Plastic Sheets - Imitation UV Coating Marble PVC Sheet / PVC Board / PVC Foam Board for Ceiling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

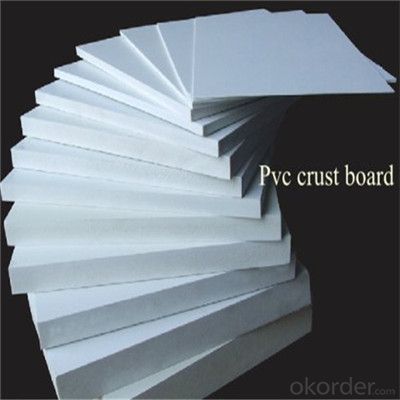

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

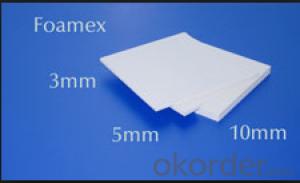

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request.

Thickness:1-33mm

Density:0.43mm-0.9mm

3.Application Of PVC

1,PVC foam board has characters like being soundproof,sound absorption,heat insulation, heat preservation

2,Our board has characters fire resistance, it can be self extinguishing ,can be used safely

3,It’s enviromental and nontoxic, does not include formaldehyde etc. harmful gas ,it can be called “Green products”

4,Different series products have moistureproof, zymosis proofing, no sob, shock proof effect is great

5,Different series product can be produced by weather resistance formulation , the color can stay long time ,and not easy to be aging

6,Our product is light and easy to storge and convinent to construct

7,Our product can be constructed by normal wood processing tools

8,It can be drilled saw, nailed, dig, glue etc. processing

9,It can be used for thermal forming, hot bending and foldig processing( besides fire-proof sheet)

10,It can be welded according to normal welding procesdures, also can be adhered with other PVC material

11,It is widely used in bathroom,kitchen,warehouse ect

Also can be used as Advertisement board,canbe printed on it.

4. FAQ

Q1. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q2. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q3. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

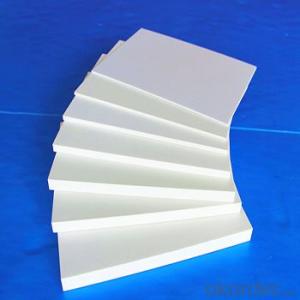

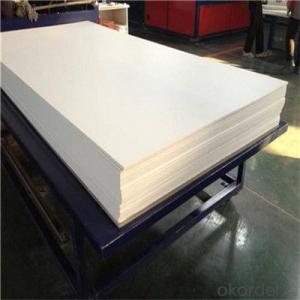

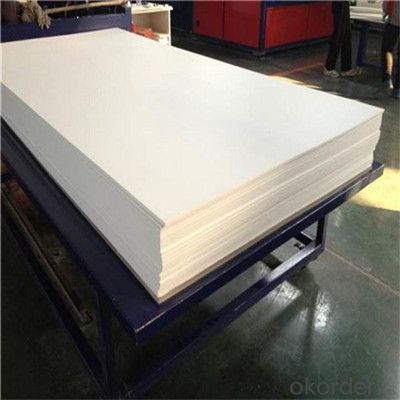

5.Product photo

- Q: I have a large sheet of plastic, or I think its plastic. Its about 1/8 inch thick, knubby on one side, smooth on the other and slightly pliable. I'd like to cut equal size panels to fit into my window shutters. I tried using a glass cutter and T square but that didn't work. Any suggestions?

- Use a Stanley knife. With a straight edge, score the smooth side several times. Now lay the sheet on a table with the score line right at the edge. Have a second person press down with a board on top of table to keep sheet from moving. (Place board right at edge) Person one now presses down on sheet to snap. Do it in one quick move.

- Q: Are plastic sheets resistant to humidity?

- Yes, plastic sheets are generally resistant to humidity.

- Q: Are plastic sheets resistant to discoloration from humidity?

- No, plastic sheets are not completely resistant to discoloration from humidity. High levels of humidity can cause certain types of plastic sheets to absorb moisture, leading to discoloration and even the growth of mold or mildew. However, some plastic sheets are specifically designed to be more resistant to humidity and discoloration, so it depends on the type and quality of the plastic sheet being used.

- Q: it touched a plastic bag right when it came out of the oven and now it's stuck on and hard as a rock. how do i get it off?

- I did that once, I got it off with a spatula....a spatula, and oil..

- Q: How can the stains on the plastic steam plate be removed?

- Secret weapon: quick cleaning plastic chopping board 84 disinfectant.Step 1 cleaning with water, diluted 84 disinfectant, usually a bowl of water poured into a small bottle can, according to the number of cleaning items can also adapt to put a little more.

- Q: why do people put plastic sheeting down before pouring concrete? I think i know but want to here from experts.?

- That prevents the salt and moisture in the earth from penetrating the concrete, intermingling with the lime in concrete. Some concrete contains ground Oyster Shell, compounding the problem. This occurs through hydrostatic pressure. When that happens, Alkali forms and deposits on the surface of the slab. When hard surface flooring of any kind is glued to the slab, Alkali destroys the adhesives. Sometimes, before that happens Alkali will penetrate through the concrete creating deposits between grout lines of tiles of flooring. It appears as a white powder. There are times when the plastic may be ruptured and sometimes it does not prevent some formation of Alkali. Alkali travels, damn near like an animal and creates fits for flooring. Much research and many products have been produced to combat Alkali. None are 100% remedies. Sometimes Plywood sub flooring is the only answer.

- Q: The sheets are labeled top and Bottom. Does that mean the top would go nearest the keys, or as I'm looking at it from the back?

- I'm assuming it's the crumb barrier... the clear plastic between the keys and actual mechanics of the keyboard. It should only fit one way. If top doesn't fit at the top, put top at the bottom. If it fits both ways then it doesn't really matter.

- Q: Are plastic sheets resistant to impact?

- Yes, plastic sheets are generally resistant to impact due to their inherent flexibility and durability.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: Can plastic sheets be used for protective shields in sports?

- Yes, plastic sheets can be used for protective shields in sports. They are commonly used in various sports such as hockey, football, and baseball to provide a barrier between players and potential injuries. Plastic sheets offer impact resistance, visibility, and flexibility, making them suitable for protective shields in sports.

Send your message to us

Plastic Sheets - Imitation UV Coating Marble PVC Sheet / PVC Board / PVC Foam Board for Ceiling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords