High-Class Plastic Water Pipe Fittings for Hot and Cold Water with Tyre Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1.It is used in industrial fields, agriculture and garden irrigation.

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

Product Applications

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioners

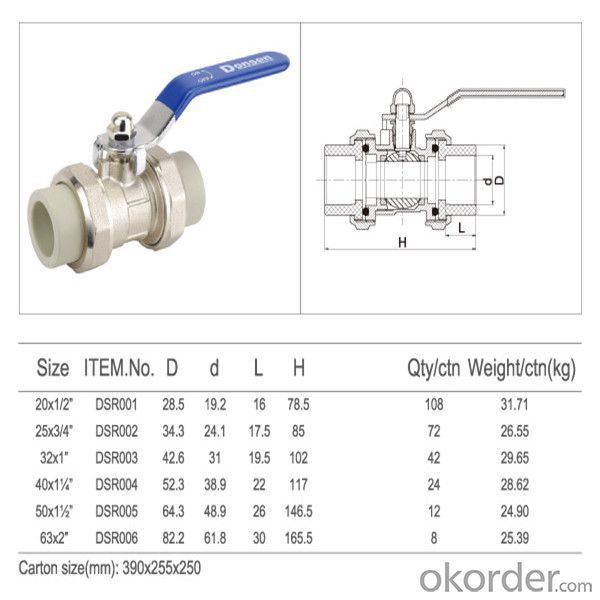

Product size

1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa | |

Outer | Wall | Wall | Wall | Wall |

Diameter | Thickness | Thickness | Thickness | Thickness |

dn(mm) | en (mm) | en (mm) | en (mm) | en (mm) |

20 | 2.0 | 2.3 | 2.8 | 3.4 |

25 | 2.3 | 2.8 | 3.5 | 4.2 |

32 | 2.9 | 3.6 | 4.4 | 5.4 |

40 | 3.7 | 4.5 | 5.5 | 6.7 |

50 | 4.6 | 5.6 | 6.9 | 8.3 |

63 | 5.8 | 7.1 | 8.6 | 10.5 |

75 | 6.8 | 8.4 | 10.1 | 12.5 |

90 | 8.2 | 10.1 | 12.3 | 15.0 |

110 | 10 | 12.3 | 15.1 | 18.3 |

160 | 14.6 | 17.9 | 21.9 | 26.6 |

Product Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q: Can plastic pipe fittings be used for food processing systems?

- No, plastic pipe fittings are not suitable for food processing systems as they can potentially leach harmful chemicals into the food, compromising its safety and quality. Stainless steel or food-grade materials are recommended for such applications.

- Q: Can plastic pipe fittings be used for steam systems?

- No, plastic pipe fittings should not be used for steam systems. Steam systems operate at high temperatures and pressures, which can cause plastic fittings to melt, deform, or fail. It is recommended to use metal pipe fittings, such as brass or steel, that are specifically designed for steam applications.

- Q: Can plastic pipe fittings be used for steam piping?

- No, plastic pipe fittings should not be used for steam piping. Steam piping requires materials that can withstand high temperatures and pressures, which plastic fittings are not designed to handle. Metal fittings, such as those made of steel or brass, are recommended for steam piping to ensure safety and durability.

- Q: Can plastic pipe fittings be used in mining applications?

- Yes, plastic pipe fittings can be used in mining applications. They are commonly used in mining for various purposes such as transporting water, chemicals, and slurry. Plastic fittings offer advantages such as corrosion resistance, lightweight construction, and ease of installation, making them suitable for mining environments.

- Q: How do plastic pipe fittings compare to CPVC fittings?

- Plastic pipe fittings and CPVC fittings have some similarities, but they also have notable differences. Plastic pipe fittings, which are usually made of PVC (Polyvinyl Chloride), are known for their durability and affordability. They are widely used for various applications, including plumbing, irrigation, and drainage systems. Plastic fittings are resistant to corrosion, chemicals, and UV radiation, making them suitable for both indoor and outdoor installations. However, they may not handle high temperatures as well as CPVC fittings. On the other hand, CPVC (Chlorinated Polyvinyl Chloride) fittings are specifically designed for hot water applications. They can withstand higher temperatures than plastic fittings without losing their structural integrity. CPVC fittings offer excellent heat resistance, making them ideal for hot water supply lines in residential and commercial buildings. However, compared to plastic fittings, CPVC fittings can be slightly more expensive. In summary, while plastic pipe fittings are versatile and cost-effective, CPVC fittings are better suited for hot water applications where higher temperatures are involved. The choice between the two depends on the specific requirements of the plumbing project.

- Q: Are plastic pipe fittings resistant to UV degradation?

- Yes, plastic pipe fittings can be resistant to UV degradation, depending on the type of plastic used. Some plastics, such as PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and PEX (cross-linked polyethylene), are specifically formulated to have UV resistance properties. These plastic materials are designed to withstand prolonged exposure to sunlight and prevent damage or degradation caused by UV rays. However, it is essential to choose the appropriate plastic material for specific applications and ensure that it is labeled as UV resistant if UV exposure is a concern.

- Q: Can plastic pipe fittings be used for irrigation systems in agricultural fields?

- Yes, plastic pipe fittings can be used for irrigation systems in agricultural fields. Plastic pipe fittings are commonly used in irrigation systems due to their durability, ease of installation, and resistance to corrosion. They are also cost-effective and compatible with various types of piping materials, making them a suitable choice for agricultural irrigation needs.

- Q: PVC what's the direct head of the outside pipe?

- Hello, PVC, the outside of the pipe is directly attached to the external tooth.Wire and teeth refers to the pipe metal parts of the thread, the outer wire is the outer thread of the pipe, is metal pipe and non-metallic (mainly refers to PP-R, PVC and other plastic pipes) directly connected pipe fittings.PVC water supply pipe and wire directly, as with the pipe connection.

- Q: What is the purpose of plastic pipe fittings?

- The purpose of plastic pipe fittings is to connect and secure pipes together, ensuring a leak-proof and reliable plumbing or piping system.

- Q: Do plastic pipe fittings require any special supports or hangers?

- Yes, plastic pipe fittings typically require special supports or hangers to ensure proper installation, stability, and to prevent sagging or stress on the pipes. These supports or hangers are designed to securely hold the pipes in place, maintain alignment, and distribute the weight evenly.

Send your message to us

High-Class Plastic Water Pipe Fittings for Hot and Cold Water with Tyre Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords