China Geotextile Bag Plastic Grass Grid for Land Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

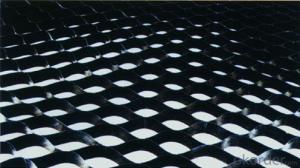

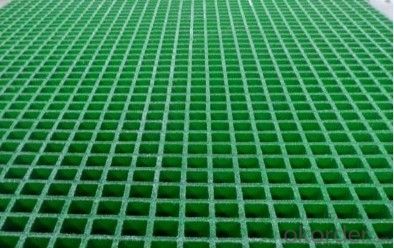

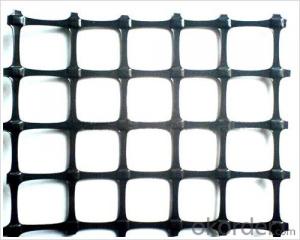

1,Description of Plastic Grass Grid

Nature Planting grass grid using modified high molecular HDPE as raw materials , Green and Environmental Protection , Completely recyclable , it can perfect realize to combine the lawn and parking lot,it can bear pressure , abrasion resistance, impact resistance, antiaging, corrosion resistance , improve the quality , and save the investment; unique flat plug type overlap joint , improve work efficiency and quick install , can adjust expansion joint .

Material : Modified high molecular HDPE , Fiberglass , Nanometer oxide , Coloring Material ( standard ratio) .

Color : green color or other any specified color

Bearing capacity : The hightest 200T/m2

2,Specialities of Plastic Grass Grid

1) High strength , long life service .

2)Nature Planting grass grid use special material with patent technology , maximum stress tolerance can meet 200T/m2 , greater than 32T/m2 for standard requirement fire fighting high surface .

3) Stable performance , anti-UV , resistance to acid and alkali corrosion , anti-wear and pressure , anti-temperature -40°C-90°C. (Reference : concrete planting grass brick will be easy to craze and damage when temperature variation ) .

4) Good drainage .

5) Gravel bearing layer provides good drainage function , so that easy to drain excessive rainfall .

6) Lap joint . flat plug type overlap joint , very convenient , arbitrarily adjust expansion joint width , to fit temperature change

3, Application of Plastic Grass Grid

Parking lot , Fire fighting access , Fire fighting high surface , Golf lane , Conference and exhibition center , Modern workshop , Upscale community , Roof garden and so on .

4,Construction suggestions:

Foundation soil should be compaction as different layers , Compactness should be reach more than 85% .

Gravel bearing should be paved 350 thickness (Fire lane should be 600 thickness) , spread out to flat and grind to compaction .

Gravel or coarse sand should be paved 20thickness .as the flat layer .

Pave and install grass grid can be cut to suitable size by saw , and you should leave a few millimeters slit between grid and grid .

Sowing planting soil on the grid surface from the top about 1.0cm

Lay down in grass or sowing grass seed . While lay down in grass , .turfing has to be compacted , watering and maintaining , you can park car when grass grow .Protecting lawn .

Gravel bearing layer can supply some store water function , this is beneficial for lawn grow , grass roots can grow to gravel layer .(Reference: concrete planting grass brick only has small space , and when under summer sunshine , temperature will reach more than 50 °C ) .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing reinforcement and stabilization. They help to prevent erosion, soil movement, and surface runoff by acting as a barrier between the soil layers. Additionally, geotextiles increase the overall strength of the slope, reducing the risk of landslides or slope failures.

- Q: How do geotextiles help in stabilizing railroad tracks?

- Geotextiles help in stabilizing railroad tracks by providing reinforcement and separation between the track components and the underlying soil. They prevent the mixing of soil particles with the track ballast, which can lead to track settlement and degradation. Geotextiles also distribute the load of passing trains more evenly, reducing the risk of track deformation and improving overall stability.

- Q: How do geotextiles contribute to groundwater protection?

- Geotextiles contribute to groundwater protection by acting as a barrier between the soil and any potential contaminants. They prevent the infiltration of pollutants into the groundwater by providing a filtration layer that allows water to pass through while trapping harmful substances. Additionally, geotextiles help in stabilizing the soil, reducing erosion and sedimentation that can impact the quality of groundwater.

- Q: What are the key considerations for geotextile installation in high temperature environments?

- Some key considerations for geotextile installation in high temperature environments include selecting a geotextile material that can withstand high temperatures without degrading or losing its property, ensuring proper storage of the geotextile rolls to prevent heat damage before installation, using appropriate installation techniques to minimize the exposure of the geotextile to direct sunlight or extreme heat, and conducting regular inspections and maintenance to monitor the performance of the geotextile in the high temperature environment.

- Q: What are the specifications for geotextiles used in erosion control tubes?

- The specifications for geotextiles used in erosion control tubes typically include factors such as high tensile strength, UV resistance, permeability, and durability. These geotextiles are typically made from synthetic materials like polypropylene or polyester and are designed to effectively prevent soil erosion while allowing water to pass through. They should also be able to withstand various environmental conditions and have a specific pore size to retain soil particles and prevent clogging.

- Q: 200g / m2 geotextile how to enter the inspection test

- In accordance with national standards for testing ah

- Q: What are the factors to consider when selecting a geotextile for a specific application?

- When selecting a geotextile for a specific application, there are several factors to consider. Firstly, the intended function of the geotextile needs to be evaluated. This includes determining whether it will be used for separation, filtration, reinforcement, or drainage purposes. Secondly, the site conditions and environmental factors such as soil type, climate, and potential chemical exposure must be taken into account. The required strength, durability, and longevity of the geotextile should also be considered. Additionally, the cost-effectiveness and availability of the specific geotextile should be assessed. Finally, the installation and maintenance requirements of the geotextile need to be evaluated to ensure proper implementation and long-term performance.

- Q: How do geotextiles help with erosion control?

- Geotextiles help with erosion control by providing a protective barrier against soil erosion. They are designed to be permeable, allowing water to pass through while preventing the loss of soil particles. Geotextiles also stabilize soil by increasing its strength and preventing it from being carried away by wind or water. Additionally, these materials promote vegetation growth by retaining moisture and nutrients, further enhancing erosion control efforts.

- Q: What are the limitations of using geotextiles in high-water flow conditions?

- One limitation of using geotextiles in high-water flow conditions is their potential to clog or become blocked with sediment or other debris. This can reduce their effectiveness in filtering water or preventing erosion. Additionally, geotextiles may not be able to withstand the extreme forces exerted by fast-moving water, leading to their failure or displacement. Therefore, it is crucial to carefully consider the flow conditions and choose appropriate geotextiles with sufficient strength and porosity for the specific application.

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- I professional production geotextile geomembrane and other materials, wish smooth

Send your message to us

China Geotextile Bag Plastic Grass Grid for Land Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords