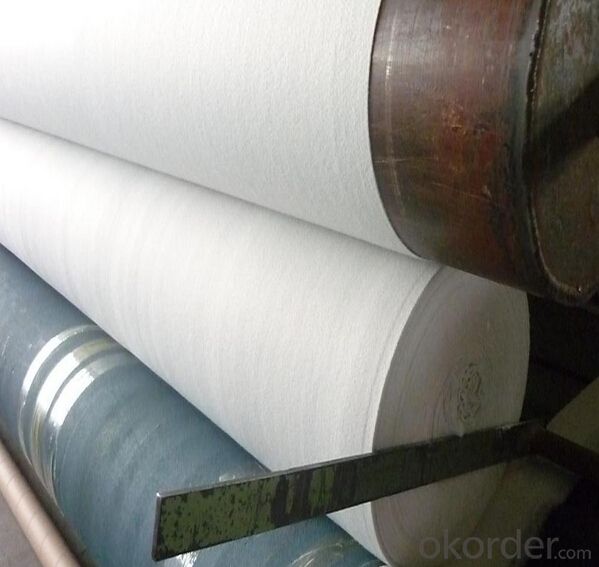

Nonwoven Geotextile/Geotextiles Factory Price

- Loading Port:

- Wenzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nonwoven Geotextile/Geotextiles Factory Price

Desciriptions:

Geotextile can avoid the sharps objects damage to pipeline and others buried underground.

Geotextile can reinforce the roadbed,slow down the pavement fracture.

Characteristics:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- There are several considerations for geotextile selection in road rehabilitation projects. Firstly, the geotextile should have the appropriate tensile strength to withstand the anticipated loads and stresses in the road structure. Additionally, it should have the proper permeability to allow for effective drainage and prevent water accumulation. The geotextile should also be resistant to chemical degradation and have good durability to ensure a long service life. Finally, factors such as cost, availability, and ease of installation should also be taken into account when selecting a geotextile for road rehabilitation projects.

- Q: What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on factors such as the quality of the material, the specific application, and the environmental conditions. However, on average, geotextiles are designed to have a lifespan of 20-30 years.

- Q: How do geotextiles help with separation and stabilization in railroads?

- Geotextiles are used in railroads to provide separation and stabilization. They help by creating a barrier between the different layers of materials used in railroad construction, preventing them from mixing or shifting. This separation ensures proper drainage and prevents the loss of fine particles. Additionally, geotextiles enhance the stability of the railroad by distributing loads more evenly, reducing the potential for settlement or deformation. Overall, geotextiles play a crucial role in maintaining the integrity and longevity of railroads.

- Q: What are the different geotextile filter criteria?

- The different geotextile filter criteria include permeability, retention, durability, and compatibility with the surrounding soil or materials.

- Q: How do geotextiles improve the performance of geocomposites?

- Geotextiles improve the performance of geocomposites by enhancing their strength, durability, and filtration capabilities. They act as a reinforcement layer, distributing the load and preventing the geocomposite from shifting or deforming under stress. Additionally, geotextiles provide filtration, allowing water to flow through while retaining soil particles, which helps in preventing clogging and maintaining the long-term performance of the geocomposite.

- Q: What are the advantages of using geotextiles in landfill lining systems?

- There are several advantages of using geotextiles in landfill lining systems. Firstly, geotextiles act as a barrier, preventing the leakage and migration of hazardous substances from the landfill into the surrounding environment, thus protecting groundwater and adjacent ecosystems. Secondly, geotextiles enhance the stability and integrity of the landfill by providing reinforcement and preventing soil erosion, which can lead to slope failure and instability. Additionally, geotextiles offer excellent filtration properties, allowing for the efficient drainage of liquids within the landfill, reducing the buildup of pore pressure, and improving the overall performance of the system. Lastly, geotextiles are durable, resistant to chemical degradation, and have a long lifespan, making them a cost-effective and sustainable solution for landfill lining systems.

- Q: Where are geotextiles used?

- Geotextiles are used in various civil engineering and environmental applications, including road construction, erosion control, drainage systems, landfills, and retaining walls.

- Q: Can geotextiles be used in coastal erosion control projects?

- Yes, geotextiles can be used in coastal erosion control projects. Geotextiles are often used as a component of erosion control measures such as beach nourishment, shoreline stabilization, and revetments. They can help to stabilize the soil, prevent erosion, and protect coastal areas from wave action.

- Q: Geotextile seepage seams how to deal with

- Quick drying cement

- Q: What are the challenges associated with the installation of geotextiles?

- There are several challenges associated with the installation of geotextiles. Firstly, one challenge is ensuring proper placement and anchoring of the geotextile material. It requires skilled labor and precise positioning to avoid any wrinkles or folds that could compromise its effectiveness. Secondly, geotextiles are often installed in harsh environments, such as steep slopes or areas with high water flow. This can make it difficult to secure the geotextile and prevent it from shifting or being damaged during installation. Another challenge is the potential for clogging or blockage of geotextiles due to fine particles or sediment. This can reduce their permeability and overall effectiveness, requiring regular inspection and maintenance. Lastly, the selection of the appropriate geotextile material for a specific application is crucial. Factors such as soil type, load requirements, and environmental conditions need to be carefully considered to ensure the geotextile can withstand the intended use and provide the desired performance. Overall, proper installation techniques, site-specific considerations, and regular maintenance are essential to overcome the challenges associated with the installation of geotextiles and maximize their effectiveness.

Send your message to us

Nonwoven Geotextile/Geotextiles Factory Price

- Loading Port:

- Wenzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords