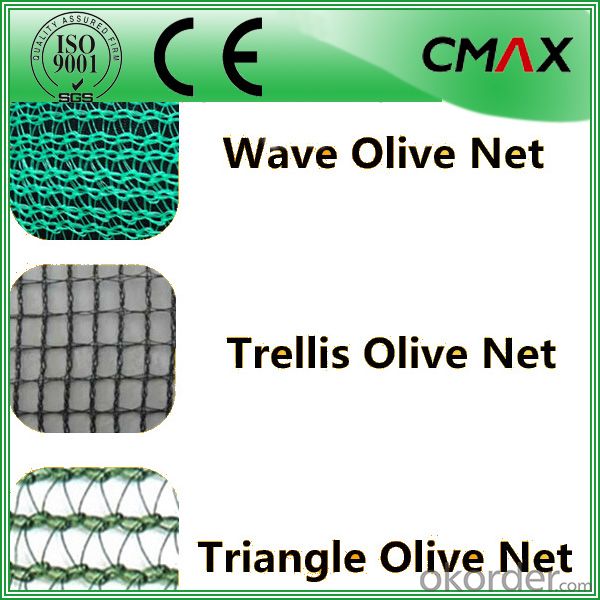

Olive Collection Olives Nets for Farms Net

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

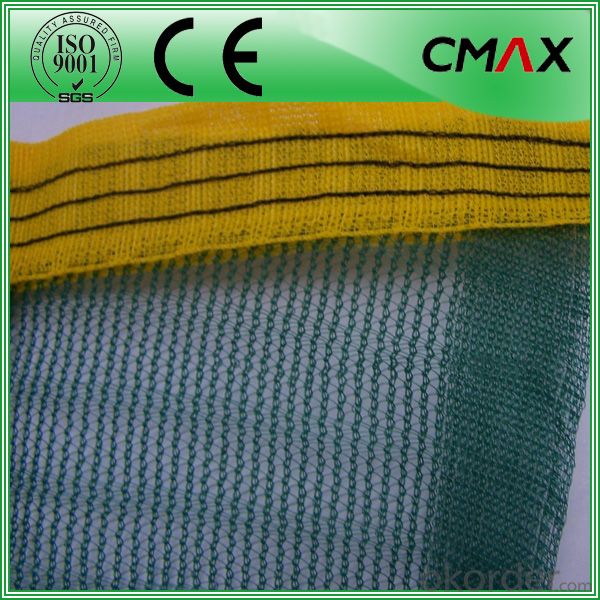

Olive Collection Olives Nets for Farms Net

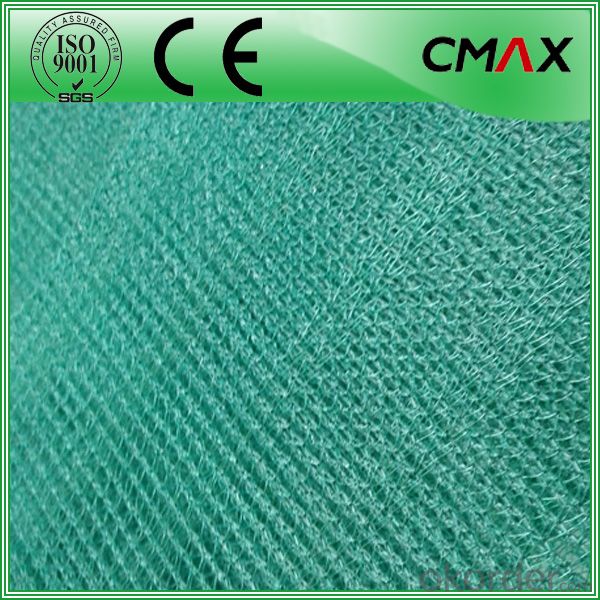

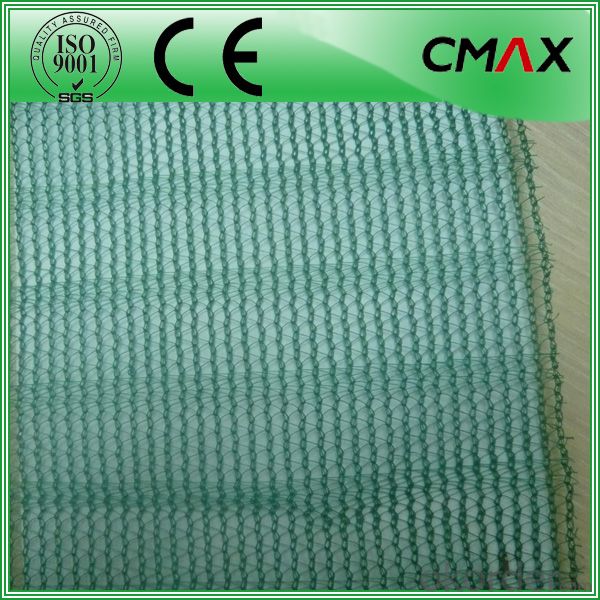

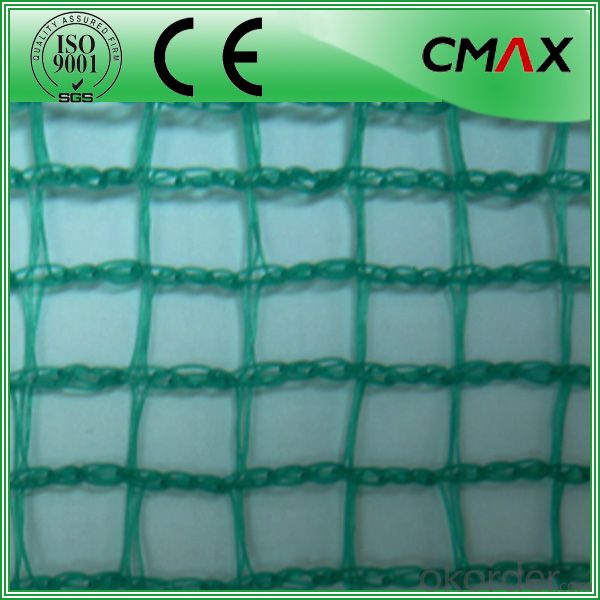

Production Description:

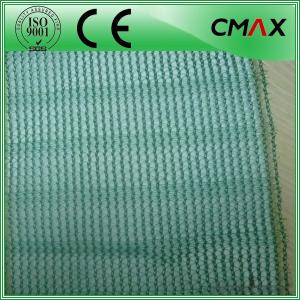

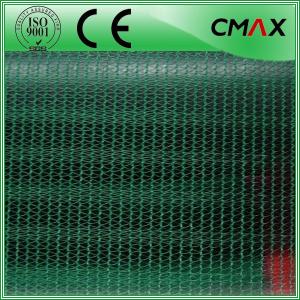

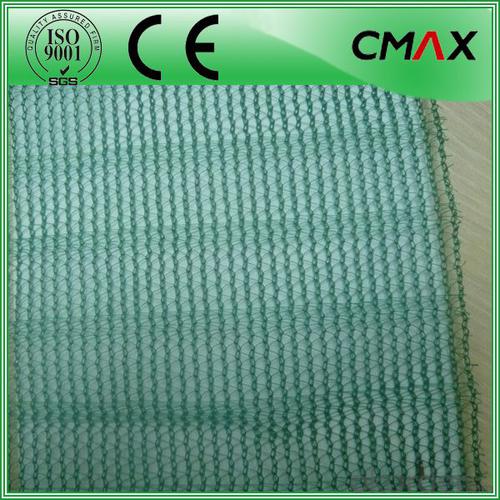

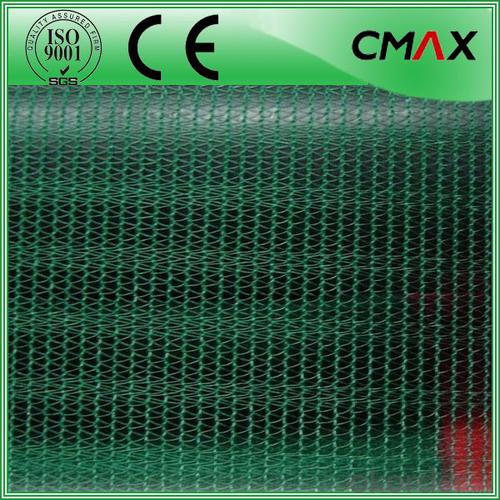

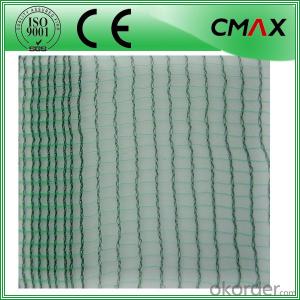

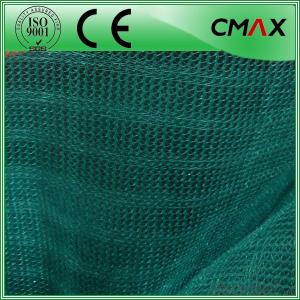

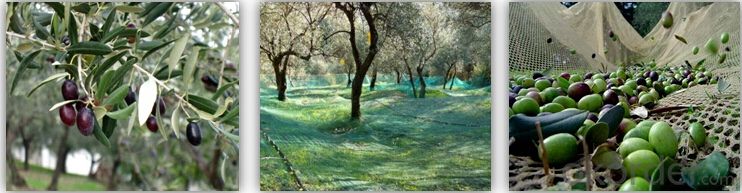

These nets are entirely made of UV stabilised polyethylene monofilament. The nets available have various kind of meshes in order to optimise the different harvesting methods of olives and fruits. Every net is suitable for a different application such as natural falling harvesting, hand harvesting or mechanised harvesting. The nets are available in different weights and colours and can be supplied in rolls or in sheets already stitched together with or without central vent.Olive collection net are used not only for the olive harvest, but also to gather chestnuts, nuts and deciduous fruits in general.

Produced with HDPE virgin material

UV stabilized - Long life

For Food : non-toxic, responsive to current European legislation on packaging for food.

Guarantee 5 years

Green&Black 50g/m2

Farmer used the net to gain olive from tree.

Specification:

| Type | CMAX-Olive Net |

| Weight | 33-200 gsm |

| Color | Black, Green, Dark Green, etc |

| Width,Length | 1-6m, 50m,100m as your requirements |

| Raw material | 100% Virgin HDPE with U.V Stabilized and irganox |

| Using life | At least 4 years |

| Delivery time | 30 days after deposit |

| Specification | construction(/inch) Warp=3, Weft=4.5, Br.Str.(kg) ,Warp=10, Weft=2 ,Screening factor(%) :10% |

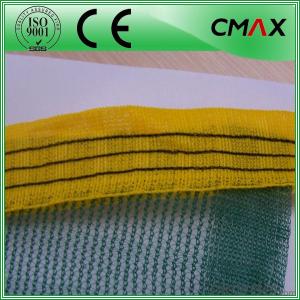

| Packing | rolls with PVC suare tube(5×5cm)/double folded/PE Stretch film/label |

| OEM | If you have your own packing design,we can quickly meet your requirments. |

Application:

Process:

Shipping&Packing:

Delivery Time: 20 Working Days After Confirmed P.O.

Packaging: Each piece packed in plastic bag, and several pieces per bale with PP woven bag outside, or in rolls with inner paper tube with plastic bag outside.

FAQ:

1.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shanghai, China. You can take flight to Shanghai Hongqiao airport, and 25 mins reach to our factory.

2.Q:What is the material of your products?

A: We use the raw material of High Density Polyethylene (HDPE) with UV Stabilized & Igranox to make our netting

3.Q:How does your factory do regarding quality control?

A: we are very proud to let you know that , We use the best raw material , have at least 5years experienced workers,

the advanced machine and specialized team to assure the quality

We perform Quality Control inspections on 100% of our products.

Our inspection standards are strictly in accordance with the ISO9001 certification system.

- Q: How do I prevent ground cover from becoming invasive?

- One way to prevent ground cover from becoming invasive is to choose non-invasive species that are well-suited to your specific climate and soil conditions. Additionally, regular monitoring and maintenance, such as trimming or thinning out the ground cover, can help prevent it from spreading uncontrollably. It is also important to avoid planting ground cover near native or sensitive plant species to prevent competition and potential invasiveness.

- Q: This question asks for a comparison between agricultural plastic mulch and other methods used for soil conservation, highlighting their differences.

- <p>Agricultural plastic mulch is a method of soil conservation that involves covering the soil with a thin layer of plastic to reduce weed growth, retain moisture, and regulate soil temperature. Unlike other soil conservation methods such as contour farming, terracing, or crop rotation, plastic mulch is a non-biological approach that doesn't involve changing the landscape or crop patterns. It's more about managing the microclimate around the plants. Other methods like cover cropping or no-till farming focus on building soil health and reducing erosion through biological means. Plastic mulch is often used for specific crops and seasons, while other conservation methods are more general and can be applied to a variety of agricultural settings.</p>

- Q: How do you prevent ground cover plants from spreading into lawn areas?

- One effective way to prevent ground cover plants from spreading into lawn areas is by installing a physical barrier like edging or plastic borders between the two areas. This creates a clear separation and prevents the plants from encroaching onto the lawn. Regular maintenance such as trimming and pruning the ground cover plants can also help control their growth and prevent them from spreading too far.

- Q: I accidently used a plastic tray for cookies and put it in the oven. When I thought the cookies were ready-I was right, but the plastic metled and the cookies were MUSH. How do I get rid of the plastic and cookie mush? PLEASE HELP ME!

- Depending on the type of plastic that's involved, you can begin to clean your oven while it's still warm and the plastic is still pliable. Sometimes, though, the plastic is so runny that it's near impossible to effectively clean it up. And other times, it's best to let the plastic cool down until it's hard again. . Remove the racks let cool and then use a plastic spatula or flat scraper to carefully remove as much of the plastic that is stuck to the bottom of your oven. If that doesn't work, then you'll need to turn your oven on and set it at a low temp... Wait a few minutes and allow the heat to soften the plastic up some...the plastic should scrape off easily. Wipe up any residue with a soft damp cloth..... You might have to replace the oven racks and allow the low heat to soften up the melted plastic...then, remove the racks and pull the plastic off with your fingers. Wipe any remaining plastic off with a damp cloth. If there's still some plastic residue on the racks, moisten a SOS soap pad or wire brush/steel wool.....and run it up and down the rungs. If that still doesn't do the trick...you can carefully use a razor blade... Good luck........

- Q: This question asks for methods to efficiently recycle agricultural plastic products.

- <p>To recycle agricultural plastic products efficiently, follow these steps: 1) Collect and sort the plastic waste by type and color. 2) Clean the plastic to remove dirt and contaminants. 3) Compact or shred the plastic into smaller pieces for easier transportation. 4) Use mechanical or chemical processes to break down the plastic into raw material form. 5) Reprocess the raw material into new plastic products. 6) Implement proper waste management practices on the farm to reduce plastic waste generation. 7) Encourage the use of biodegradable plastics in agriculture. 8) Collaborate with local recycling centers and waste management facilities to ensure proper disposal and recycling. 9) Educate farmers and the community about the importance of recycling agricultural plastics. 10) Advocate for policies that support recycling and the development of eco-friendly alternatives.</p>

- Q: How do you choose ground cover for a tropical rainforest garden?

- When choosing ground cover for a tropical rainforest garden, it is important to consider several factors. First, opt for native plant species that are well adapted to the local climate and soil conditions. This ensures they will thrive in the rainforest environment. Additionally, consider the specific needs of the garden, such as the desired aesthetic, level of maintenance required, and the purpose of the ground cover (e.g., erosion control, weed suppression). Lastly, select ground covers that provide benefits to the overall ecosystem, such as attracting pollinators or providing habitat for native wildlife.

- Q: Can farmers opt for biodegradable mulch materials as an alternative to traditional plastic mulch films in agricultural practices?

- <p>Yes, farmers can use biodegradable mulch materials as an alternative to agricultural plastic mulch film. These materials, such as straw, wood chips, or specially designed biodegradable plastics, can help retain soil moisture, suppress weeds, and maintain soil temperature, similar to plastic mulches. They offer environmental benefits by reducing plastic waste and are more sustainable. However, the effectiveness and longevity of biodegradable mulches can vary, and they may require more frequent replacement compared to plastic mulches. It's important for farmers to consider the specific needs of their crops and local conditions when choosing mulch materials.</p>

- Q: Do nursery trays come with a humidity control dome?

- Some nursery trays may come with a humidity control dome, but it depends on the specific product and manufacturer. It is important to check the product description or contact the supplier to confirm if a humidity control dome is included.

- Q: How do you prevent ground cover from smothering other plants?

- One effective way to prevent ground cover from smothering other plants is by regularly pruning and thinning out the ground cover to control its growth. This allows for better air circulation and sunlight penetration, reducing the risk of smothering. Additionally, creating physical barriers such as mulch or edging can help contain the ground cover and prevent it from spreading excessively.

- Q: This question asks about the various kinds of plastic films used in agriculture and their respective purposes.

- <p>Agricultural plastic films are used for a variety of purposes in farming. These include mulch films which help in weed control and moisture retention, greenhouse films that provide a controlled environment for plant growth, silage films for preserving forage crops, and nursery films for protecting young plants. There are also biodegradable films that decompose naturally to reduce environmental impact, and UV-stabilized films designed to withstand exposure to sunlight without breaking down. Each type of film serves a specific function, from improving crop yield to enhancing the quality of agricultural products.</p>

Send your message to us

Olive Collection Olives Nets for Farms Net

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords