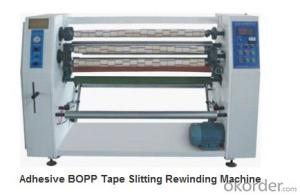

OPP Perforation Film Slitting Rewinding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

The OPP perforation film slitting rewinding machine is used to slit and rewind various large rolling materials such as paper with weight between 20g/㎡and 300g/㎡, cellophane or bill paper, double-face or single face adhesive tape, weave material, nonwoven fabric, OPP, PET, FILM, AL, PVC, copper foil and others. The slitting rewinding machine also comes with a perforator using hot needles to punch holes.

The OPP perforation film slitting rewinding machine uses automatic taper tension and central surface reeling. It has frequency converter timing to keep speedup and stable operation, also with automatic metering and alarm. The OPP perforation film slitting rewinding machine adopts A and B pneumatic shaft structure for rewinding, easy for loading and unloading.

The OPP perforation film slitting rewinding machine has photoelectric automatic error adjustment system for unwinding, atypical materials will be easy to slit. The OPP perforation film slitting rewinding machine is set with automatic waste film blowing device by circle blade and automatic input material.

2.Technical Data of OPP Perforation Film Slitting Rewinding Machine

| Model | WZFQ-1100 CP | WZFQ-1300 CP | WZFQ-1600 CP |

| Max unwinding width | 1100 mm | 1300 mm | 1600 mm |

| Max unwinding diameter | ¢ 1400 mm (700 mm option) | ¢ 1400 mm | ¢ 1400 mm |

| Min slitting width | 30 mm | 30 mm | 30 mm |

| Max rewinding diameter | ¢ 5 00 mm | ¢ 5 00 mm | ¢ 5 00 mm |

| Speed | 10-160 m/min | 10-160 m/min | 10-160 m/min |

| Precision | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm |

| Total power | 12 Kw | 12.8 Kw | 16 Kw |

| Suitable power supply | 380 v/50 Hz | 380 v/50 Hz | 380 v/50 Hz |

| Weight (approx) | 3000 Kg | 3200 Kg | 3800 Kg |

| Overall dimension L × W × H (mm) | 3000 × 2200 × 1600 | 3000 × 2400 × 1600 | 3000 × 2700 × 1600 |

3. Advantages

We've been specialized in packaging machine for more than ten years, we know this product very well, and we have good finacial support from government.

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 50 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q: What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

OPP Perforation Film Slitting Rewinding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords