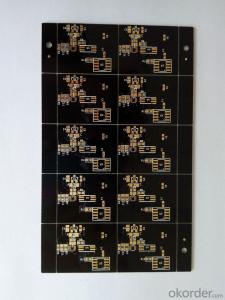

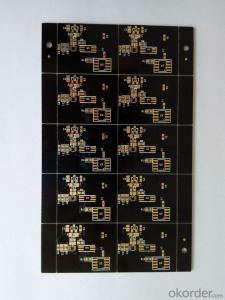

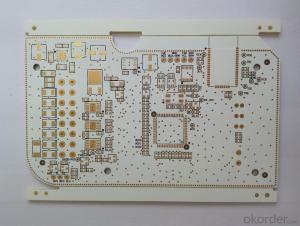

High quality 2 layer flex pcb, UL approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1. UL,ISO9001,ISO14001, TS16949 certificate

2. Short lead time.

3. PCB ROHS compliant.

4. Turkey service

Free Technology Support

PCB Assembly

Turnkey service(PCB manufacture, components procurement and assembly)

Minimum lead time for assembly is only 5 days

Prototype building, No Minimum quantity Required

Reliable Parts

Surface mount, through hole, BGA, QFP, QFN …

ROHS compliant and lead-free process

PCB Capability

Material: FR4, CEM-3, Halogen Free, Rogers, High TG etc.

Layer counts: 1-18 layers

Finished Copper Thickness: 0.5-4 OZ

Finished Board Thickness: 0.2-5.0mm

Min. Line/Track Width: 4mil

Min. Line/Track Space: 4mil

Min. Contour Tolerance: +/-0.1mm

Min. Finished Diameter of PTH Hole: 0.2mm

Max. Board Thickness/Hole Ratio: 12:1

Min. Solder Mask Bridge: 4mil (Min. SMT Pad Space 8mil)

Min. Legend (Silk screen) Track Width: 5mil

Min. Legend (Silk screen) Height: 30mil

Min. drilling slot size: 0.6mm

Solder mask color: green, black, blue, white, yellow, purple, and matt, etc.

Legend/Silk screen Color: white, yellow, black, etc.

Surface Treatment: HAL, Lead Free HAL, Immersion gold, OSP, Immersion tin, Immersion silver, etc.

Other Technology: Gold finger, peelable mask, Non-across blind/buried vias, characteristic impedance control, Rigid-flex board etc.

Reliability Test: flying probe test/fixture test, impedance test, solderability test, thermal shock test, hole resistance test, and micro metallographic section analysis, etc.

Bow and twist: ≤1%

Flammability: 94V-0

4. Professional engineering staff to provide technical support.

5.OEM and ODM service are welcome.

Packaging Detail: Vacuum packaging

Delivery Time: 10-15 days

- Q: Circuit board of the green skin and silver contacts were burned iron, but also use it?

- Circuit board can be called printed circuit board or printed circuit board, the English name for (Printed Circuit Board) PCB, (Flexible Printed Circuit board) FPC circuit board [1] (FPC circuit board, also known as flexible circuit board flexible circuit board is poly Imide or polyester film made of a substrate with a high degree of reliability,

- Q: What is the difference between PCB and FBC?

- FBC is fed-batch fermentation (fed-batchculture, referred to as FBC), also known as semi-continuous culture or semi-continuous fermentation, refers to the batch fermentation process, intermittent or continuous to add one or more

- Q: What size measurements are required for printed circuit boards?

- Circuit board name: circuit boards, PCB board, aluminum plate, high frequency board, thick copper plate, impedance board, PCB, ultra-thin circuit boards, ultra-thin circuit boards, printing (copper etching technology) circuit boards. The circuit board makes the circuit miniaturized and intuitive, which plays an important role in the mass production and optimization of the fixed circuit.

- Q: What are the FPC flexible printed circuit board materials?

- Due to the low glass transition temperature of the acrylic adhesive sheet, the large amount of contamination caused by the drilling process is not easy to remove, the quality of the metal hole, and other bonding materials are unsatisfactory. Therefore, the multilayer flexible circuit As the polyimide material, the CTE (thermal expansion coefficient) is consistent with the polyimide substrate, which overcomes the problem of dimensional instability in the multilayer flexible circuit, and the other properties are satisfactory The

- Q: What is the difference between PCB and FPC?

- FPC generally operates in the need to repeat the deflection and some small parts of the link, such as clamshell phone clamshell part, the printer links the print head parts, various modules (such as the display module on the motherboard connection)

- Q: Flexible circuit version why not eliminate pcb hard printed circuit board

- The benefit of the flexographic version is that it can be fitted to where it needs to be bent, but for flexo, its performance is affected by the number of times of bending and the environment in which it is used, and in many cases it can not be used repeatedly and can be found

- Q: Protel99 painting FPC, in the middle of the FPC hollow only exposed bare copper (FPC welded to the PCB board) how to draw it can be achieved?

- FPC, flexible circuit board is a polyimide or polyester film made of a highly reliable, excellent flexible printed circuit board. With high wiring density, light weight, thin thickness, good bending characteristics.

- Q: What is FPC in Electrical Diagram

- Rigid PVC pipe: from the polyvinyl chloride resin by adding stabilizers, lubricants and other additives by kneading, rolling, plasticizing, pelletizing, extrusion molding processing, and acid, heating simmer bending, cooling Stereotypes are available. Mainly used for wire, cable protection casing and so on. Pipe length is generally 4m / root, the color is generally gray. Pipe connection is generally heated socket-type connection and plastic hot air welding, bending must be heated

- Q: FPC tube and PVC pipe is different

- The difference between the two is different plastic pipe, FPC is a semi-rigid plastic pipe, PVC is generally rigid plastic pipe.

- Q: What are the processes on the circuit board?

- Therefore, the soft and hard bonding board, that is, flexible circuit boards and rigid circuit boards, after pressing and other processes, according to the relevant process requirements together to form a FPC characteristics and PCB characteristics of the circuit board.

Send your message to us

High quality 2 layer flex pcb, UL approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches