Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Filtration:

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

- Q: How do geotextiles help with filtration in stormwater management systems?

- Geotextiles help with filtration in stormwater management systems by acting as a barrier that prevents soil erosion and retains sediment and pollutants. They allow water to flow through while trapping particles, thus improving water quality and reducing the chances of clogging in drainage systems.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. Well, long-term perspective, then we must do a solid job every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem, this is the status of China's construction industry. But the debt owed sooner or later.

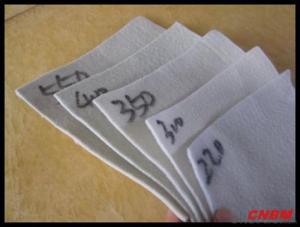

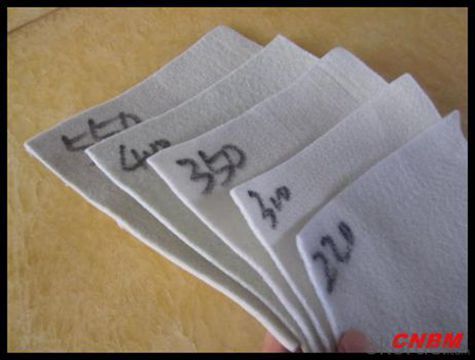

- Q: Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: What is a polyester filament geotextile? Polyester filament geotextile

- In addition to a good mechanical energy, but also has a good vertical and horizontal drainage and good extension of energy and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, also has a wide range of pore size, tortuous pore distribution, excellent permeability and filtration can be polyester filament geotextile purposes: water conservancy project dam and slope protection filter, channel isolation, seepage; Airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage; port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile Has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas. Polyester filament geotextile technical parameter table (GBT-1998): No. Remarks 1 unit area mass deviation% -6-6-6-5-5-5-5-5-4-4-42 thickness, mm ≥ 553 Width deviation% -054 breaking strength KNM ≥ vertical and horizontal 5 elongation at break% 40-806CBR breaking strength KN ≥ 707 equivalent aperture 090, mm007-02

- Q: How do geotextiles help with soil reinforcement in geogrid applications?

- Geotextiles help with soil reinforcement in geogrid applications by acting as a separation layer between the soil and the geogrid. They prevent the intermixing of different soil layers, which helps maintain the integrity of the geogrid by preventing soil displacement. Additionally, geotextiles enhance the overall performance of the geogrid by distributing the loads more evenly across the soil surface, reducing the potential for localized stress concentrations.

- Q: Can geotextiles be used in coastal reclamation projects?

- Yes, geotextiles can be used in coastal reclamation projects. Geotextiles are commonly used to stabilize soil and prevent erosion, making them an effective solution in coastal areas where erosion is a significant concern. These textiles can help to trap sediment, control water flow, and provide stability to newly reclaimed land, making them a valuable tool in coastal reclamation projects.

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: What are the benefits of using geotextiles in road construction?

- Geotextiles offer several benefits in road construction, including improved soil stabilization, increased road lifespan, and enhanced drainage. These synthetic fabrics act as a barrier, preventing the mixing of different soil layers, which helps to maintain the road's structural integrity. Geotextiles also provide reinforcement by distributing the load more evenly, reducing the occurrence of cracks and potholes. Additionally, these materials enhance drainage by allowing water to pass through while retaining the soil particles, preventing erosion and waterlogging. Overall, geotextiles contribute to cost-effective and sustainable road construction.

- Q: Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles can act as effective barriers, preventing the spread of contaminants, while still allowing water and air to pass through, facilitating the natural remediation process. Additionally, geotextiles can provide structural stability to the soil, preventing erosion and enhancing the overall effectiveness of the remediation project.

Send your message to us

Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords