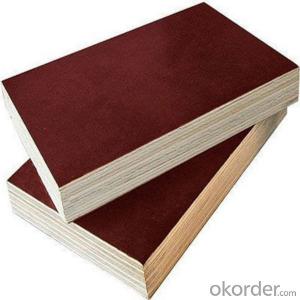

Phillips Plywood Bintangor Face and Back Poplar Core BBCC Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Bintangor plywood

Face/Back: Bintangor

Core: Poplar,Hardwood,Pine,Birch,Eucalyptus,Combi etc

Size: 1220×2440mm,1250×2500mm,1220×2150mm,1830×3660mm etc

Thickness: 2.7-30MM

Thickness Tolerance: +-0.1mm~0.3mm <6mm

+-0.3mm~0.5mm >6mm

Glue:WBP/MR/MELAMINE/E0/E1/E2

Grade:BB/BB BB/CC CC/CC etc

Moisture: 8-14%

MOQ: 40HQ

Packing Details: 20GP 8pallets/21M3

40GP 16pallets/42M3

40HC 18pallets/53M3

Payment Terms: 30%T/T in advance,70%L/C

Delivery Time: 15 to 20 days after receiving 30%T/T down payments

Commercial Plywood Quality Standard (OKOUME and BINTANGOR F/B, POPLAR CORE) | ||||||||||||||

Defects | Unit | Face | Back | |||||||||||

BB/BB Grade | BB/CC Grade | BB/BB Grade | BB/CC Grade | |||||||||||

Pin Knots | Allowed | |||||||||||||

Life knots | Maximum diameter (mm) | 19 | 25 | 19 | 30 | |||||||||

Maximum number per m2 | 2 | 3 | 2 | 5 | ||||||||||

Half-Life Knots; Dead Knots(not fall off) ; Inbarks

| Altogether

| Maximum number per m2 | Not allowed

| 2 | Not allowed

| 4 | ||||||||

Half Life Knots

| Maximum diameter (mm) | Not allowed

| 10 | Not allowed

| No limitation

| |||||||||

Dead Knots(not fall off) | Maximum diameter (mm) | Not allowed

| 4 | Not allowed

| 20 | |||||||||

Inbarks

| Maximum diameter (mm) | Not allowed

| 15 | Not allowed

| 20 | |||||||||

Splits | Closed | Not allowed

| Not allowed

| Not allowed

| ≤2x300mm permitted; must repair by similar color putty(2x300mm | |||||||||

Insect Holes | Maximum diameter (mm) | Not allowed

| 2 | Not allowed

| 4 | |||||||||

Maximum number per m2 | 4 | 4, if<2mm, there is no limitation on the number | ||||||||||||

Face Contamination | Maximum area (% of total surface) | Not allowed

| Not allowed

| Not allowed

| 0.5 | |||||||||

Discoloration | Maximum area (% of total surface) | Not allowed | 5 | Not allowed | 40 | |||||||||

Rot | Maximum area (% of total surface) | Not allowed

| ||||||||||||

Veneer shortage and damage of four corners | Not allowed

| Not allowed

| Not allowed

| Not allowed

| ||||||||||

Delamination | Not allowed | |||||||||||||

Blisters | Not allowed | |||||||||||||

Sandthrough | Not allowed | |||||||||||||

Torn Grain

| Maximum area (% of total surface) | Not allowed

| Not allowed

| Not allowed

| 5 | |||||||||

Excess Sanding | Max mm2 per m2 | Not allowed

| ||||||||||||

Mending | Maximum size per surface

| Not allowed

| Not allowed

| Not allowed

| ≤50x100mm (boat mending) ≤50x100mm | |||||||||

Maximum number per surface | 3 | |||||||||||||

Core Grade

| First grade and second grade mixed. For 3mm,must be first grade | |||||||||||||

Core voids | ≤3mm, but it can not affect the intensity | |||||||||||||

Overlap and Splits at the Other Cores | Maximum length (mm) | ≤10mm

| ||||||||||||

Overlap and Splits at the Core which Adjacent to the Top and Bottom Veneers

| Maximum width (mm)( | Not allowed

| 1.5 | Not allowed

| 3 | |||||||||

Maximum number

| 2 | 3 | ||||||||||||

Core mending | Must mend by wood-wool | |||||||||||||

Panel edge | Must smoothly | |||||||||||||

Hollowness/Imprints/Bumps | Maximum surface (mm2) | Not allowed

| 20 | Not allowed

| 40 | |||||||||

Maximum number per m2 | 1 | 1 | ||||||||||||

Maximum depth (mm) | 0.4

| Allowed if there is no breach

| ||||||||||||

Tolerance(公差)

| 1. Length is +/-1mm 2. Width is +/-0.5mm 3. Thickness <9mm +/-0.3mm ≥9mm +/-0.5mm 4. MC: <9mm 8-12%;≥9mm 8-14% 5. Veneer thickness tolerance: Not below 0.3mm after sanding | |||||||||||||

- Q: Why plywood is cheaper than solid wood

- Without changing the physical properties of wood under the premise of drying, liposuction, paint and other processes can be called solid wood. Plywood (English: Plywood,

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: How do I determine if plywood contains formaldehyde?

- because it is often hidden behind the wood epidermis and must be carefully viewed, usually in seams and drills Of the place can be seen clues

- Q: Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: What types of plywood can be divided into?

- It can withstand cold water or short-term hot water immersion, but not resistant to boiling.

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Hard fiber board is also a density board

- the same texture direction. Adjacent two-layer veneer grain direction should be the same. The plywood should be the same tree.

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

Send your message to us

Phillips Plywood Bintangor Face and Back Poplar Core BBCC Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords