

1) Impact strength: 850J/m ,the impact strength of solid PC sheets is 250 times

that of glass, 20-30 times of PMMA sheet

2) Light transmission: 80%-90% for different thickness of clear color

3) UV resistance:50μm thickness UV layer, the sheet can filter 99% ultraviolet radiation in sunlight

4) Specific gravity: 1.2 g/cm

5) Coefficient of thermal expansion: 0.065 mm/moC

6) Service temperature: -40oC to 120oC

7) Heat conductivity: 2.3-3.9 W/m2 oC

8) Tensile strength: >60N/mm2

9) Flexural strength: 100N/mm2

10) Modulus of elasticity: 2,400mPa

11) Tensile street at break: >65mPa

12) Elongation at break: >100%

13) Specific heat: 1.16J/kgk

14) Heat deflection temperature: 140oC

15) Soundproof index:4mm thickness--27dB,5mm--28dB,6mm--29dB

- Q: The plastic board is brittle at low temperature

- Plastics are polymer materials at room temperature showed a hard and tough, in higher temperature conditions will exhibit toughness even elasticity, once the temperature is reduced to below the glass transition temperature or brittle point, will show the fragility of.

- Q: PE plastic sheet surface how to film?

- First of all, you want to tear off, that is to say, the film should melt into the board, so it must be the film in the mold out of a plate where the beginning of the cover. Add a pneumatic shaft in front of the first roller to cover the film roll. Then, every time you change the film volume, the front ten meters or less.

- Q: What is the thickness range available for plastic sheets?

- The thickness range available for plastic sheets can vary greatly depending on the type of plastic. However, commonly available plastic sheets can range from as thin as 0.01mm to as thick as 25mm or more.

- Q: what is the overlayer plastic sheet used on standard dvd and game case called?

- it particularly is thoroughly pointless, i think of human beings could basically have the skill to purchase movies of On call for or Verizon and function the skill to maintain them continually on like a stored folder, and then with comparable track on Itunes and automobiles could come put in with iPod holders so which you will play that quite of CD's, haha I easily have extraordinary philosophy.

- Q: I mean the sheet that is used to make control panels its normally black and when etched it shows white, do any companies offer a custom service who sells it whats the term for this

- a b s plastic?

- Q: How do I remove the double adhesive on the plastic board?

- When the double adhesive is torn, use the electric hair dryer to heat it, and no trace will be left. If it is not heated, leave a mark after tearing off.

- Q: Where can i buy big sheets of Coroplast?

- I okorder / ... HTH, Diane B.

- Q: Where do u buy sheets of plastic mirror used in magic that are about 5 feet by a little over 2 feet?

- Builder's Square (now out of business) used to carry them. I bought some and attached them to a three-panel screen to use when I practiced tap dancing. Home Depot and Lowe's carried them at one time in their plexiglas sheets department, near the hardware, and in their ceiling panels department, near the lighting. If you have a Sutherlands Lumber near you, you might check with them.

- Q: The plastic board is good to choose plastic chopping board

- Disadvantages: 1. plastic boards are not resistant to high temperature, easy deformation. 2. textured plastic boards, easy to cut out the plastic powder, the powder into the human body harm. Plastic board for its beautiful delicate appearance can attract a lot of women in the family. Buy plastic chopping board can not only see the appearance of exquisite beauty, can not just look at the cheaper price and then feel the benefits.

- Q: How are plastic sheets different from other materials like glass or metal?

- Plastic sheets are different from other materials like glass or metal primarily due to their composition and properties. Unlike glass, plastics are synthetic materials derived from polymers, making them more flexible, lightweight, and less brittle. Plastic sheets are also transparent or translucent, similar to glass, but are less prone to shattering. In contrast to metals, plastic sheets are non-conductive, have lower density, and offer better insulation properties. Additionally, plastics are generally more cost-effective, easier to mold, and can be manufactured in a wide range of colors and textures, making them highly versatile in various applications.

Send your message to us

Plastic Sheets - Light Diffusion Polycarbonate Sheet for LED Light Covering

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords