Specifications

electronic test PCB

a. PCB OEM&ODM

b. PCB Clone/Copy,Design

d. Turnkey service

e. UL,SGS,RoSH,TS certificate

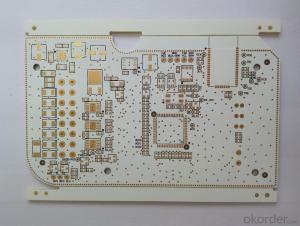

PCB Manufacturer

OurPCB Technical capabilities

NO | ITEM | Technical capabilities |

1 | Layers | 2-20 layers |

2 | Max. Board size | 2000×610mm |

3 | Min. board Thickness | 2-layer 0.15mm |

4-layer 0.38mm |

6-layer 0.55mm |

8-layer 0.80mm |

10-layer 1.0mm |

4 | Min. line Width/Space | 0.075mm(3mil) |

5 | Max. Copper thickness | 6OZ |

6 | Min. S/M Pitch | 0.075mm(3mil) |

7 | Min. hole size | 0.1mm(4mil) |

8 | Hole dia. Tolerance (PTH) | ±0.05mm(2mil) |

9 | Hole dia. Tolerance (NPTH) | +0/-0.05mm(2mil) |

10 | Hole position deviation | ±0.05mm(2mil) |

11 | Outline tolerance | ±0.10mm(4mil) |

12 | Twist & Bent | 0.75% |

13 | Insulation Resistance | >1012 Ω Normal |

14 | Electric strength | >1.3kv/mm |

15 | S/M abrasion | >6H |

16 | Thermal stress | 288°C 20Sec |

17 | Test Voltage | 50-300V |

18 | Min. blind/buried via | 0.15mm (6mil) |

19 | Surface Finished | HAL, ENIG, ImAg, Imsn OSP, Plating AG, Plating gold |

20 | Materials | FR4,H-TG,Teflon,Rogers,Ceramics,Aluminium, Copper base

|